Downhole movable slurry casting device and method

A grouting device and mobile technology, applied in the field of geotechnical engineering, can solve the problems of affecting the smooth development of fire prevention and extinguishing work, affecting the use effect of slurry concentration, and difficult to match the water intake in time, so as to save manpower and material resources, simple structure, The effect of driving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

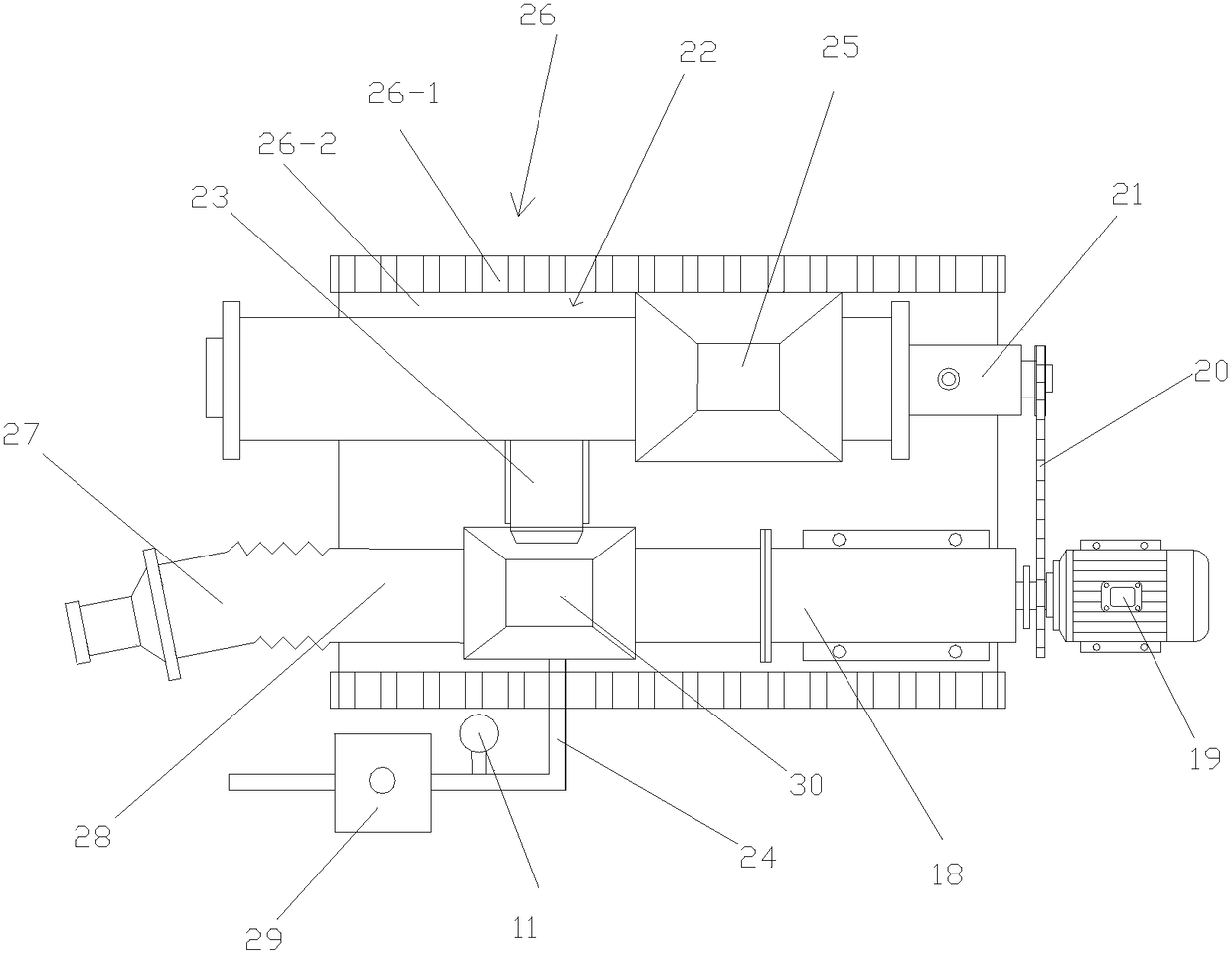

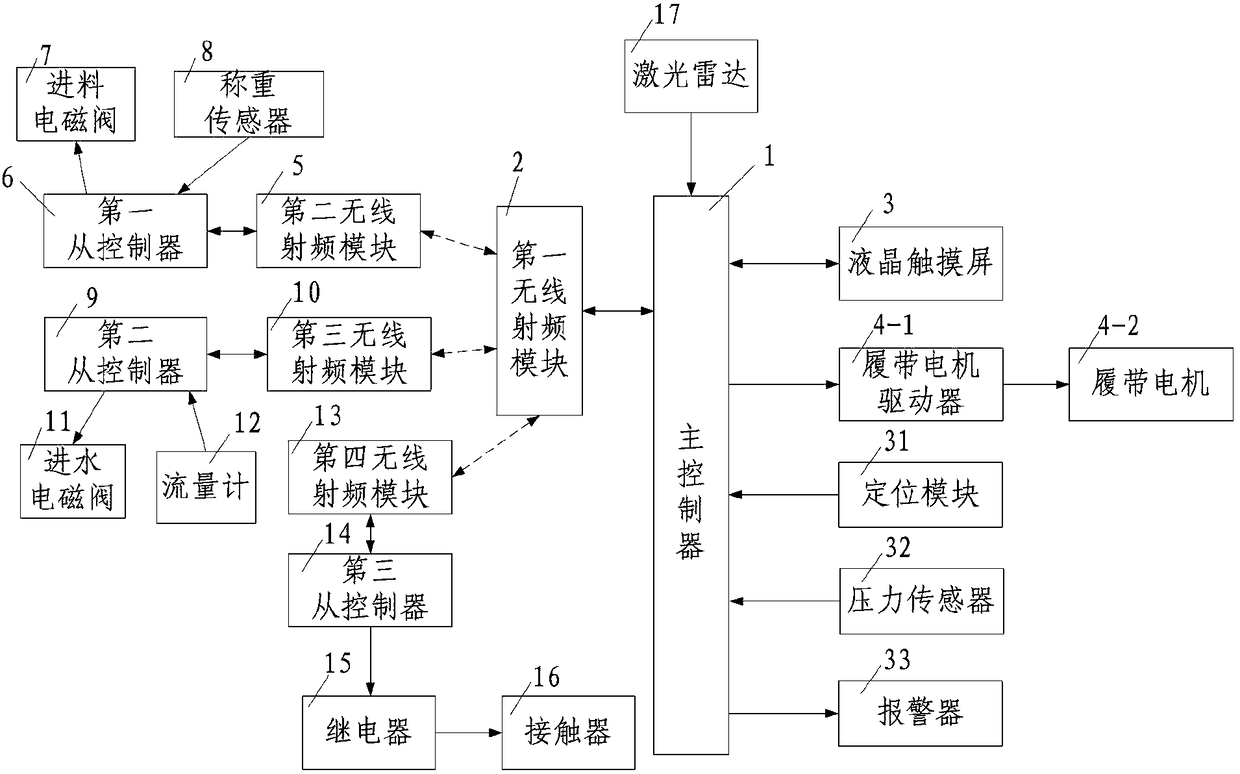

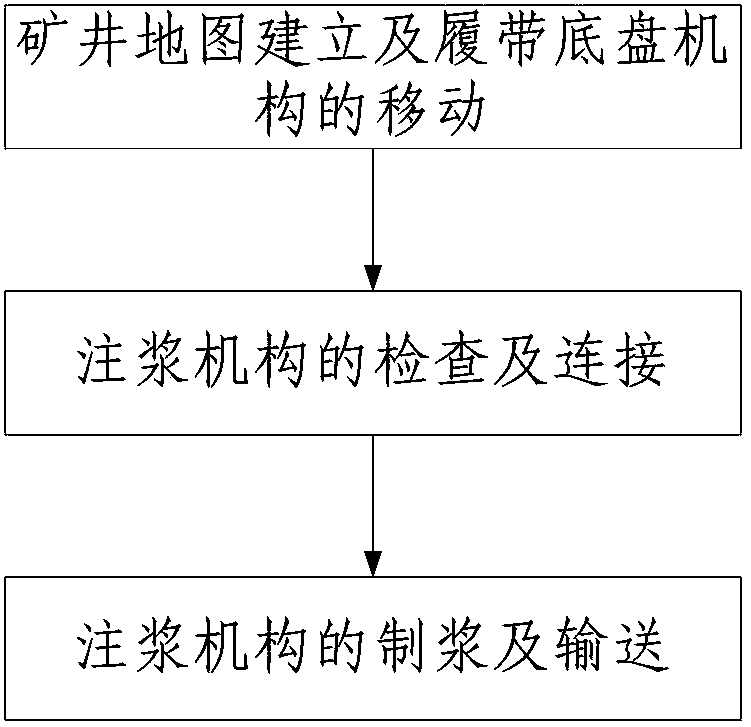

[0050] Such as figure 1 and figure 2 The shown mobile grouting device includes a crawler chassis mechanism 26, a grouting mechanism arranged on the crawler chassis mechanism 26, and a monitoring monitor for monitoring the crawler chassis mechanism 26 and the grouting mechanism. module, the grouting mechanism includes a feeding structure and a grouting mechanism, and the crawler chassis mechanism 26 includes a chassis 26-2, a crawler belt 26-1 installed on the chassis 26-2 and driving the crawler belt 26-1 Rotating crawler drive module, the pulping mechanism includes a mixing tank 30, a screw pump 18 extending into the mixing tank 30, and an explosion-proof motor 19 that drives the screw pump 18 to rotate to make slurry and is transmission-connected to the feeding structure , the feeding structure includes a feeding assembly 22 for feeding the mixing box 30, a feeding port 25 arranged on the feeding assembly 22 and a discharge platform 23 arranged on the feeding assembly 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com