A method and device for producing ammonium metatungstate from tungsten-containing waste materials

A technology of ammonium metatungstate and tungsten waste, which is applied in the direction of chemical instruments and methods, preparation of tungsten compounds, tungsten compounds, etc. It can solve the problems of limited cobalt content of raw materials, roasting equipment, low recovery rate, etc., and achieve tungsten recovery The effect of high efficiency, improved production efficiency, and great promotion significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

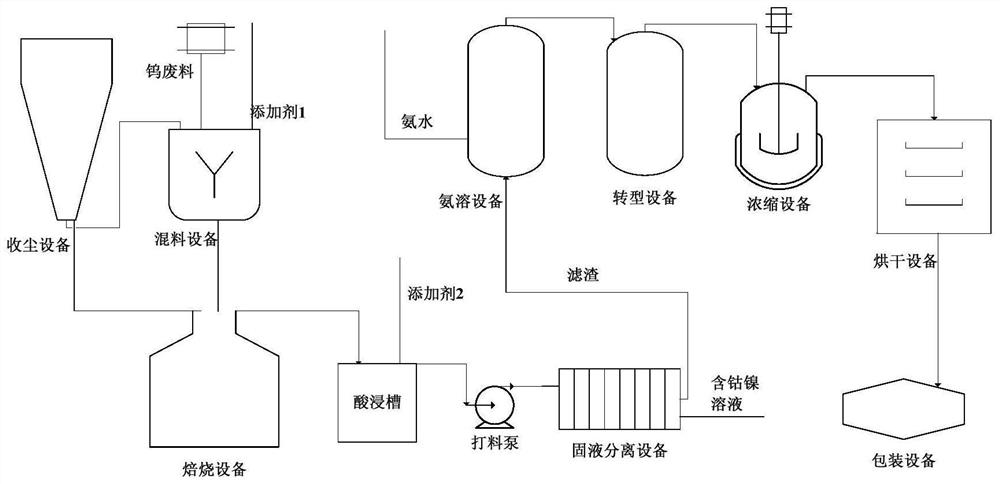

Image

Examples

Embodiment 1

[0050] The steps to produce ammonium metatungstate from tungsten-containing waste are as follows:

[0051] Step 1: Take 20g of tungsten-containing waste, add calcium carbonate, Ca / WO 3 The ratio of the amount of substance is 1.5, mix uniformly, obtain compound;

[0052] Step 2: The mixture is roasted at a roasting temperature of 750°C for a roasting time of 4 hours to obtain a roasted material;

[0053] Step 3: Add hydrochloric acid to the roasting material to react, and the addition ratio is [H + ] / WO 3 The ratio of the amount of substances is 3, the reaction temperature is 95°C, and the reaction time is 3h, to obtain a solid-liquid mixture;

[0054] Step 4: Filtrate the solid-liquid mixture, and wash the filter residue three times with heated anhydrous brine to obtain a cobalt-nickel-containing solution and filter residue tungstic acid; tungstic acid is added to ammonia water after drying, wherein the initial ammonia concentration is 150g / l, at 90°C React in a water bath...

Embodiment 2

[0057] The steps to produce ammonium metatungstate from tungsten-containing waste are as follows:

[0058] Step 1: Take 30g of tungsten-containing waste, add calcium hydroxide, Ca / WO 3 The ratio of the amount of substance is 1.8, mix uniformly, obtain compound;

[0059] Step 2: roasting the mixture, the roasting temperature is 800°C, and the roasting time is 3 hours, to obtain the roasted material;

[0060] Step 3: Add hydrochloric acid to the roasting material to react, and the addition ratio is [H + ] / WO 3 The ratio of the amount of substances is 2.5, the reaction temperature is 95°C, and the reaction time is 3h, to obtain a solid-liquid mixture;

[0061] Step 4: Filtrate the solid-liquid mixture, and wash the filter residue three times with heated anhydrous brine to obtain a cobalt-nickel-containing solution and filter residue tungstic acid; tungstic acid is added to ammonia water after drying, wherein the initial ammonia concentration is 150g / l, at 90°C React in a wate...

Embodiment 3

[0064] The steps to produce ammonium metatungstate from tungsten-containing waste are as follows:

[0065] Step 1: Take 50g of tungsten-containing waste, add calcium oxide, Ca / WO 3 The ratio of the amount of the substance is 2, mix uniformly, obtain the mixture;

[0066] Step 2: The mixture is roasted at a roasting temperature of 780° C. for a roasting time of 4 hours to obtain a roasted material;

[0067] Step 3: Add hydrochloric acid to the roasting material to react, and the addition ratio is [H + ] / WO 3 The ratio of the amount of substances is 3, the reaction temperature is 95°C, and the reaction time is 3h, to obtain a solid-liquid mixture;

[0068] Step 4: Filtrate the solid-liquid mixture, and wash the filter residue three times with heated anhydrous brine to obtain a solution containing cobalt and nickel and tungstic acid from the filter residue; after drying, tungstic acid is added to ammonia water, where the initial ammonia concentration is 160g / l, at 90°C React ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com