Method for treating phenolic wastewater in petrochemical engineering

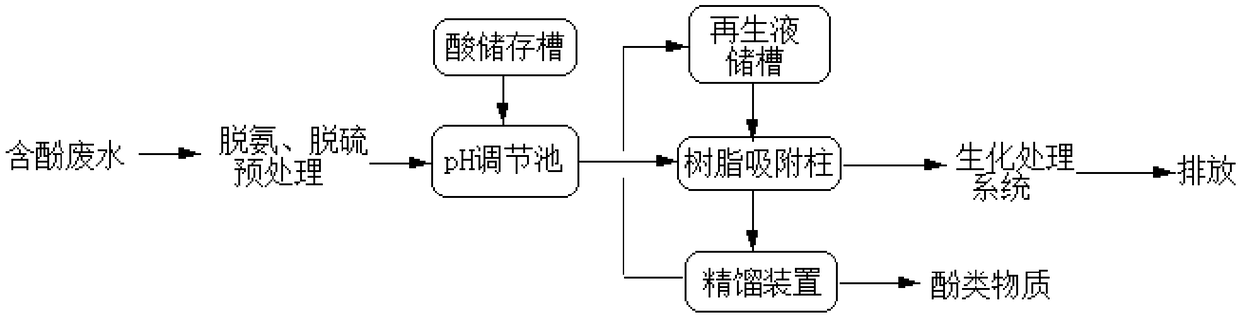

A petrochemical and treatment method technology, which is applied in the treatment of petrochemical phenol-containing wastewater and in the field of environmental protection, can solve the problems of high treatment cost and high dosing amount, and achieve the effect of simple treatment method, high environmental protection benefit, and cost-effective treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The non-polar macroporous adsorption resin of styrene-divinylbenzene system is pretreated with 2 times the resin volume of absolute ethanol, and after removing impurities such as monomers remaining in the resin during the synthesis of the macroporous adsorption resin, use 3 times the resin volume The pretreated resin was packed in an adsorption column with a height-to-diameter ratio of 20, and the two-stage adsorption column was connected in series, and the air bubbles in the adsorption column after filling the resin were removed with water.

[0028] Pretreat the wastewater with a phenol content of 750mg / L in the petrochemical production line, adjust the pH to 3.6 with 10% HCl, pass the adjusted pH phenol-containing wastewater into the adsorption column for dephenolization treatment, and control the phenol-containing wastewater The volume flow rate is 10 times the resin volume / hour, the linear flow rate is about 8.4m / h, and the volatile phenol content in the effluent is ...

Embodiment 2

[0031] The non-polar macroporous adsorption resin of styrene-divinylbenzene system is pretreated with 2 times the volume of anhydrous methanol to remove impurities such as monomers remaining in the resin during the synthesis of the macroporous adsorption resin, and then use 3 times the volume of the resin The pretreated resin was packed in an adsorption column with a height-to-diameter ratio of 30, and the two-stage adsorption column was connected in series, and the air bubbles in the adsorption column after filling the resin were removed with water.

[0032] Pretreat the wastewater with a phenol content of 1000mg / L in the petrochemical production line, adjust the pH to 4.5 with 10% HCl, pass the adjusted pH phenol-containing wastewater into the adsorption column for dephenolization treatment, and control the phenol-containing wastewater The volume flow rate is 5 times the resin volume / hour, the linear flow rate is about 5.2m / h, and the volatile phenol content in the effluent i...

Embodiment 3

[0035] The adsorption column after the regeneration of the resin in Example 2 is used as the second section in series to the first section and then continues to operate to treat phenol-containing wastewater.

[0036]Pretreat the wastewater with a phenol content of 1000mg / L in the petrochemical production line, adjust the pH to 5.0 with 12% HCl, pass the adjusted pH phenol-containing wastewater into the adsorption column for dephenolization treatment, and control the phenol-containing wastewater The volume flow rate is 6 times the resin volume / hour, the linear flow rate is about 6.2m / h, and the volatile phenol content in the effluent is less than 0.1mg / L.

[0037] The purified water after dephenolization enters the biochemical system for biochemical treatment and is finally discharged. When the volatile phenol content in the effluent is >0.1mg / L, regenerate the resin with the methanol regeneration solution recovered after 2 times rectification, and control its volume flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com