A control device and method for driving space manipulator joints

A technology of a space manipulator and a control device, applied in the field of control, can solve the problems of rapid movement of the space manipulator, unsatisfactory precision, inability to select a suitable motor, limited installation space, etc. The effect of reducing and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

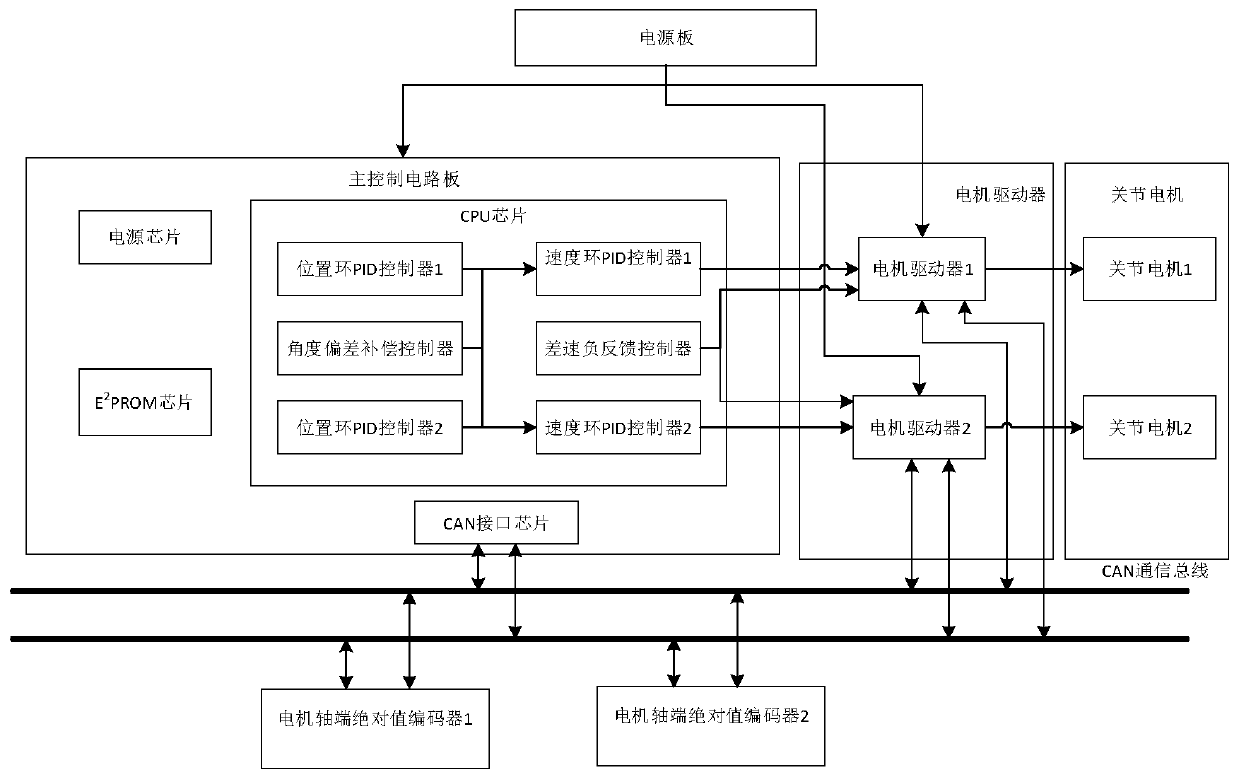

[0051] This embodiment discloses a control device for joint drive of a space manipulator, such as figure 1 shown, including:

[0052] Main control circuit board, motor driver, joint motor, absolute value encoder at motor shaft end and power board.

[0053] Among them, the absolute value encoder of the motor shaft end is installed at the end of the joint motor shaft end, and the absolute value of the rotation angle of the motor shaft is encoded and sent to the main control circuit board;

[0054] The motor driver is electrically connected to the main control circuit board and the joint motor, executes the control instructions of the main control circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com