Degradable master batch, plastic film comprising same and preparation method of plastic film

A technology for degrading masterbatch and plastic film, applied in the field of plastic processing, can solve the problems of low efficiency and slow degradation speed, and achieve the effect of high efficiency, fast degradation speed and accelerated degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

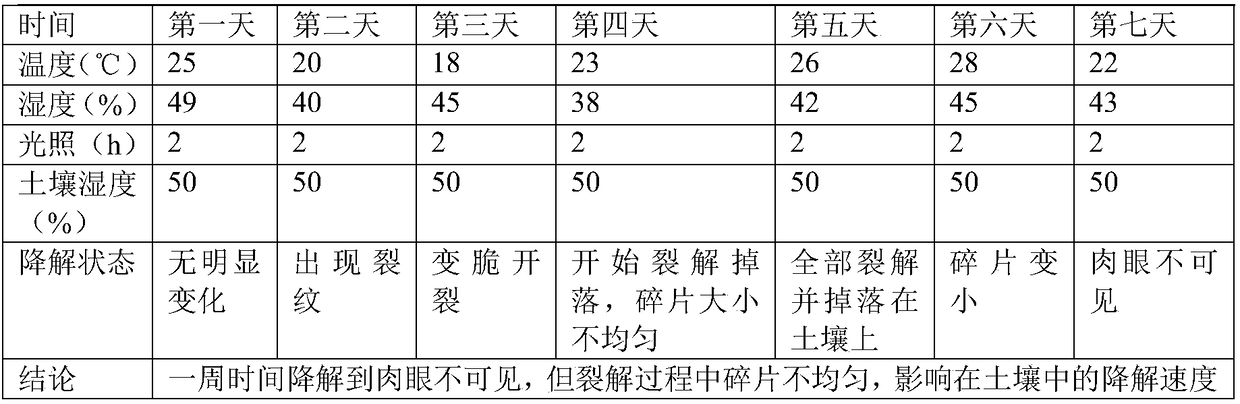

[0035] The raw materials of the degradable master batch include ferrocene, calcium carbonate, citric acid, dispersant and photosensitizer, and the components of the raw materials are: 11% of ferrocene, 76% of calcium carbonate, lemon Acid 4%, dispersant 4% and photosensitizer 5%. The percentage of each component in Example 1 is the percentage of the weight of each component to the total weight of the masterbatch. The plastic film made of the masterbatch listed in Example 1 and polyethylene with the same weight was tested, and the test results are shown in Table 1.

[0036] Table I

[0037]

[0038] It can be seen from Table 1 that although the degradation rate is faster than that of the prior art, and it can be degraded no matter under sunlight conditions (illumination) or under water vapor conditions (humidity) or under microbial conditions (soil), realizing However, it can be concluded from Table 1 that the actual cracking under the action of air and light is still not ...

Embodiment 2

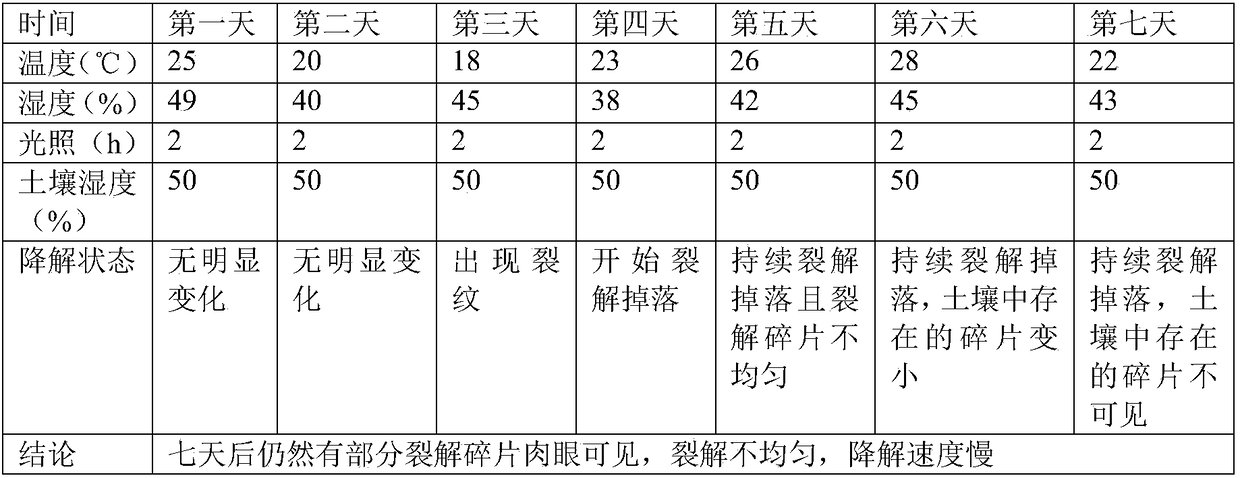

[0040] The raw materials of the degradable master batch include ferrocene, calcium carbonate, citric acid, dispersant and photosensitizer, and the components of the raw materials are: 12% of ferrocene, 72% of calcium carbonate, lemon 8% acid, 4% dispersant and 4% photosensitizer.

[0041]The plastic film made of the masterbatch listed in Example 2 and polyethylene with the same weight was tested, and the test results are shown in Table 2.

[0042] Table II

[0043]

[0044] It can be seen from Table 2 that the cracking is still slow under light and air conditions, and finally although it can be degraded simultaneously under various conditions, the degradation time is long and the efficiency is low, resulting in poor degradation effect.

Embodiment 3

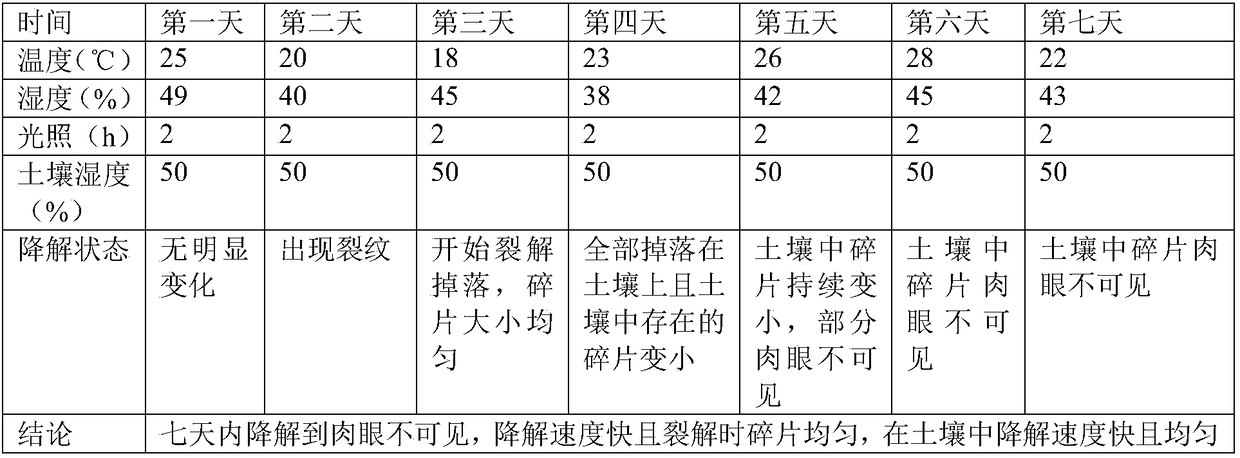

[0046] The raw materials of the degradable master batch include ferrocene, calcium carbonate, citric acid, dispersant and photosensitizer, and the components of the raw materials are: 10% of ferrocene, 74% of calcium carbonate, lemon Acid 6%, dispersant 4% and photosensitizer 6%.

[0047] The plastic film made of the masterbatch listed in Example 3 and polyethylene with the same weight was tested, and the test results are shown in Table 3.

[0048] Table three

[0049]

[0050] It can be seen from Table 3 that the plastic film formed by adding the masterbatch in Example 3 to polyethylene is the most stable and rapid during cracking, and the cracked fragments are uniform in size, and the degradation time in soil is short, fast and efficient.

[0051] A plastic film containing degradable master batches, the raw material of the plastic film includes a compound of polyethylene and degradable master batches, and the weight ratio of the polyethylene and the degradable master bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com