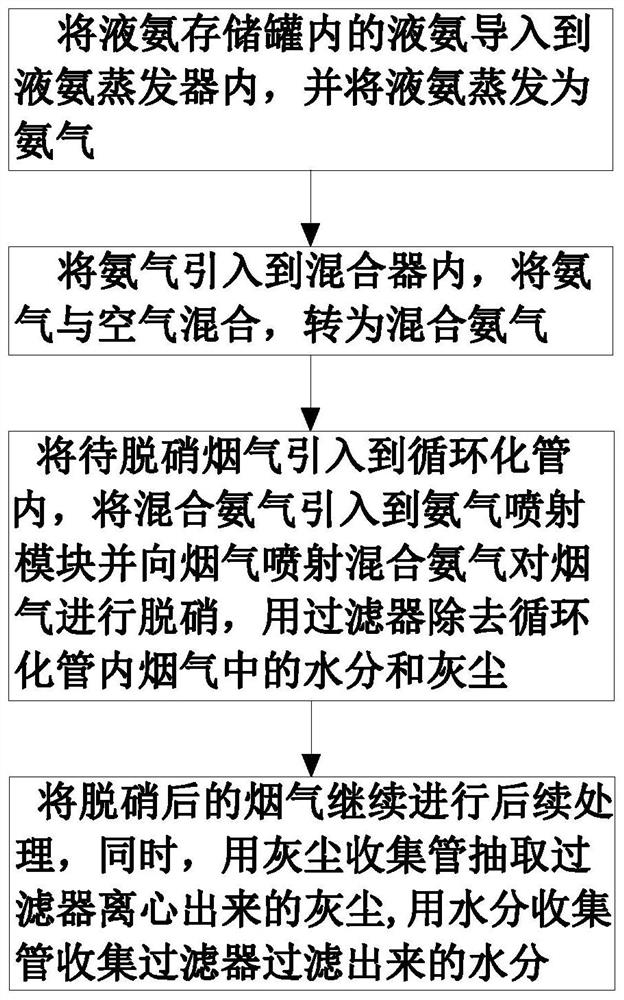

A kind of SCR industrial flue gas denitrification method

An industrial flue gas and denitrification technology, applied in the field of flue gas denitrification, can solve the problems of easy generation of swirl layer, unfavorable flue gas denitrification, uneven mixing of flue gas and ammonia gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

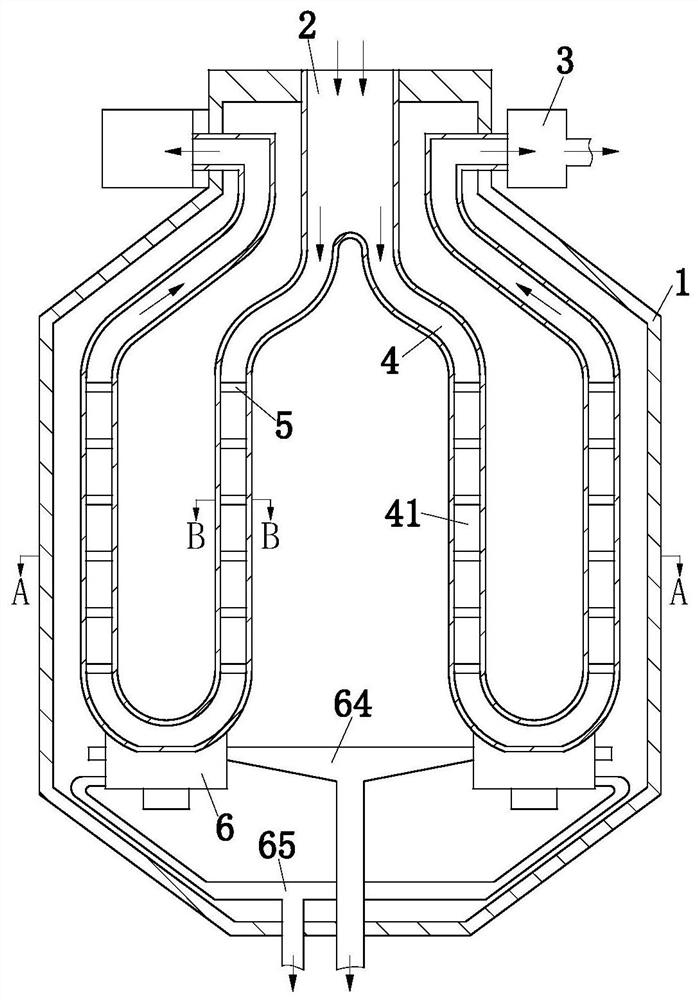

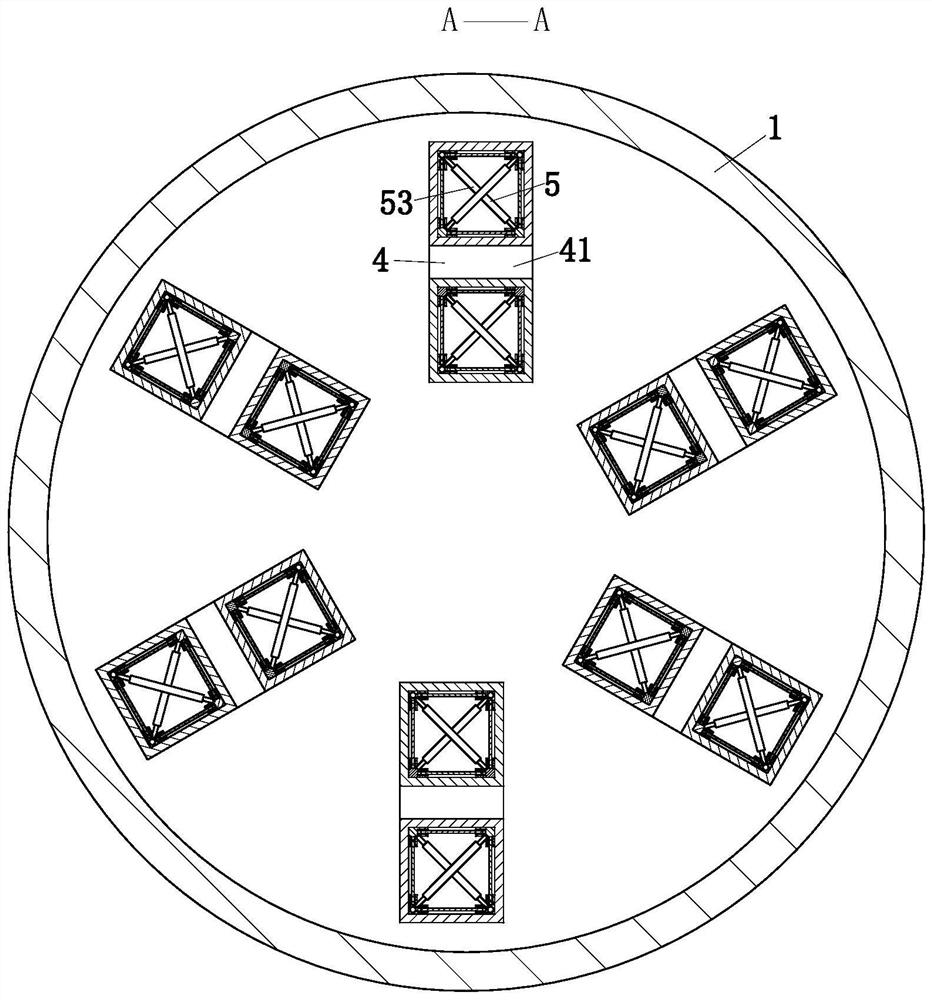

[0040] As an embodiment of the present invention, the ammonia injection module 5 includes a fixed frame 51, a shower 53 and a catalytic plate 54; the fixed frame 51 is a right-angled V-shaped, and the fixed frame 51 includes a fixed frame one 52 and Fixed frame two 522; the fixed frame one 52 is located at two adjacent corners of the sub-circulation pipe 41, the fixed frame two 522 is located at the other two adjacent corners of the sub-circulation pipe 41, and the diagonal fixed frame one 52 and the fixed frame two 522 are located on the same horizontal plane, and the first fixed frame 52 is provided with a spray interface 521; the sprinklers 53 are arranged on the diagonal fixed frame one 52 and the second fixed frame 522, and the sprayers 53 are equidistantly intersected. One end of the shower 53 communicates with the spray interface 521; the catalytic plate 54 is located between the adjacent fixing frames 51, the catalytic plate 54 is in the shape of a block, and a catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com