A kind of integrated construction device and method of 3D printing frp reinforced concrete structure

A technology of concrete structure and 3D printing, applied in the direction of building structure, construction, etc., to achieve the effect of improving the degree of freedom, high tensile strength, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

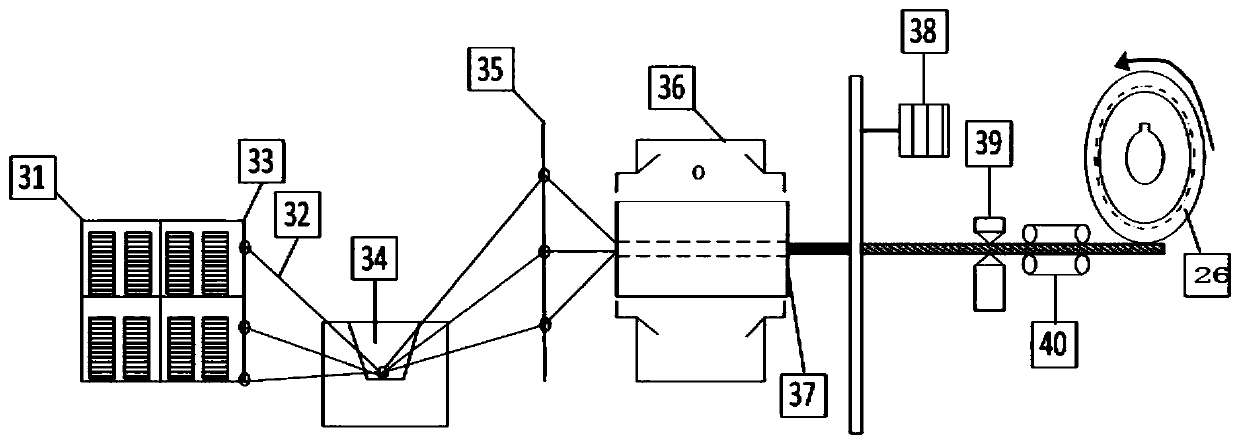

[0057] The preparation process of the FRP tendon is as follows: continuous fiber filament / rope bundle → fiber dipping → pultrusion forming through a heating mold → winding into a threaded surface → cooling forming → cutting → FRP tendon winding into a roll;

[0058] The continuous fiber filament / rope is any one or a combination of glass fibers, polypropylene fibers, basalt fibers, carbon fibers, and aramid fibers;

[0059] Said fiber impregnation, wherein the glue is any one of thermoplastic resins.

[0060] In this application, FRP bars are used instead of steel wire ropes. FRP bars are more flexible after heating, so the diameter of FRP bars can be much larger than that of steel wire ropes, which is beneficial to improve the effectiveness of FRP bars for concrete reinforcement. In the present invention, the diameter of the pultrusion die is not greater than 5mm, and the diameter of the FRP tendons used is not greater than 5mm, which is smaller than that of ordinary FRP tendo...

Embodiment 1

[0062] This embodiment takes the 3D printing of FRP reinforcement tailings sand fiber concrete structure printing as an example.

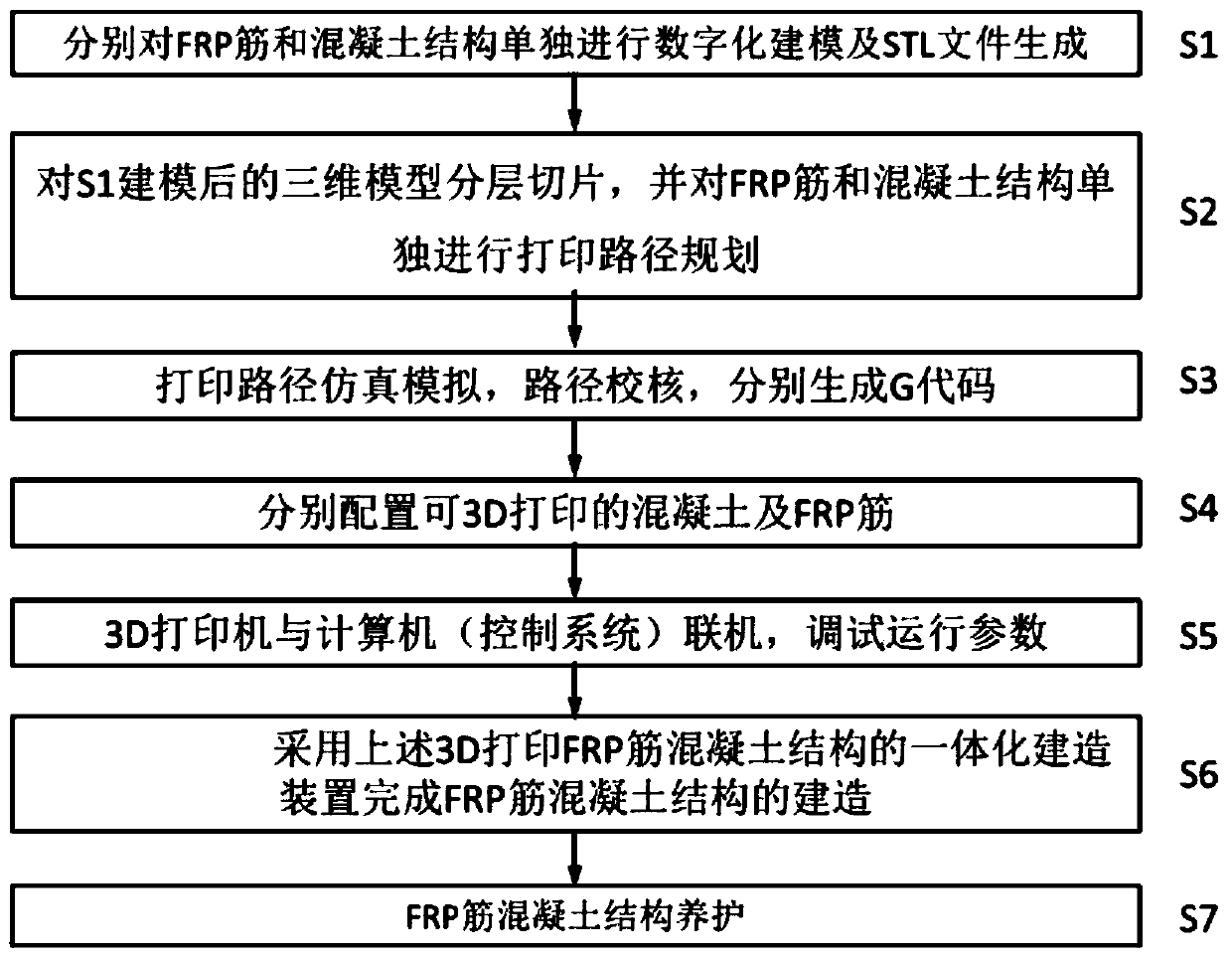

[0063] A kind of construction method of 3D printing FRP reinforcement tailings sand fiber concrete structure, the steps of this method are:

[0064] S1. Separate digital modeling and STL file generation for FRP bars and concrete structures;

[0065] Using Solidworks to digitally model the FRP bars and tailings sand fiber structures and export STL files.

[0066] S2. Slicing the three-dimensional model modeled in step S1 layer by layer, and separately printing path planning for FRP bars and concrete structures;

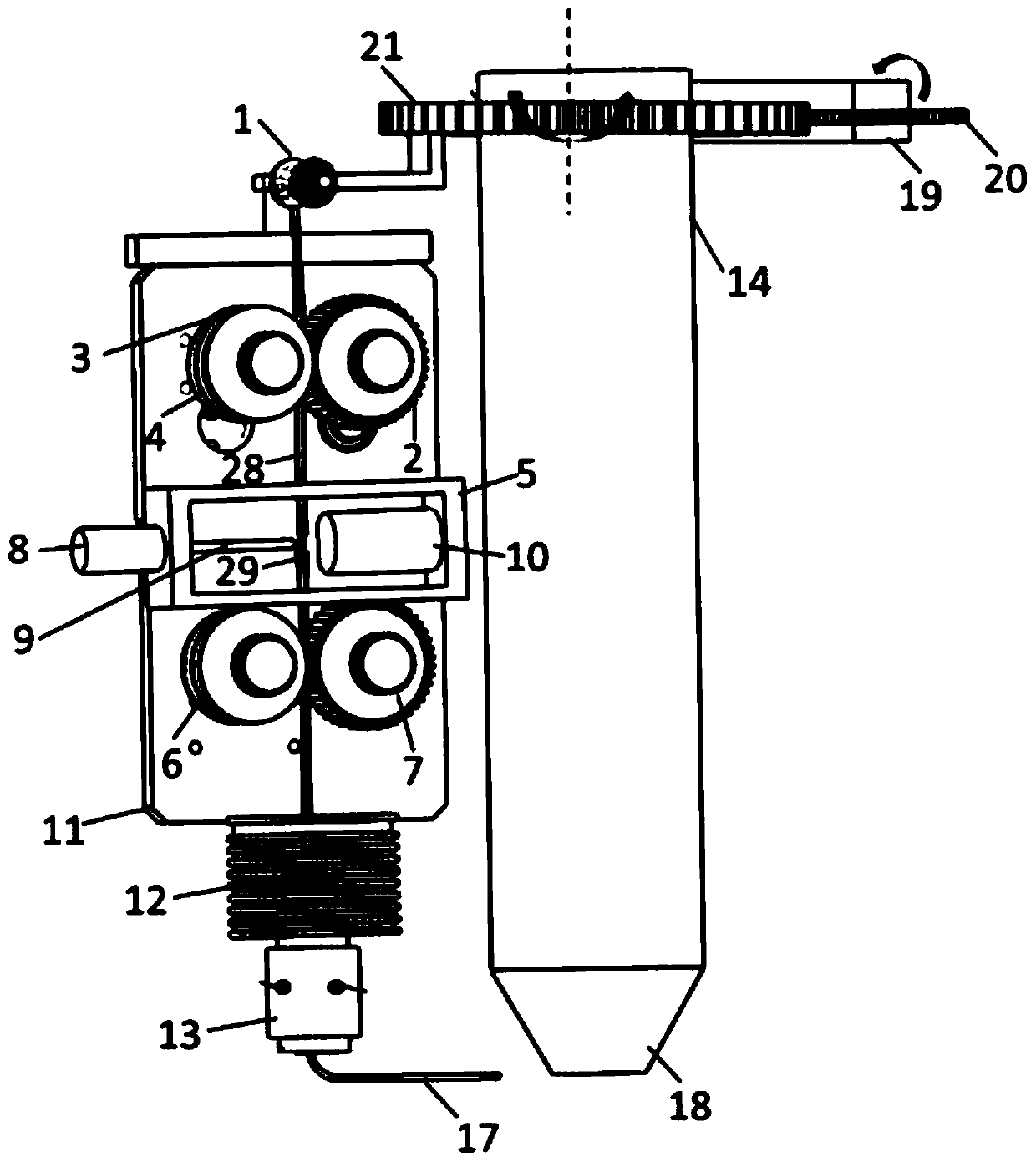

[0067] Use the 3D model slicing software Slic3r to slice the digital model of FRP bars and tailings sand fiber concrete. The diameter of the concrete printing head 18 is set to 12mm, the thickness of the first layer is 4mm, the thickness of the remaining layers is 5.5mm, and the printing speed is 45mm / s; using software Comes with concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com