Thermal regeneration method of silicate inorganic coating wet state waste sand

A silicate and heat regeneration technology, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of waste of resources, difficulty in regeneration and reuse of silicate waste sand, etc. , to achieve good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

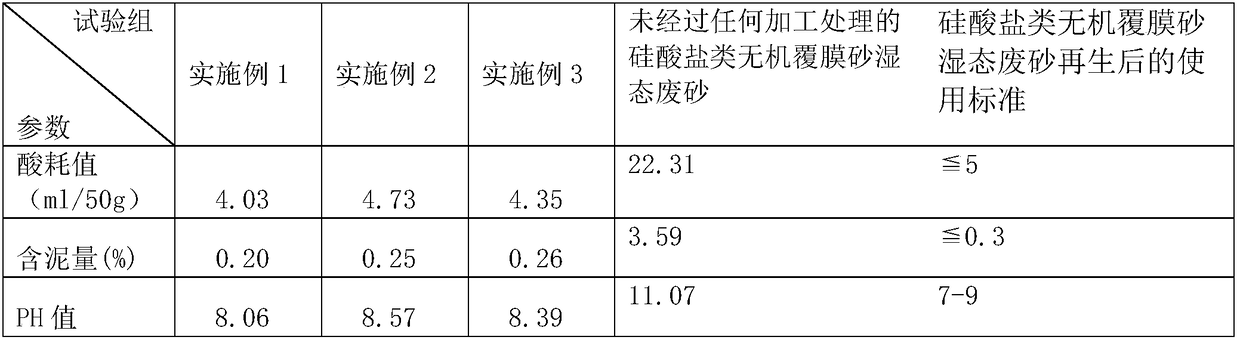

Embodiment 1

[0021] A method for thermally regenerating silicate-based inorganic film-coated wet waste sand, comprising the following steps:

[0022] (1) Sieve the waste sand after crushing, so that the metal scrap content in the waste sand is below 0.15%, and the waste sand is air-selected to remove dust, so that the fine powder content in the waste sand is below 5%; The screened waste sand is milled, and the milling time is 45s; after the milling process, a spiral scrubbing machine is used to carry out water separation and dust removal treatment on the waste sand.

[0023] (2) Put the waste sand processed through step (1) into the roasting furnace, control the particle size of the waste sand and the flow rate added, control the particle size of the waste sand less than 6 mesh, and control the flow rate of the waste sand at 35Kg / min; the temperature in the roasting zone of the roasting furnace is controlled at 450°C, and the waste sand reaches the bottom of the furnace and is kept warm f...

Embodiment 2

[0026] A method for thermally regenerating silicate-based inorganic film-coated wet waste sand, comprising the following steps:

[0027] (1) Sieve the waste sand after crushing, so that the metal scrap content in the waste sand is below 0.15%, and the waste sand is air-selected to remove dust, so that the fine powder content in the waste sand is below 5%; The screened waste sand is milled, and the time for the milling process is 20s; after the milling process, a spiral scrubbing machine is used to carry out water separation and dust removal treatment on the waste sand.

[0028] (2) Put the waste sand processed through step (1) into the roasting furnace, control the particle size of the waste sand and the flow rate added, control the particle size of the waste sand less than 6 mesh, and control the flow rate of the waste sand at 50Kg / min; the temperature in the roasting area of the roasting furnace is controlled at 480°C, and the waste sand reaches the bottom of the furnace ...

Embodiment 3

[0031] A method for thermally regenerating silicate-based inorganic film-coated wet waste sand, comprising the following steps:

[0032] (1) Sieve the waste sand after crushing, so that the metal scrap content in the waste sand is below 0.15%, and the waste sand is air-selected to remove dust, so that the fine powder content in the waste sand is below 5%; The screened waste sand is milled, and the milling time is 60s; after the milling process, a spiral scrubbing machine is used to carry out water separation and dust removal treatment on the waste sand.

[0033] (2) Put the waste sand processed through step (1) into the roasting furnace, control the particle size of the waste sand and the flow rate added, control the particle size of the waste sand less than 6 mesh, and control the flow rate of the waste sand at 38Kg / min; the temperature in the roasting zone of the roasting furnace is controlled at 430°C, and the waste sand reaches the bottom of the furnace and is kept warm f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com