Frequency converter

A frequency converter and frequency conversion circuit technology, applied in the field of frequency converters, can solve the problems of power performance decline, affecting equipment, property loss, etc., to prevent the occurrence of oxidation reactions, reduce the incidence of failures, and reduce the effects of fire hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

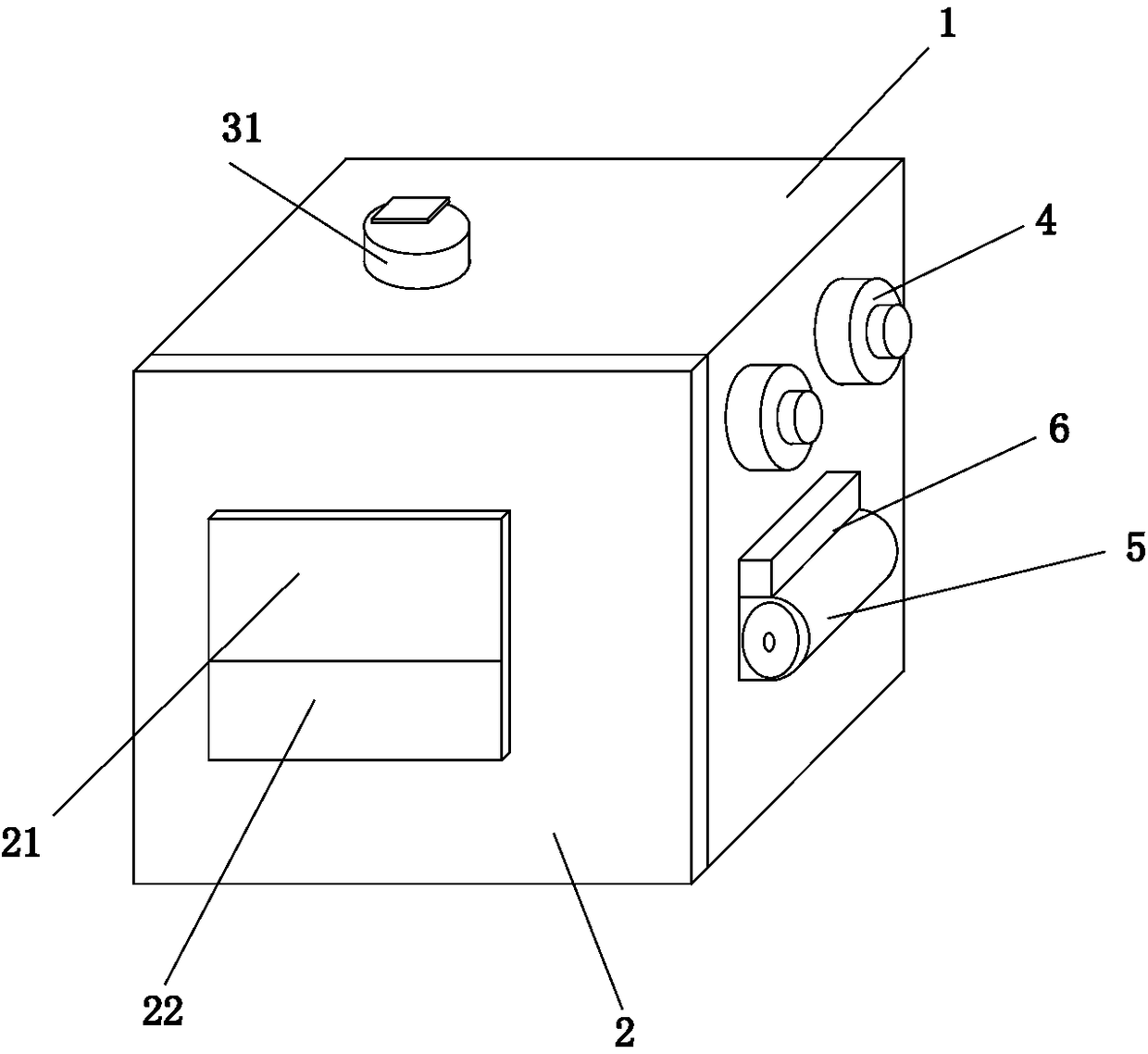

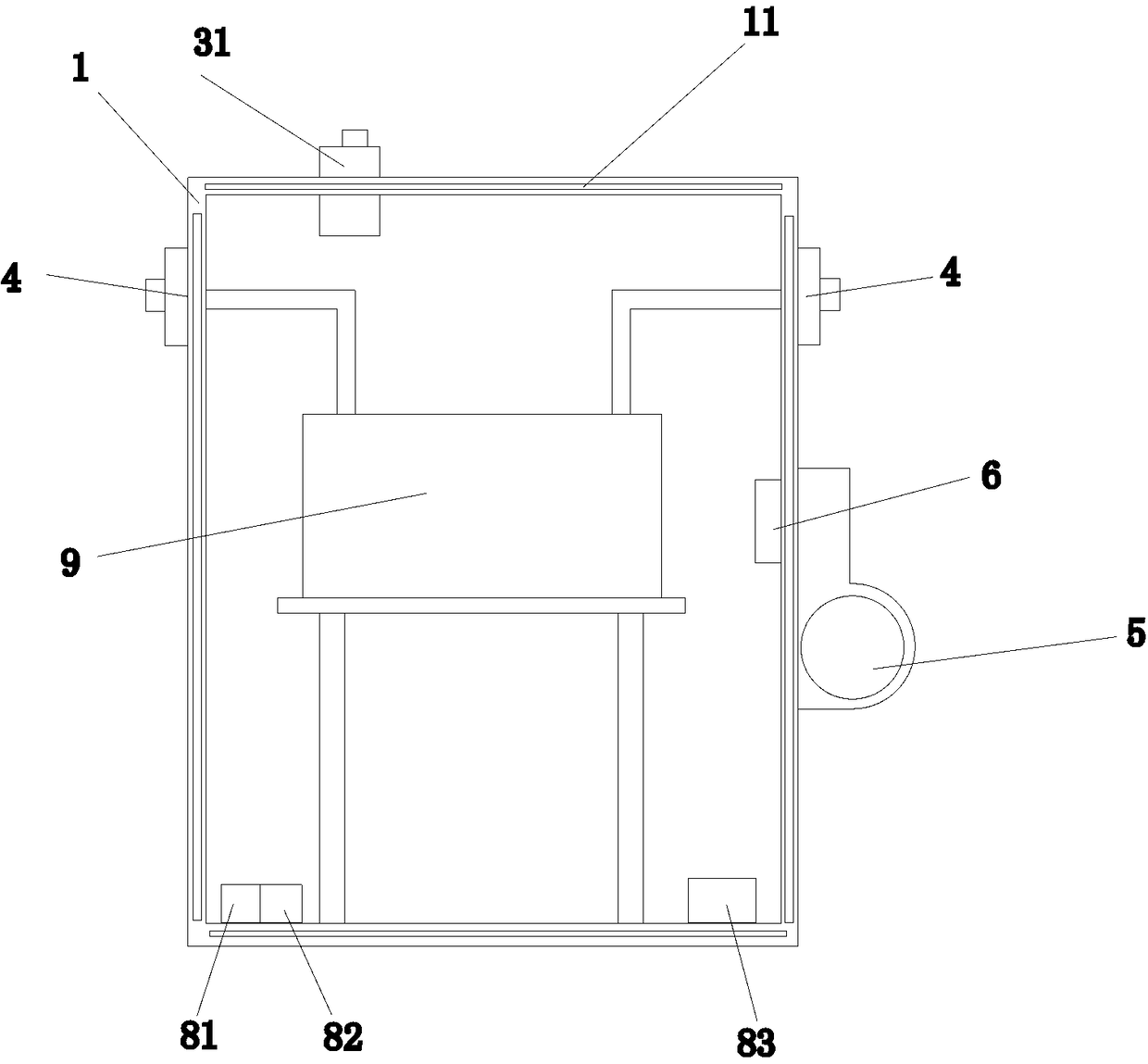

[0015] Example 1: Such as Figure 1 to Figure 2 As shown, the frequency converter includes a frequency conversion circuit 9 and a cabinet 1, and the surface of the cabinet 1 is coated with a thermally conductive barrier. The cabinet 1 includes a cabinet door 2. The cabinet door 2 is in sealed contact with the cabinet 1, a plurality of electromagnets 11 are provided on the cabinet 1, and the cabinet door 2 is provided There are patches matched with the electromagnet 11, and the cabinet body 1 and the cabinet door 2 are respectively provided with sealing rubber strips. The cabinet door 2 is provided with a display 21 and a controller 22 connected to the frequency conversion circuit 9. The cabinet 1 is provided with a vacuum pump 31 and a gas storage tank 5, the gas storage tank 5 stores compressed nitrogen gas, and the gas storage tank 5 is provided with a flow pump 6, the flow pump 6 is connected to the cabinet 1 and the gas tank 5 is detachable. One section of the vacuum pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com