Method for controlling hydrophilic modification effect inside micro-fluidic chip

A technology of microfluidic chip and control method, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem of difficult to directly characterize microfluidic chip pores and difficult to represent the hydrophilic modification of pores. The real level of the effect and other issues, to achieve the effect of stable results, short marking time, and rapid response

Active Publication Date: 2018-11-02

BEIJING UNIV OF CHEM TECH

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the pores of the microfluidic chip are at the micron level, the current evaluation of the hydrophilization effect is mostly based on the simulated treatment of the surface of the external material, and it is difficult to directly characterize the inside of the microfluidic chip's pores.

However, the force and structure of the inner and outer surfaces of the channel are different, and the external simulation test cannot represent the true level of the hydrophilic modification effect inside the channel.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] (1) Configuration of DB-TPE solution

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

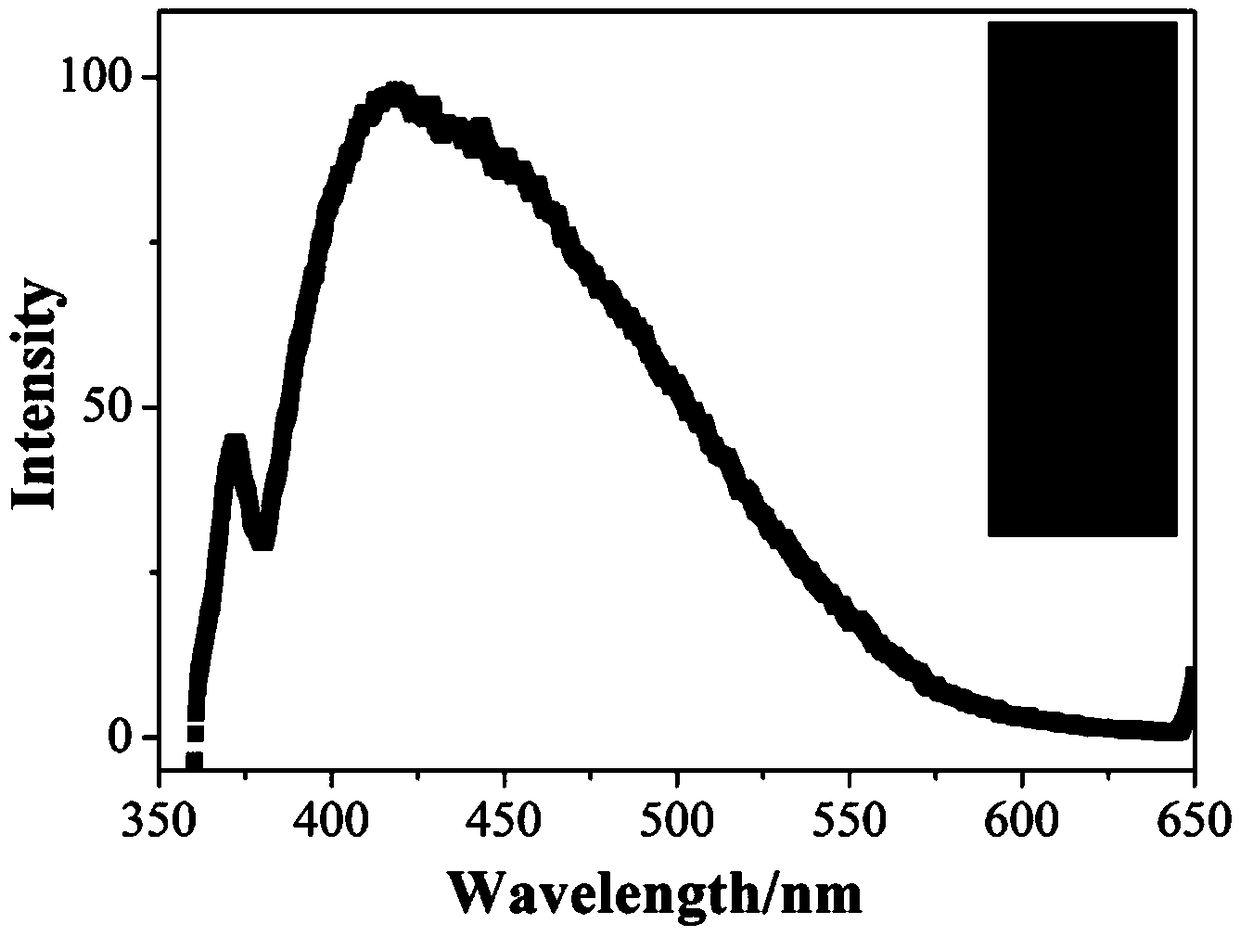

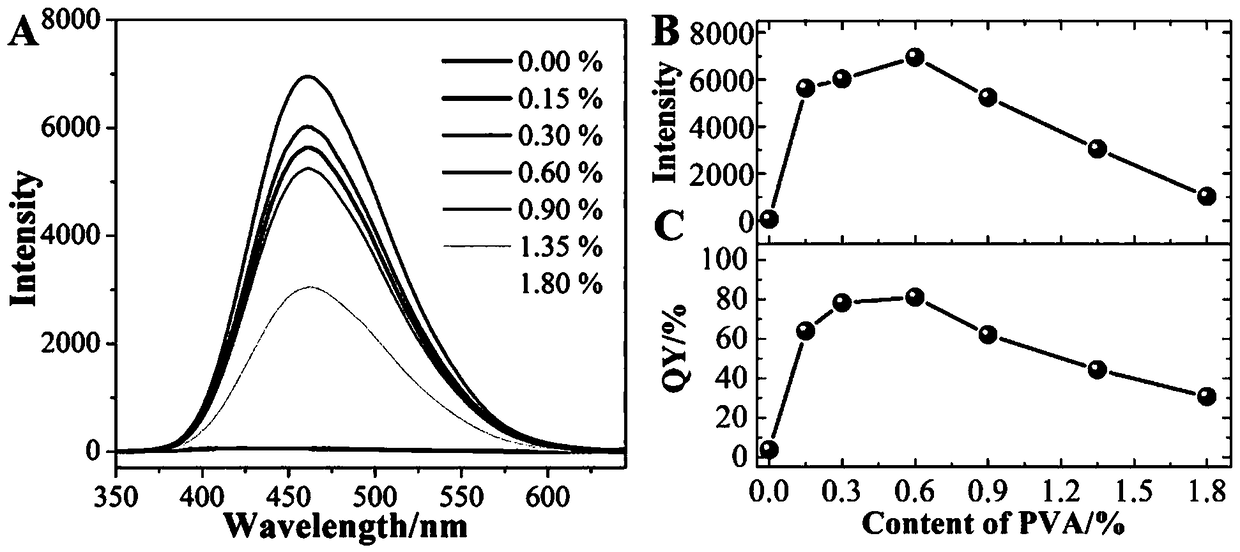

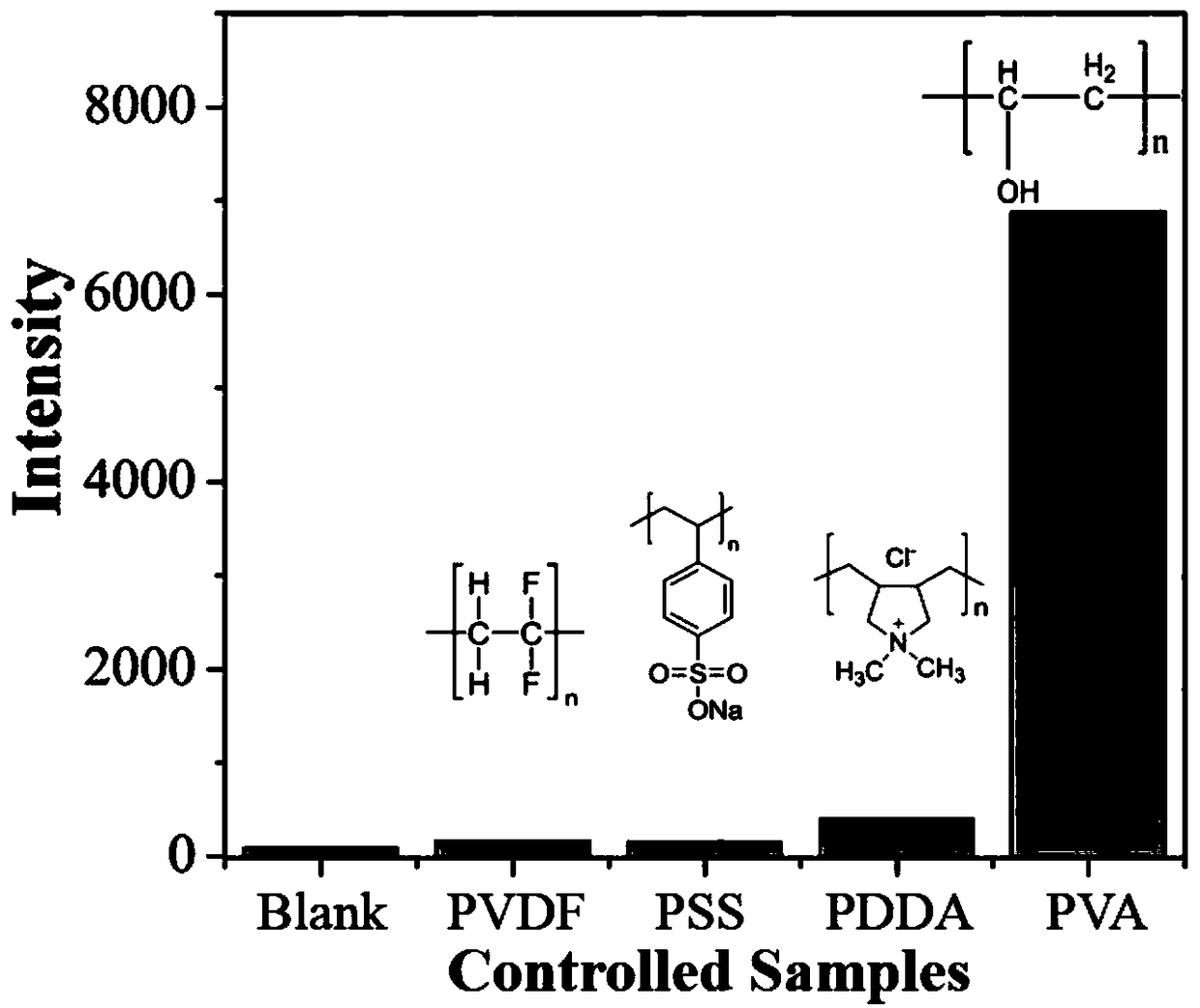

The invention provides a method for controlling the hydrophilic modification effect inside a micro-fluidic chip, and belongs to the technical field of micro-fluidic chip hydrophilic control. The method is based on the specific and selective recognition effects of aggregation induction luminescent molecules modified by two boric acid groups and PVA containing hydroxyls, the fluorescence visual imaging labeling is performed inside the micro-fluidic chip subjected to hydrophilic treatment; the inside fluorescence intensity and distribution condition can be subjected to measurement and control condition analysis through a fluorescence microscope or a laser co-focusing microscope. The method has the advantages that the in-situ visual control on the micro pore passages in the micro-fluidic chipis realized; the problem that the in-situ detection cannot be realized on the inside of the chip in the conventional measurement can be solved; the method belongs to a safe, nondestructive, fast and effective visual recognition method, and can be widely applied to the materials to realize the fast screening on the hydrophilic treatment effects.

Description

technical field [0001] The invention belongs to the technical field of hydrophilization of microfluidic chips, and in particular relates to a method for specific identification, dyeing and fluorescence imaging control of hydrophilized and modified elastic PDMS chips. Background technique [0002] Microfluidic chips have attracted attention because they can simultaneously realize sample preparation, separation, and detection in a micron-scale environment. Due to its advantages of high accuracy, good sensitivity, and less amount of reactants, it is widely used in the fields of chemistry, biology, and the environment. Among them, polydimethylsiloxane (PDMS) is due to its good optical transparency, simple preparation, and excellent elasticity. And other characteristics have become the main production materials of microfluidic chips. In order to play the important role of PDMS microfluidic chip in the sample reaction system, it is of great significance to hydrophilize its surfac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01L3/00

CPCB01L3/502707

Inventor 吕超田锐段雪

Owner BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com