Fixed structural member, rotary lifting device and semiconductor processing equipment

A fixed structure, rotating lifting technology, applied in the field of magnetron sputtering, can solve the problems of difficult installation and disassembly, damage to fragile materials, and heavy weight, so as to improve the speed of installation and disassembly, reduce the difficulty of installation and disassembly, and reduce the risk of damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

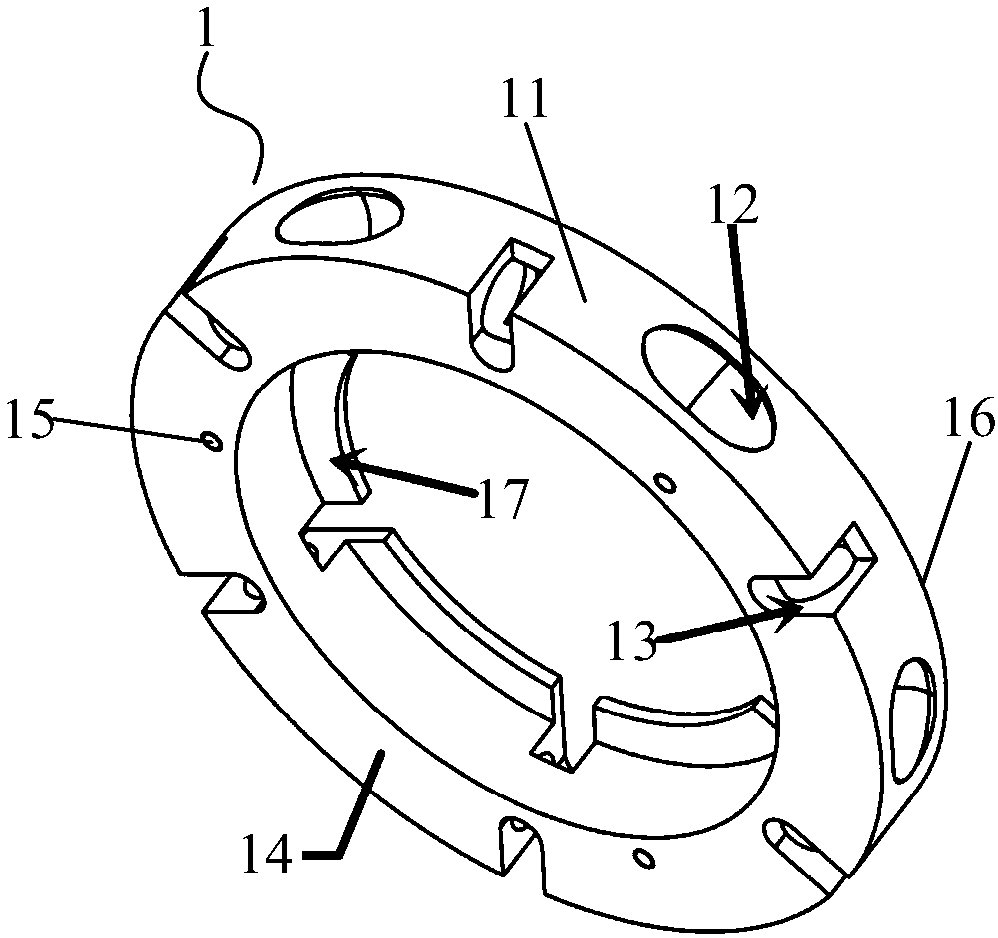

[0045] This embodiment provides a fixed structure, such as Figure 3-Figure 9 As shown, it includes a first ring structure 1, a second ring structure 2 and a connector 3, wherein the first ring structure 1 and the second ring structure 2 fit together to form a ring structure; the connector 3 is movably arranged on the first ring In structure 1, the second ring structure 2 can rotate relative to the first ring structure 1 to push the connecting member 3 to swing within a certain angle range, so as to fix or release the fixed object.

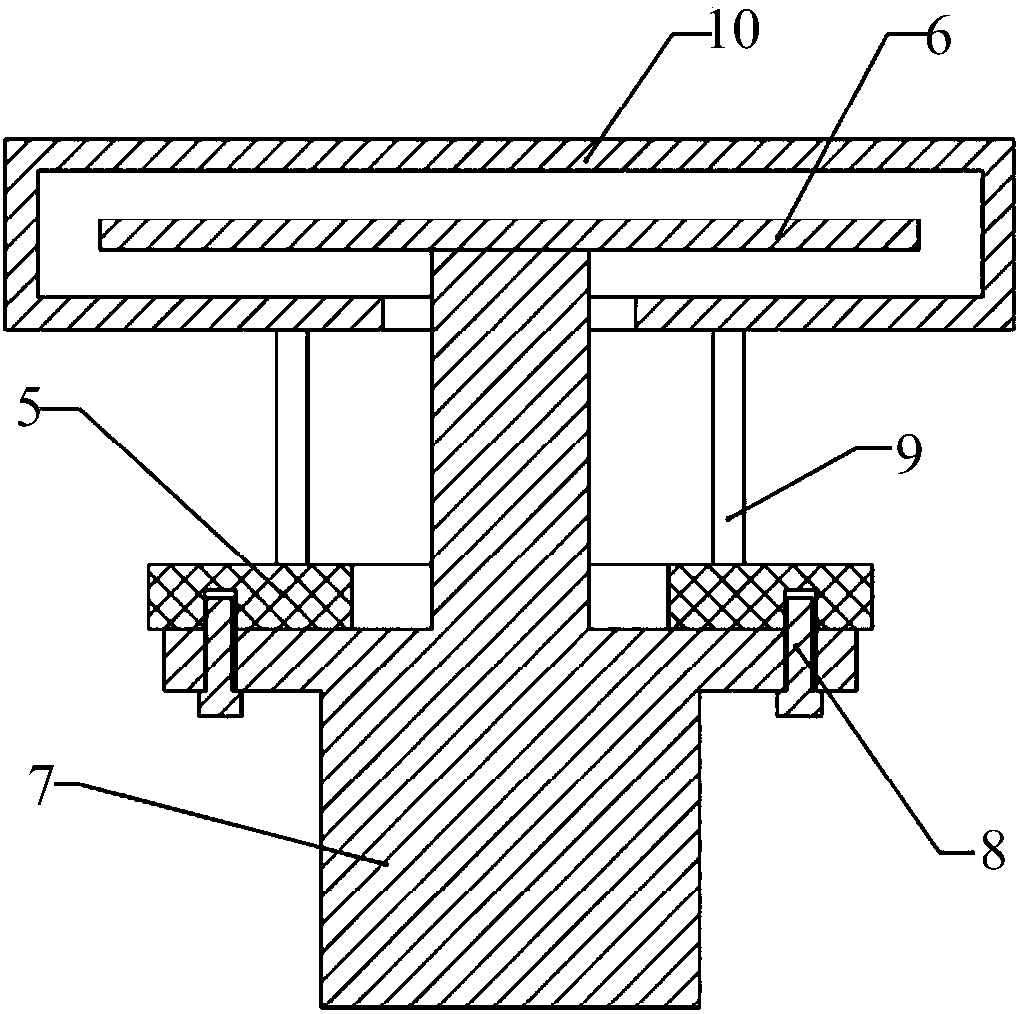

[0046] In this embodiment, the fixing structure is used to be installed on the flange 5 suspended on the bottom of the chamber 4, so as to fix or release the rotating lifting mechanism 7 that drives the tray 6 to rotate and lift. Swinging within a certain angle range can realize fixing or releasing fixing of the rotating lifting mechanism 7 . The fixed structural part can form a good load on the rotating lifting mechanism 7 before the connecting ...

Embodiment 2

[0062] This embodiment provides a rotary lifting device, such as Figure 10 and Figure 11 As shown, it includes the rotating lifting mechanism 7 and the flange 5, and also includes the fixing structure 19 in Embodiment 1. The fixing structure 19 is arranged on the flange 5 for fixing and releasing the rotating lifting mechanism 7.

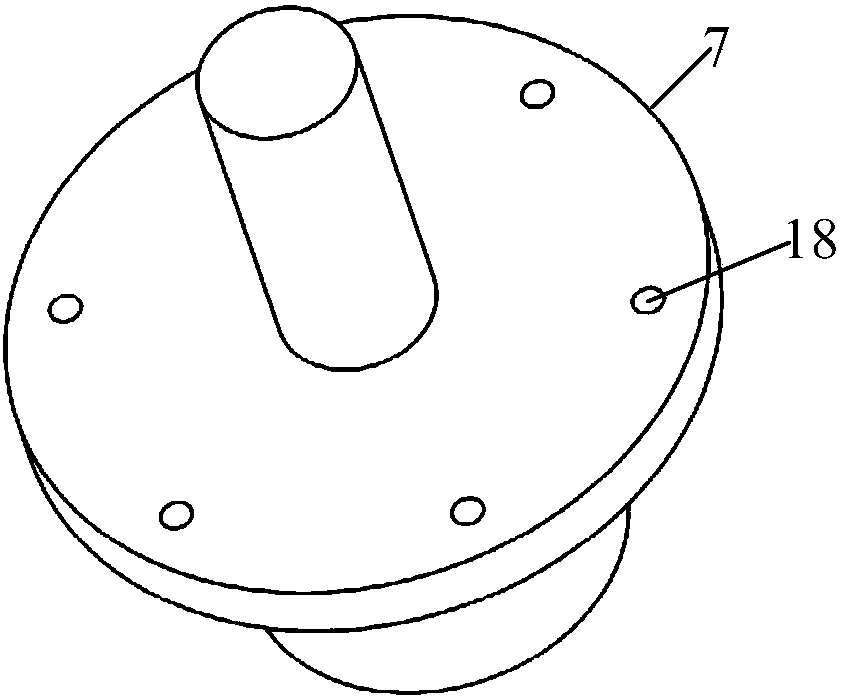

[0063] Among them, such as Figure 11 As shown, a plurality of fifth through holes 71 are provided on the edge of the end of the rotary lifting mechanism 7 for bonding with the lower surface of the flange 5 facing away from the bottom of the chamber 4, and the fifth through holes 71 are formed at the end. The edge is not closed; the fifth through hole 71 corresponds to the position of the second through hole 13, and when the first fixing rod 32 is parallel to the axis of the ring structure, it passes through the second through hole 13 and the fifth through hole 71, To fix the rotating lifting mechanism 7. When the first fixing rod 32 forms a se...

Embodiment 3

[0067] This embodiment provides a semiconductor processing equipment, including a chamber, the bottom of the chamber is provided with a tray, and also includes the rotating lifting device in Embodiment 2, the flange of the rotating lifting device is fixed on the bottom of the chamber through a support rod, and rotates The rotary lifting mechanism of the lifting device is fixed on the flange through the fixed structure, and the shaft of the rotary lifting mechanism used to drive the tray to rotate and lift passes through the inner ring of the fixed structure and enters the chamber, and contacts with the tray.

[0068] By adopting the rotary lifting device in Embodiment 2, the installation and disassembly speed of the semiconductor processing equipment is improved, thereby improving the maintenance efficiency of the semiconductor processing equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com