Modified polypropylene carbonate material and preparation method thereof

A polypropylene carbonate modification technology, applied in the field of modified polypropylene carbonate materials and its preparation, can solve the problems of low thermal stability and mechanical properties, limit molding processing and application cycle, etc., and achieve enhanced mechanical properties , Avoid mechanical property attenuation, inhibit degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

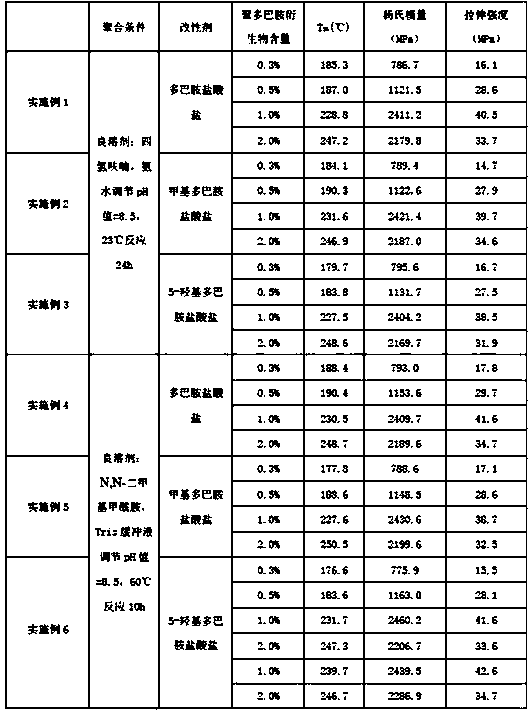

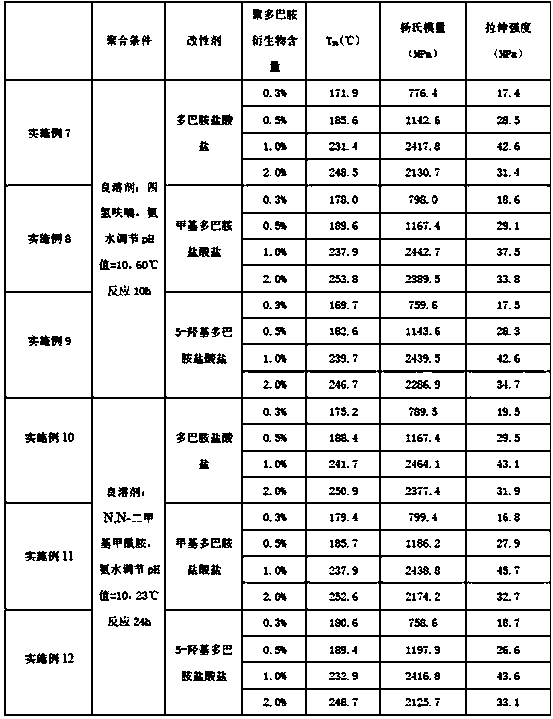

Embodiment 1

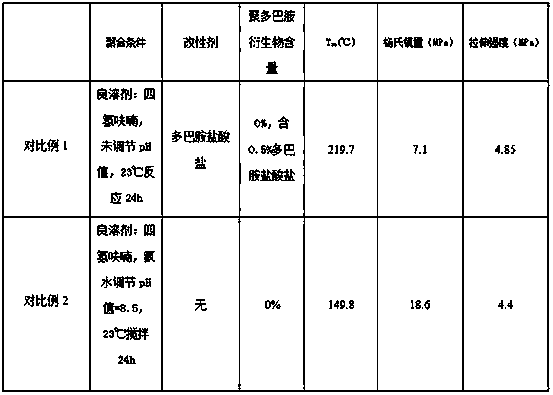

[0043] Embodiment 1: the preparation of modified polypropylene carbonate

[0044] S1: Mix 150mL tetrahydrofuran and 30mL deionized water evenly to prepare a mixed solvent;

[0045] S2: Add 3 mL of ammonia water dropwise to the mixed solvent obtained in S1, and adjust the pH value to 8.5;

[0046] S3: Make 4 parallel groups, add 0.045g, 0.075g, 0.15g and 0.3g dopamine hydrochloride to the mixed solvent obtained in S2 respectively, the mass concentration of the prepared dopamine hydrochloride is 0.25mg / mL, 0.42mg / mL, 0.83mg / mL and 1.67mg / mL;

[0047] S4: exposing the solution obtained in S3 to air conditions, and stirring at 23° C. for 24 hours to obtain a polydopamine derivative solution;

[0048] S5: Weigh 15g of polypropylene carbonate and dissolve it in 500mL of tetrahydrofuran;

[0049] S6: under stirring conditions, drop the polydopamine derivative solution obtained in S4 into the solution of S5, and stir to make the two components evenly mixed;

[0050] S7: Pour the m...

Embodiment 2

[0053] Embodiment 2: In step S3, methyl dopamine hydrochloride is used instead of dopamine hydrochloride, and the rest are the same as in embodiment 1.

Embodiment 3

[0054] Embodiment 3: In step S3, replace dopamine hydrochloride with 5-hydroxydopamine hydrochloride, and the rest are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com