Internal combustion engine supercharging system integrated with waste heat recovery

A waste heat recovery system and waste heat recovery technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as undiscovered technical solutions, achieve energy conservation and emission reduction, energy security, improve power and economy, and significantly economical The effect of benefits and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

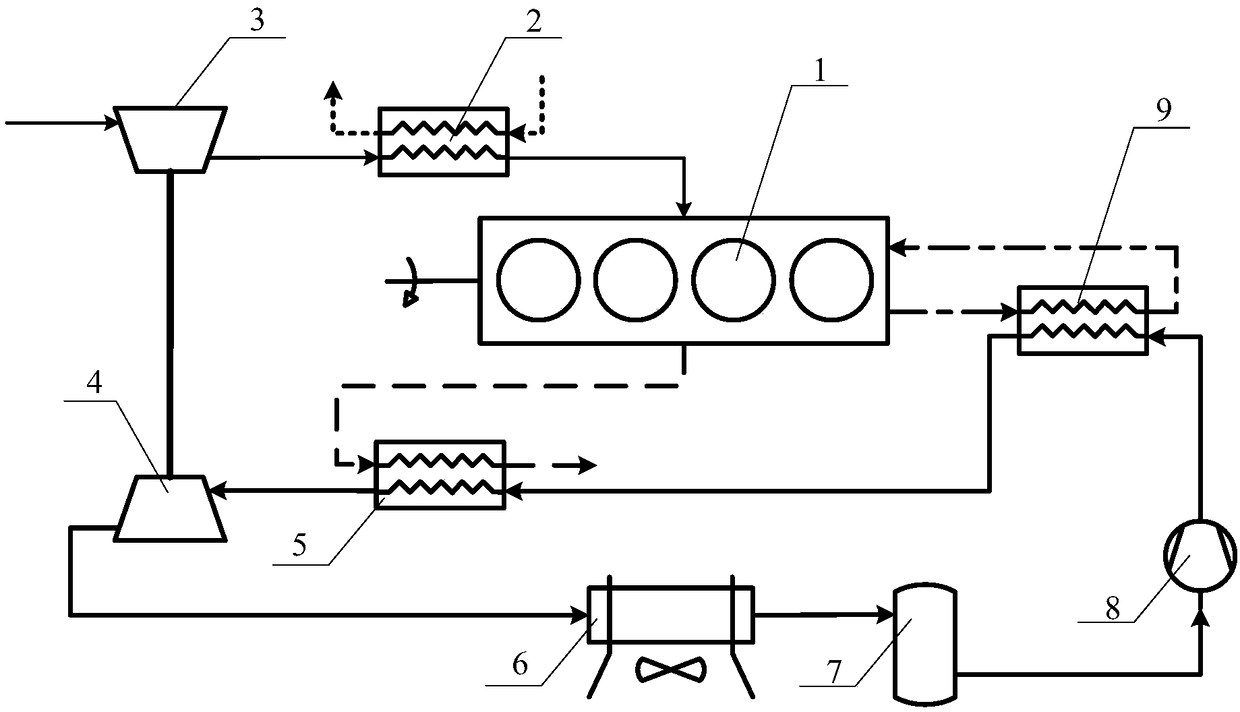

[0026] like figure 1 As shown, the present invention proposes an internal combustion engine supercharging system integrating waste heat recovery, including an internal combustion engine 1, an intercooler 2, a compressor 3 and a turbocharger 4, and the turbocharger 4 is the same as the compressor 3 The compressor 3 is connected to the internal combustion engine 1 through the charge air side of the intercooler 2, and the turbocharger 4 is driven by a waste heat recovery system based on Rankine Circulating power cycle system, including cooler 6, working medium tank 7, compressor 8, jacket water heat exchanger 9, flue gas heat exchanger 5 connected in series, the outlet of the compressor 8 is connected to the cylinder The working medium side inlet of the jacket water heat exchanger 9, the working medium side outlet of the jacket water heat exchanger 9 is connected to the working medium side inlet of the flue gas heat exchanger 5, and the flue gas heat exchanger 5 The outlet on th...

Embodiment 2

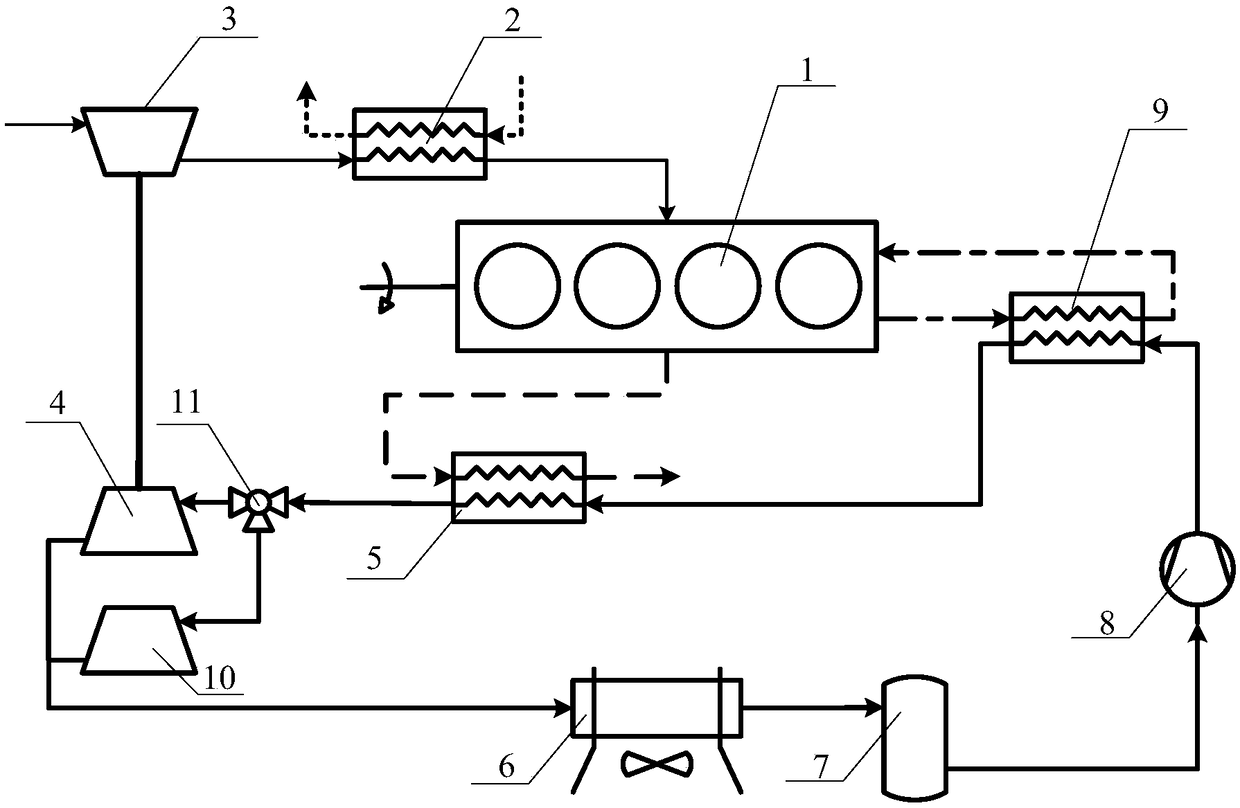

[0030] like figure 2 As shown, embodiment 2 adds an expander 10 on the basis of embodiment 1, that is, a three-way solenoid valve 11 is provided on the pipeline between the flue gas heat exchanger 5 and the turbocharger 4, so A three-way is provided on the pipeline between the supercharging turbine 4 and the cooler 6, and an expander 10 is connected between the three-way solenoid valve 11 and the three-way through a connecting pipeline. In this embodiment, in order to make full use of the exhaust energy of the internal combustion engine, by adding a three-way solenoid valve 11 and an expander 10, the system is divided into a supercharging branch realized by the turbocharger 4 and a power split realized by the expander 10. In this way, the exhaust energy that meets the supercharging needs of the internal combustion engine is converted into output work or electric energy or used as auxiliary power for the vehicle.

[0031] Compared with Embodiment 1, the working process of the...

Embodiment 3

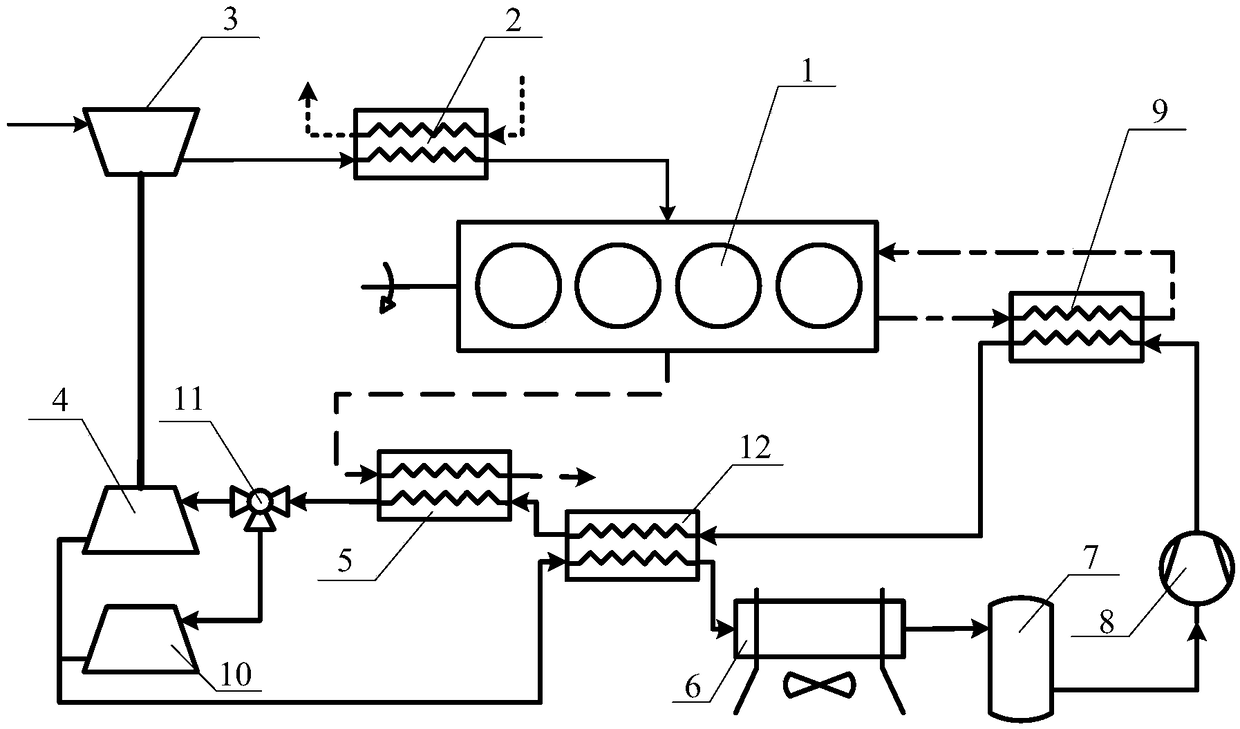

[0034] like image 3 As shown, in order to further recover the exhaust gas energy of the working medium after expansion, the embodiment 3 is based on the embodiment 2 and also includes an intermediate heat exchanger 12, and the outlet of the working medium side of the jacket water heat exchanger 9 passes through The high-pressure working medium side of the intermediate heat exchanger 12 is connected to the working medium-side inlet of the flue gas heat exchanger 5, and the outlet of the tee is connected after passing through the low-pressure working medium side of the intermediate heat exchanger 12 to the cooler 6.

[0035] Compared with Embodiment 2, the working process of the system in Embodiment 3 is only different: the low-pressure working fluid after the three-way confluence enters the intermediate heat exchanger 12 and the high-pressure working fluid at the outlet of the jacket water heat exchanger 9 to exchange heat and then enters the cooler 6.

[0036] The character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com