Special scroll machining machine tool and machining method thereof

A special machine tool and scroll technology, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of processing noodle-shaped defects, complex helical shape, and reduce processing accuracy, and achieve accurate movement and improve production. The effect of precision and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

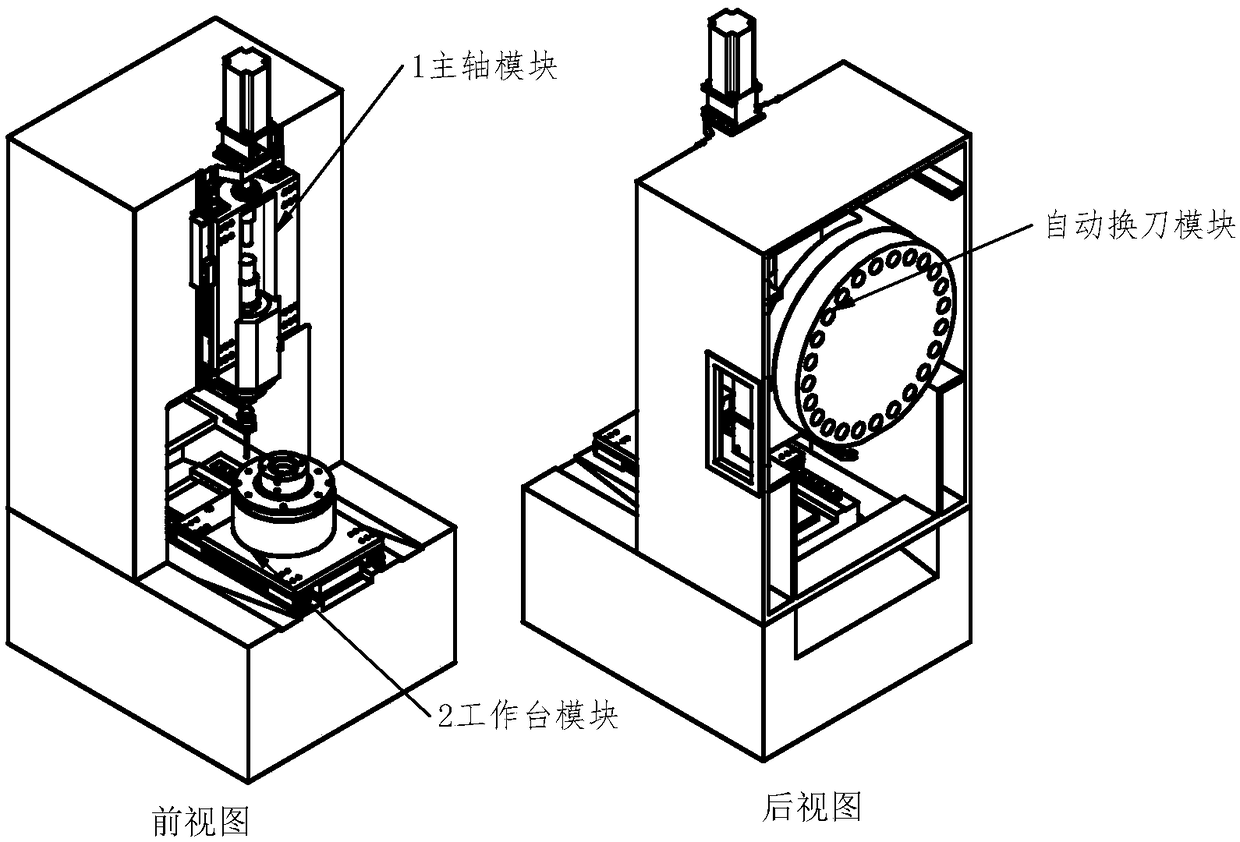

[0040] The special machine tool of the present invention is composed of a spindle module 1 , a workbench module 2 , an automatic tool change module 3 and a lubricating and cooling system 4 .

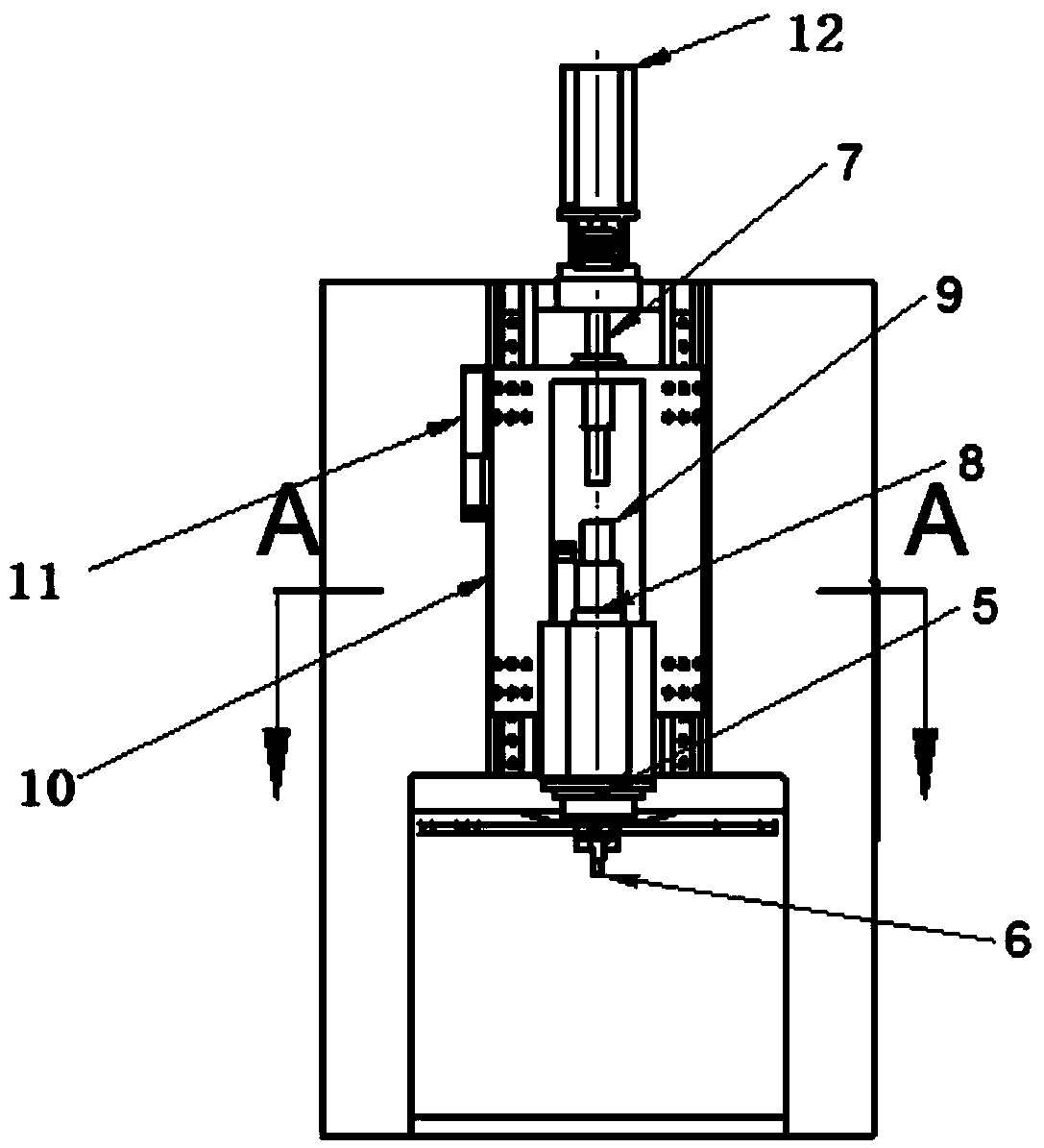

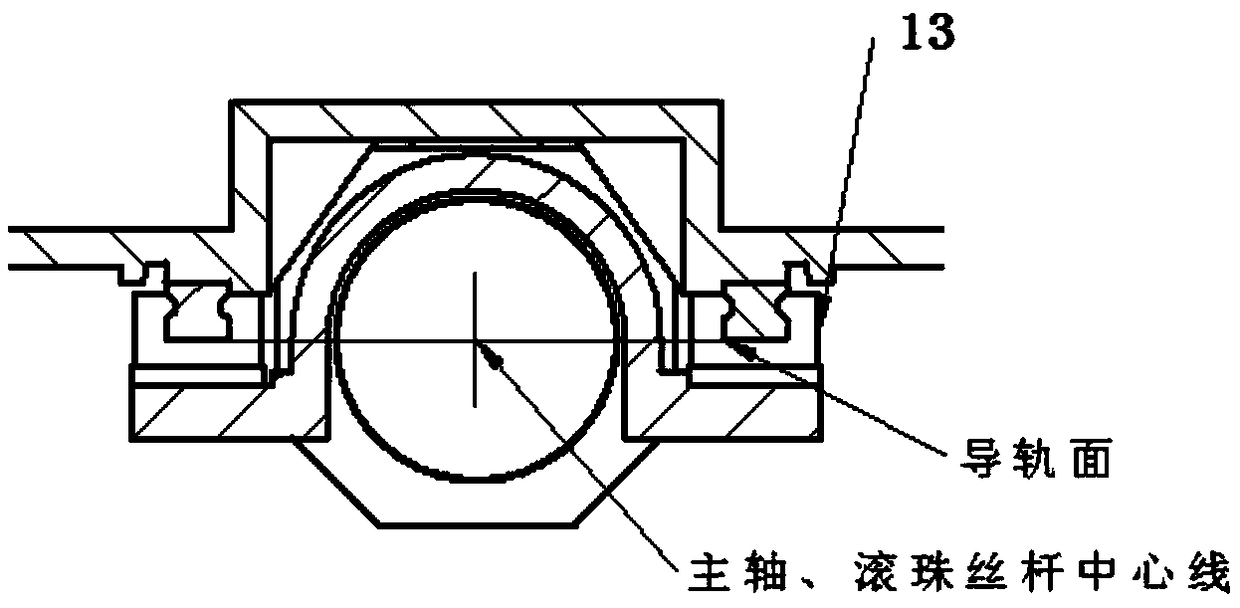

[0041] Among them, the spindle module such as figure 2 and image 3 As shown; the main shaft adopts the electric main shaft 5, configures the rotary water inlet 9 to realize the central water outlet function, and configures the knife cylinder 8 to realize the function of cutting and loading when the tool is changed automatically; the milling cutter 6 is installed on the head of the main shaft and adopts the HSK50E knife The handle structure is connected; the Z-axis slide table 10 has the main shaft installation hole coaxial with the ball screw pair 7 installation holes, and the screw transmission force is coaxial with the main shaft force, which improves the stability of the slide table movement; the Z-axis slide table 10 has the main shaft The center line of the installation hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com