Integral-molding manufacturing method of carbon-fiber composite made oil tanks for small and middle sized unmanned aerial vehicle

A technology of mechanical carbon fiber and composite materials, which is applied in the field of integral molding and manufacturing of carbon fiber composite fuel tanks for small and medium-sized UAVs. It can solve the problems of low comprehensive mechanical properties and environmental adaptability, heavy weight of composite fuel tanks, and long production cycles. Improve the scope of application, reduce production costs, and use low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

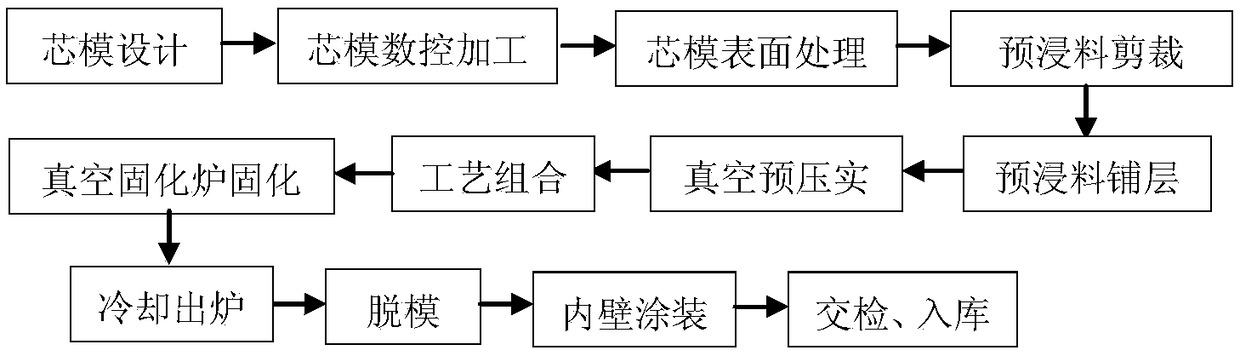

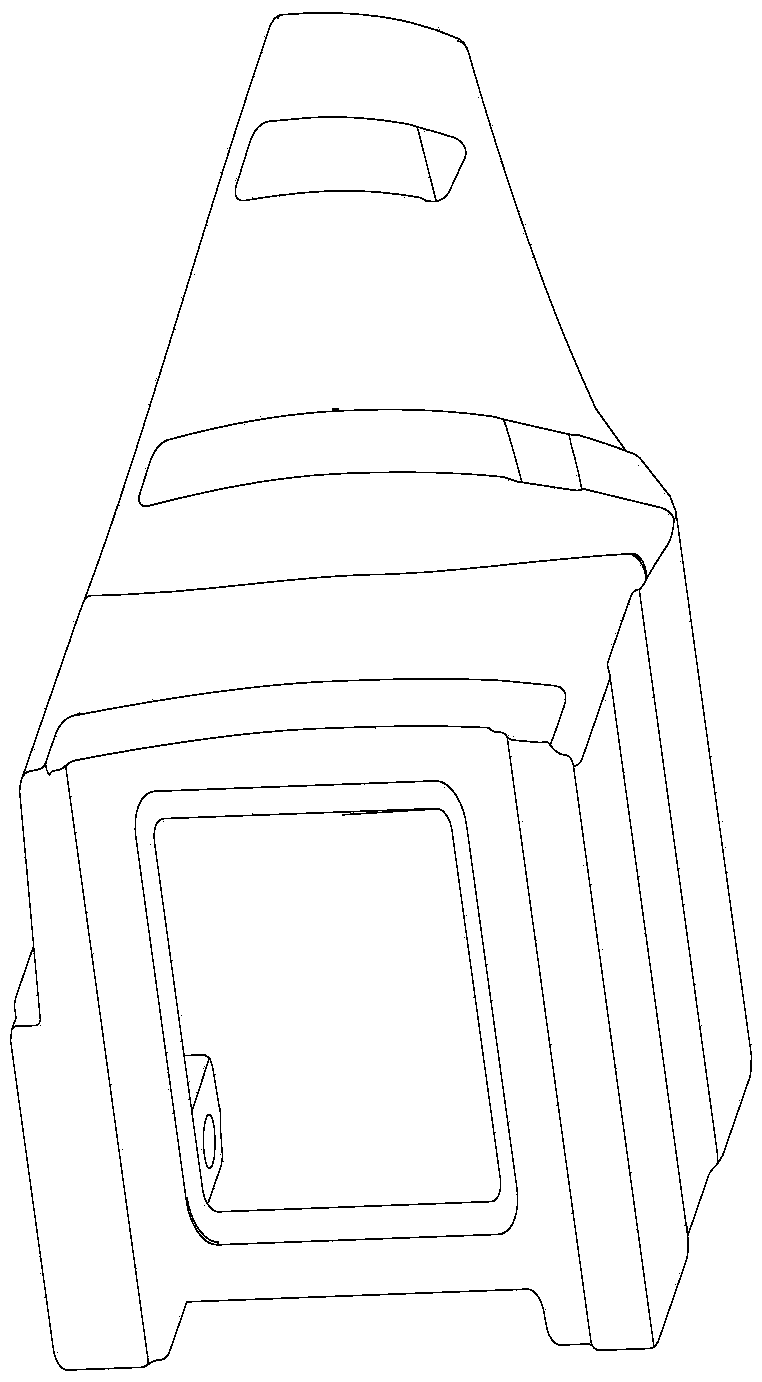

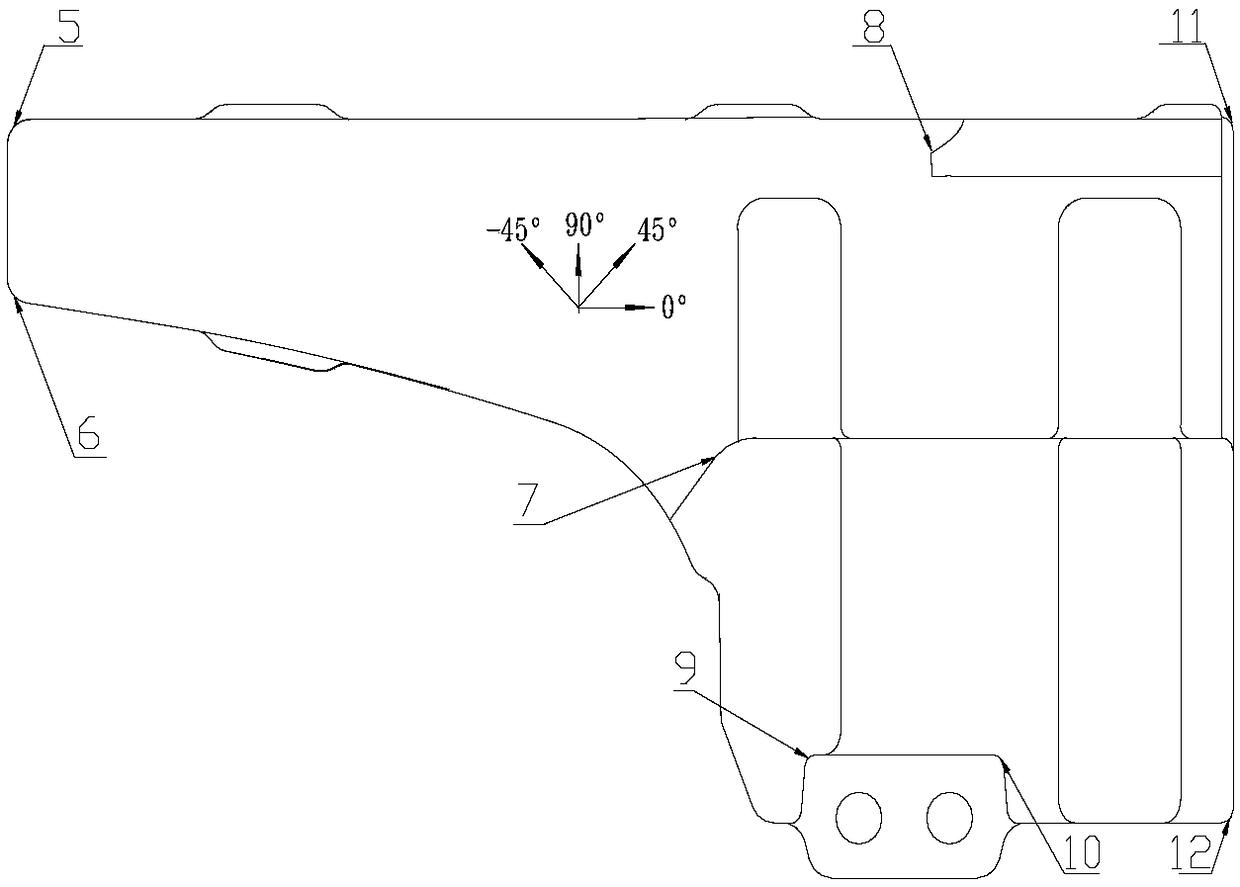

[0038] see Figure 1-Figure 6 , a small and medium-sized unmanned aerial vehicle carbon fiber composite fuel tank integral molding manufacturing method, the process includes the following steps:

[0039] Step 1, making a carbon fiber structure fuel tank core mold 1: The core mold material is a closed-cell rigid foam material with good heat resistance, a thermal expansion coefficient close to that of carbon fiber composite materials, and good compression creep resistance.

[0040] According to the physical performance parameters in the foam material specification, the foam specifications used and the foam thermal expansion, compression creep, and processing allowances under medium-temperature curing vacuum-assisted molding are determined.

[0041] Using three-dimensional modeling, the foam mandrel is processed according to the digital model, and the foam mandrel 1 is obtained; it is packaged and protected in time.

[0042] Step 2, surface treatment of the mandrel: unsealing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com