Ice coating simulation method for 220kV transmission line tower-coupling system

A technology of a transmission line tower and a simulation method, applied in the field of transmission lines, can solve the problems of insufficient consideration of inertia, offset of linear tower insulators, neglect of sub-conductor coupling, etc., and achieves short modeling period, fine model and high calculation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples illustrate the implementation process of the present invention.

[0046] This embodiment is a tension section of a 220kV single-circuit overhead transmission line in Jiangxi Power Grid. The tension section contains three base iron towers, the middle iron tower is a straight tower, the model is ZMC4-27; the two end towers are tension towers, the model is JCI-30. The left and right spans are 137m and 462m respectively. The wires are two split wires arranged vertically, the wire model is 2×JL / G1A-300 / 40, the ground wire model is OPGW-36B1-120, and the ground wire model is JLB35-120.

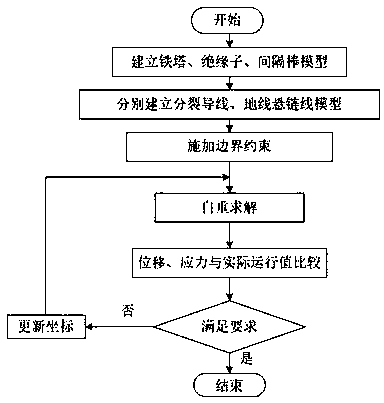

[0047] The icing simulation method of the transmission line tower-line coupling system in this embodiment mainly includes the following steps:

[0048] Step 1: Establish a finite element model of the transmission line tower-line coupling system;

[0049] Step 1-1: Modeling the transmission tower

[0050] Using the APDL language of ANSYS software to model the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com