A semiconductor silicon wafer rotary lithography machine

A silicon wafer and semiconductor technology, which is applied in the field of semiconductor silicon wafer rotary lithography machines, can solve the problem that the shock absorption effect of a shock absorber cannot achieve the expected effect, etc., so as to increase the shock absorption pressure, save the usage amount, and improve the usage. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

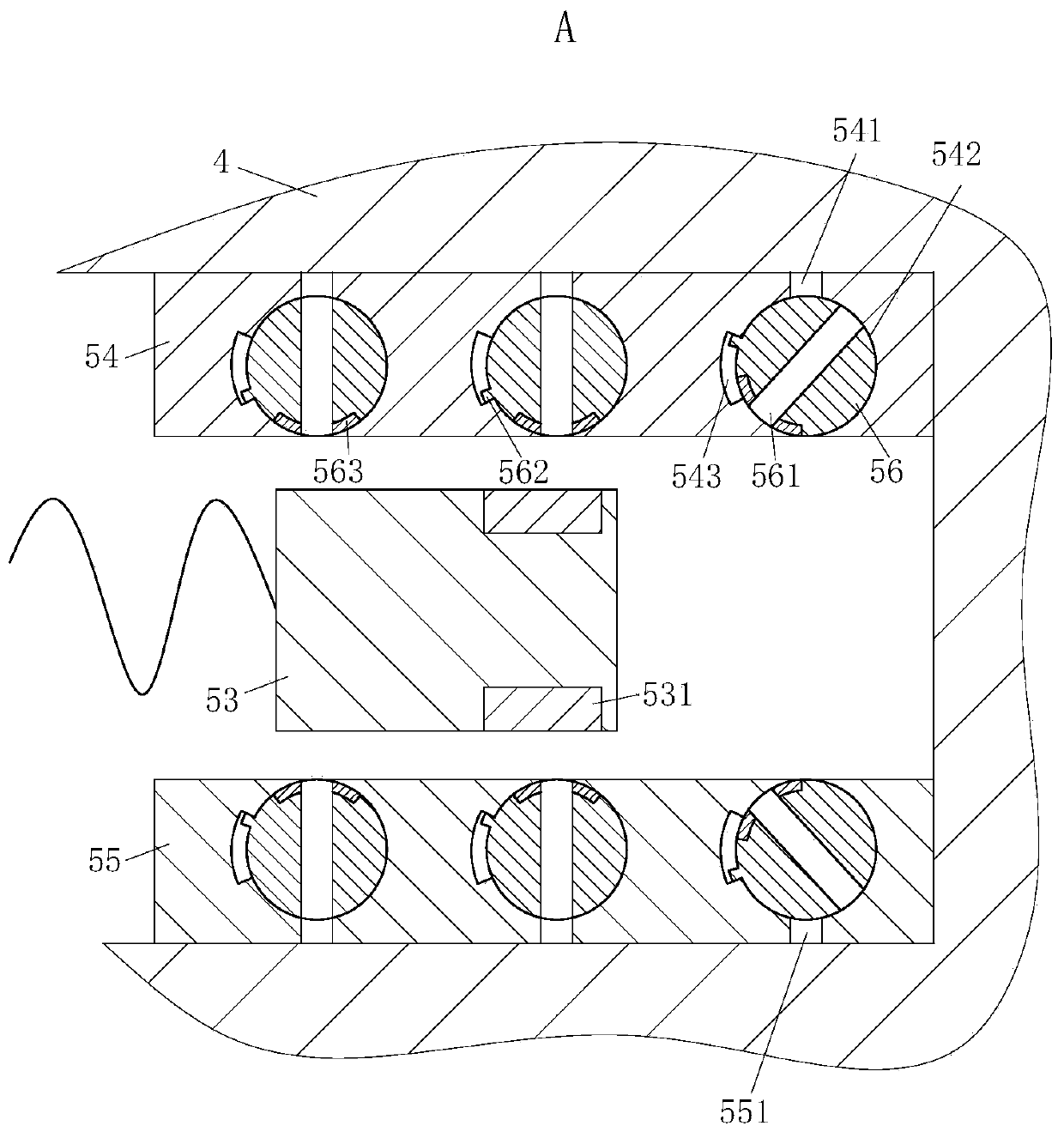

[0025] As an embodiment of the present invention, a No. 1 spherical cavity 542 is set in the No. 1 blowing hole 541 and No. 2 blowing hole 551; a No. 1 circular arc is set on the side of the No. 1 spherical cavity 542 close to the central turntable 52 Shape chute 543; Rotation block 56 is installed in the No. 1 spherical cavity 542; No. 4 blowing holes 561 are set inside the rotation block 56, and sliding boss 562 is set on the side of rotation block 56 near the center turntable 52; The sliding boss 562 slides in the No. 1 arc-shaped chute 543; the No. 4 air blowing hole 561 is embedded in a circular spherical magnet 563 near the outlet of one end of the balance weight 53; the upper and lower surfaces of the balance weight 53 are embedded with magnets 531 . The higher the motor speed, the greater the centrifugal force on the balance weight 53, the farther the balance weight 53 from the center of rotation, the farther the distance, the more openings on the upper and lower air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com