Two-dimensional magnetic field sensor

A two-dimensional magnetic field and sensor technology, which is applied in the field of magnetic sensors, can solve the problems of occupying a large space, measurement system error, and complicated process, and achieve the effects of easy miniaturization, high precision, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

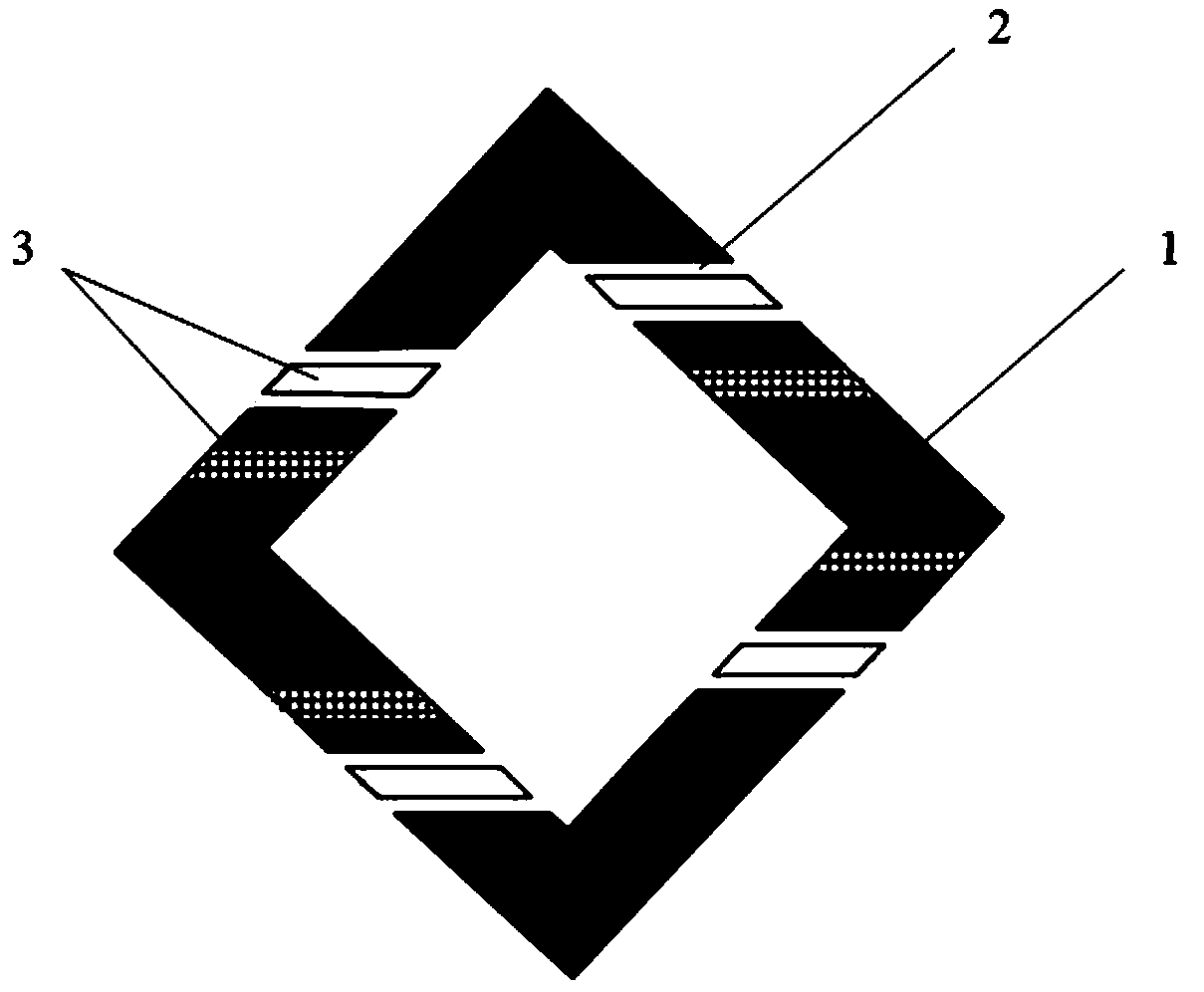

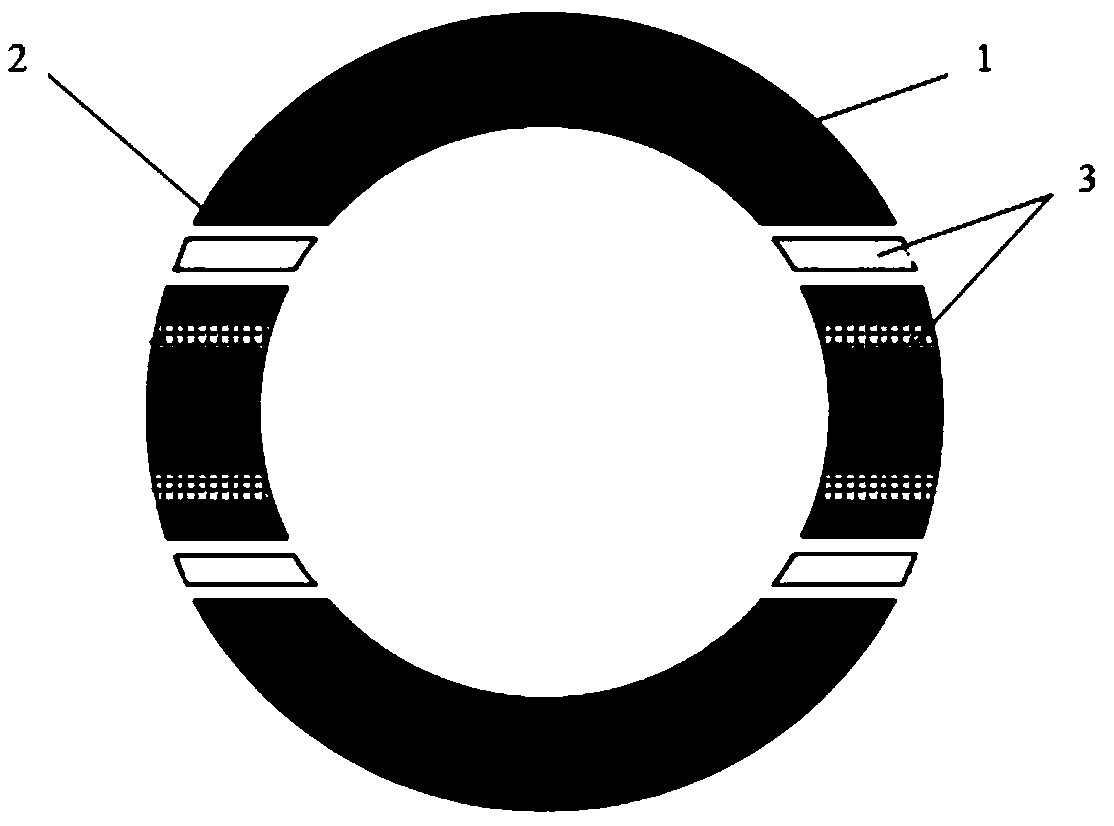

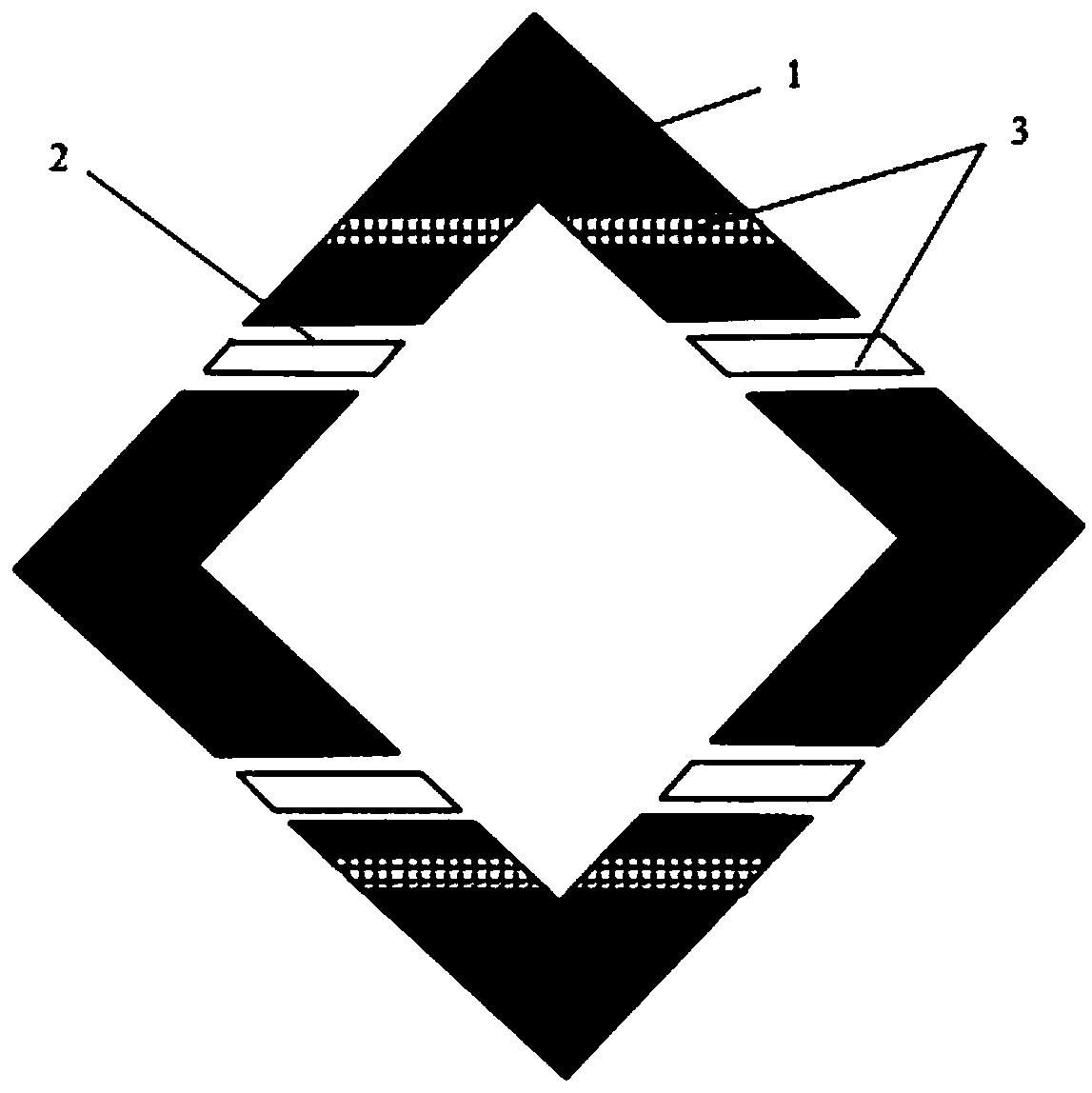

[0026] In Embodiment 1, two groups of four magnetic resistors on opposite sides of the flux guide 1 form two Wheatstone bridges respectively. The two Wheatstone bridges have the same structure, the resistance in the gap where the magneto-sensitive resistor is placed on one side is the first magneto-resistance resistor R1, and the other resistor is the second magneto-resistance resistor R2; the resistance in the gap where the magneto-sensitive resistor is placed on the other side is The third magnetoresistive resistor R3 and the other resistor is the fourth magnetoresistive resistor R4.

[0027] like Figure 5 As shown, one end of the first reluctance resistor R1 is connected to one end of the second reluctance resistor R2 and then connected to the VCC input power supply; one end of the third reluctance resistor R3 is connected to one end of the fourth reluctance resistor R4 and then grounded; the first The other end of the magnetoresistance resistor R1 is connected to the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com