High-performance glass thinning glue and preparation method thereof

A high-performance, thin-adhesive technology, used in adhesives, modified epoxy resin adhesives, non-polymer adhesive additives, etc., can solve problems such as physical grinding methods that do not meet the requirements, and achieve good glass adhesion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

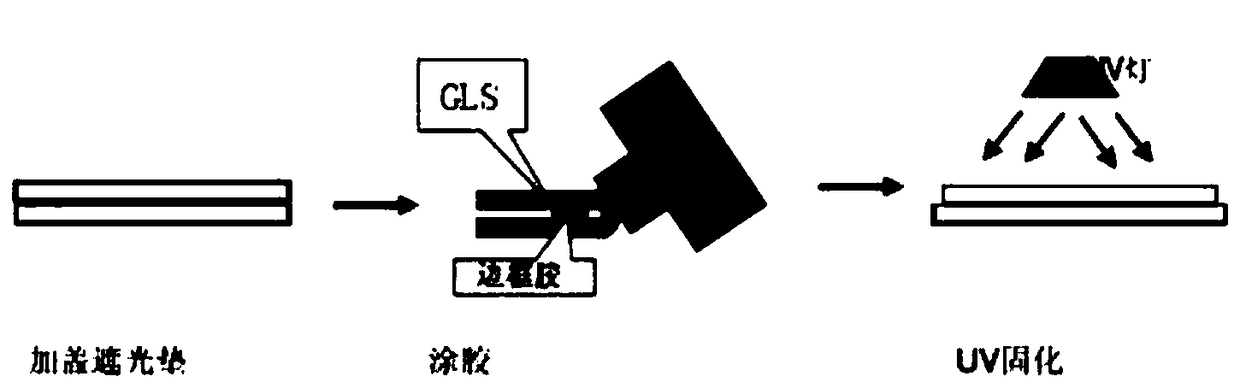

Method used

Image

Examples

Embodiment 1

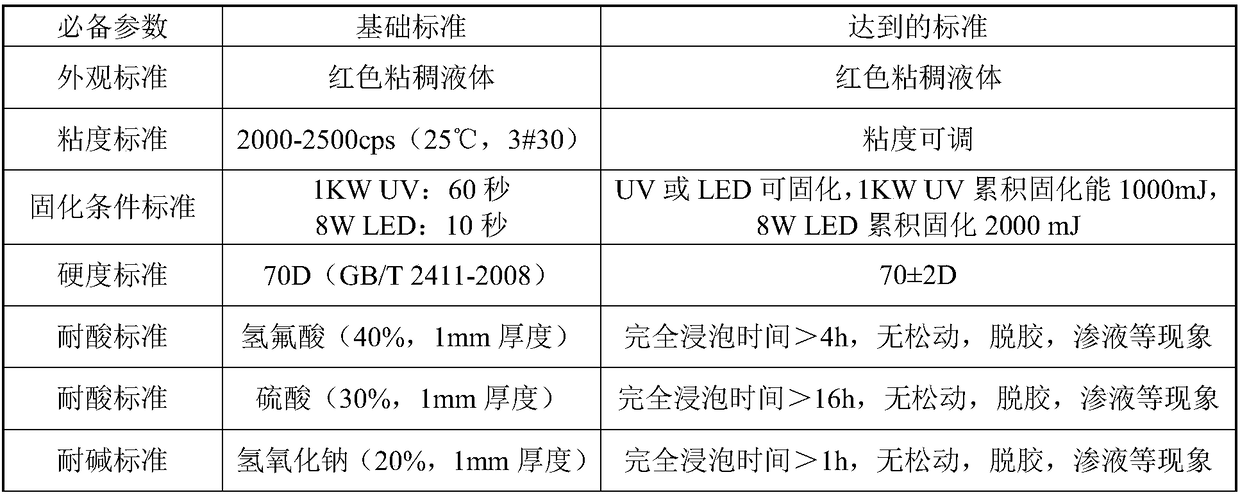

[0020] A preparation method of high-performance glass thinning glue, calculated in parts by mass, first weighs 15 parts of isobornyl acrylate, 10 parts of tetrahydrofurfuryl acrylate, 3 parts of acyl phosphine oxide and 1 part of benzoin, and mixes them, Heat to 40-50°C and stir at 1200-2000r / min for 40-45min. Then add 35 parts of urethane acrylate, 30 parts of pure acrylic resin, 5 parts of 2-functional epoxy acrylate and 0.8 parts of coupling agent in sequence, after stirring for 20-30 minutes, add 0.2 parts of wetting agent, and stir for 10-15 minutes. Filter with a 300-mesh filter, and pack the filtrate to obtain the glass-thinning glue. The performance of gained glass thinning glue is as follows:

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com