Desulfurization device with tower interior flue gas condensing function and water balance control method

A desulfurization device and flue gas condensation technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as solid particle blockage, break the water balance of the original wet desulfurization device, and increase the slurry level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

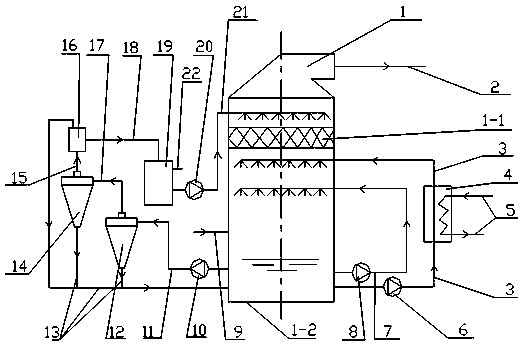

[0018] see figure 1 , a desulfurization device with flue gas condensation function in the tower, comprising a desulfurization tower 1, a cooler 4, an inlet flue 9, an outlet flue 2, a first slurry spray pipe 7, a second slurry spray pipe 3, a first A slurry spray pump 8, a second slurry spray pump 6, a cleaning water tank 19, a cleaning pump 20 and a cleaning spray pipeline 21, the desulfurization tower 1 is provided with a demister 1.1, and a slurry filter device is additionally provided. The slurry filtering device includes a primary cyclone 12, a secondary cyclone 14 and a backwash filter 16, the inlet of the primary cyclone 12 is connected to the lower part of the desulfurization tower 1 through a first connecting pipe 11, the The first connection pipe 11 is provided with a filter pump 10, the outlet of the clear liquid of the first-stage cyclone 12 is connected to the inlet of the second-stage cyclone 14 through the second connection pipe 17, and the outlet of the clear l...

Embodiment 2

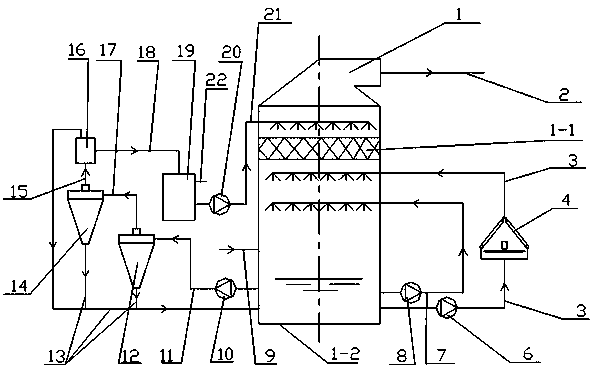

[0024] see figure 2 , The difference from Example 1 is that the cooler 4 uses a water-air heat exchanger, the inner side of the tube uses slurry (water), and the outer side of the tube uses cooling medium air.

[0025] Other technical features of embodiment 2 are the same as embodiment 1.

Embodiment 3

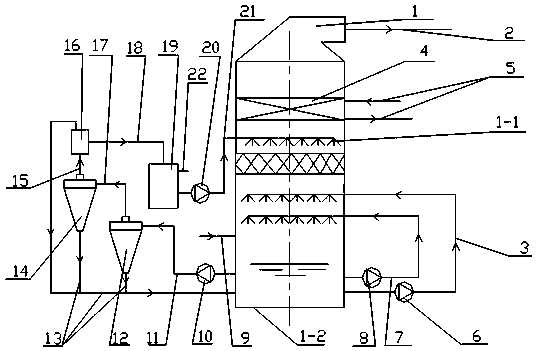

[0027] see image 3 , the difference from Example 1 and Example 2 is: 1) The flue gas is condensed by indirect heat exchange, the cooler 4 is a water-air heat exchanger, the cooling water is used in the tube, and the saturated tube is used outside the tube. Flue gas, the flue gas transfers heat to the cooling water through the heat exchange tube, and the water vapor in the flue gas is condensed on the outer wall of the heat exchange tube; 2) The cooler 4 is arranged in the desulfurization tower 1, and the second slurry spray pipe 3 and Above the demister 1.1 (rear), below the outlet flue 2 (front).

[0028] The cooling water of the cooler 4 is provided by the cooling water pipeline 5 .

[0029] Other technical features of embodiment 3 are the same as embodiment 1 and embodiment 2.

[0030] The water balance control method of embodiment 3 is also the same as embodiment 1 and embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com