Thermal barrier coating with thermal barrier and anti-CMAS corrosion attachment and preparation process of thermal barrier coating

A technology of thermal barrier coating and preparation process, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., and can solve the problems of weakening the cooling effect of superalloys, clogging of cooling air film holes, and damage to metal substrates , to achieve the effect of reducing the depth and speed of vertical penetration, strong feasibility, and long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]A preparation process of a thermal barrier coating with both thermal barrier and anti-CMAS corrosion adhesion, comprising the following steps:

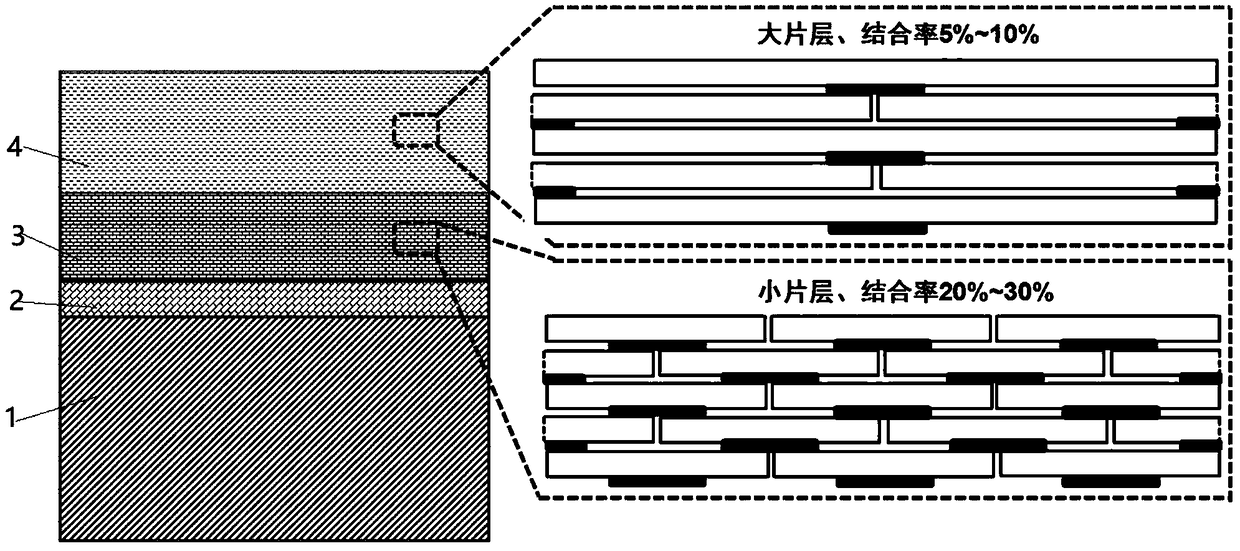

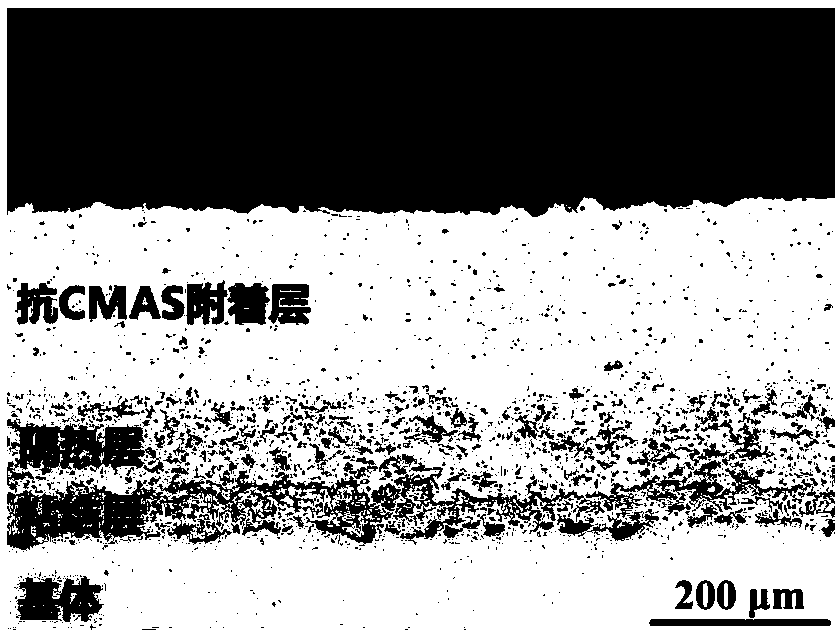

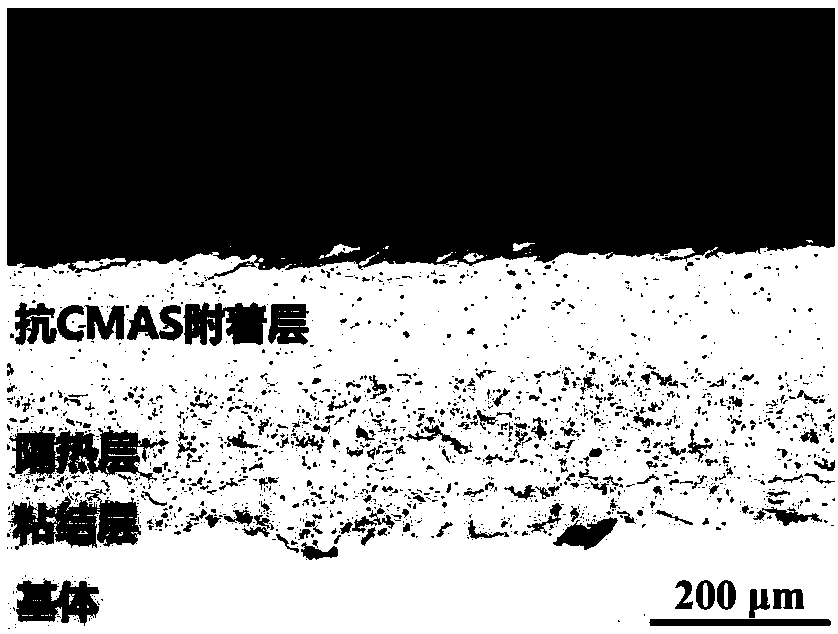

[0035] On the surface of the superalloy substrate and its bonding layer, use 8YSZ spray powder with a particle size of 45 μm to 75 μm, and spray through atmospheric plasma technology to prepare a layered ceramic heat insulation layer with a bonding rate of 25% to 30% and a thickness of 100 μm; heat insulation The laminar unit of the layer has a lateral dimension of 8 to 20 μm and a longitudinal dimension of 0.8 to 2.5 μm. Then, lanthanum zirconate powder (LZO) with a particle size of 50 μm to 100 μm was used to prepare a layered ceramic anti-CMAS corrosion adhesion layer by atmospheric plasma spraying; The thickness is 0.8-2.5 μm, and the bonding rate of adjacent sheet units along the thickness direction of the thermal barrier coating is 5%-10%. In the process of preparing the anti-CMAS corrosion adhesion layer by spraying, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com