Novel temperable double-silver low-emissivity energy-saving glass

An energy-saving glass and low-radiation technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of small color cast on the front and side, large color cast of film surface strength, and high film surface strength , to achieve the effect of small color cast, small color deviation and high film surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

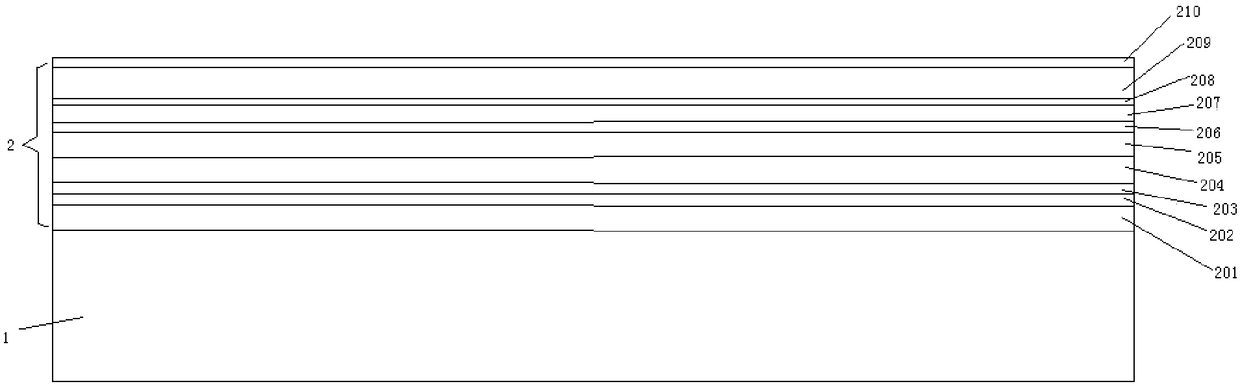

[0032] Toughened double-silver low-radiation energy-saving glass, on the original glass, adopts off-line magnetron sputtering coating technology, and sequentially coats 35nm silicon nitride layer, 10nm zinc oxide layer, 4nm silver layer, and 10nm ceramic zinc oxide layer under high vacuum background Aluminum layer, 25nm silicon nitride layer, 35nm zinc tin oxide layer, 8nm zinc oxide layer, 15nm silver layer, 2nm nickel chromium layer, 60nm silicon nitride layer and 8nm graphite layer. The above coating layer structures are arranged in sequence.

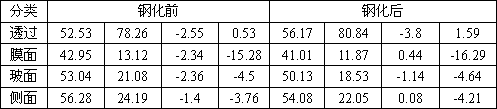

[0033] The color parameter of embodiment 1 product:

[0034]

[0035] The specific performance of the product in Example 1 is as follows, product structure (6GM+12A+6):

[0036]

Embodiment 2

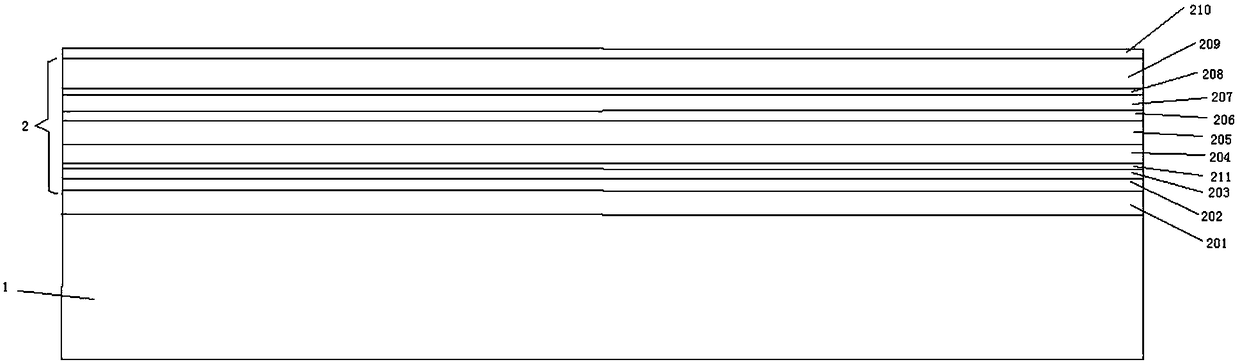

[0038] Toughened double-silver low-radiation energy-saving glass, on the original glass, sequentially plated 50nm silicon nitride layer, 4nm zinc oxide layer, 8nm silver layer, 40nm silicon nitride layer, 20nm zinc tin oxide layer, 2nm zinc oxide layer, 20nm silver layer Layer, 5nm nickel-chromium layer, 40nm silicon nitride layer and 3nm graphite layer, arrange the above-mentioned coating layer structure in sequence.

[0039] The color parameter of embodiment 2 products:

[0040]

[0041] The specific performance of the product in Example 2 is as follows, product structure (6GM+12A+6):

[0042]

Embodiment 3

[0044] Toughened double-silver low-radiation energy-saving glass, on the original glass, adopts off-line magnetron sputtering coating technology, and sequentially coats a 30nm silicon nitride layer, a 15nm zinc oxide layer, a 2nm silver layer, and a 20nm silicon nitride layer under a high vacuum background layer, 40nm zinc tin oxide layer, 10nm zinc oxide layer, 10nm silver layer, 1nm nickel-chromium layer, 70nm silicon nitride layer and 10nm graphite layer, and arrange the above coating layer structure in sequence.

[0045] The color parameter of embodiment 3 products:

[0046]

[0047] The specific performance of the product in Example 3 is as follows, product structure (6GM+12A+6):

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com