Composite water permeable brick and preparation method thereof

A technology of permeable bricks and polymers, which is applied to pavements paved with prefabricated blocks, pavement details, and buildings. Improve aesthetics, prolong service life, reduce water damage and swelling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing the above-mentioned composite permeable brick, comprising the following steps:

[0050] a) providing a concrete slab body layer, on which a layer of bonding layer material is arranged;

[0051] b) A layer of flexible wear layer material is placed on the bonding layer material, and cured to obtain a composite permeable brick.

[0052] In the preparation method provided by the present invention, a concrete slab body layer is firstly provided. The preparation method of the concrete slab body layer is not particularly limited in the present invention, and it can be prepared by conventional prefabrication or stamping forming methods.

[0053]After the concrete slab body layer is obtained, a layer of adhesive layer material is arranged on the concrete slab body layer, preferably by spraying or brushing the adhesive layer material on the concrete slab body layer. Generally, the bonding layer material can be set after...

Embodiment 1

[0060] 1) Composite permeable brick

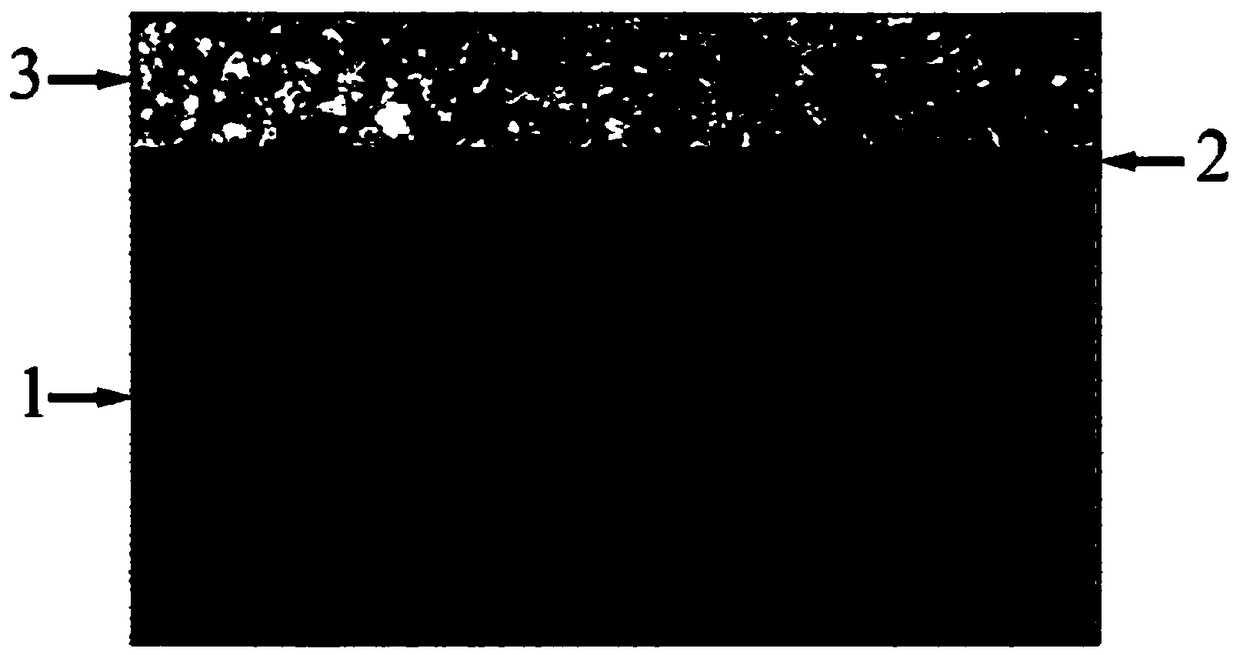

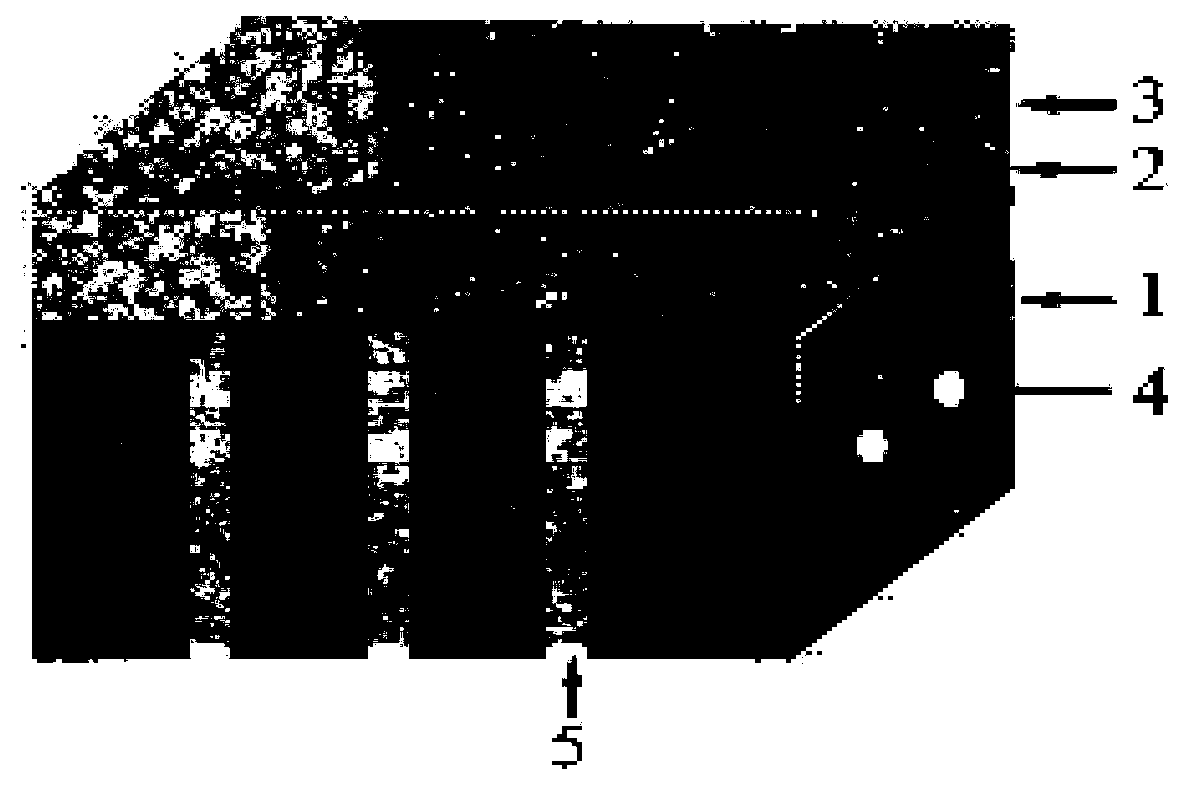

[0061] Such as figure 2 As shown, the composite permeable brick provided in this embodiment includes a concrete slab body layer 1, an adhesive layer 2, and a flexible wear layer 3 from bottom to top, wherein the concrete slab body layer 1 is provided with a horizontal drainage channel 4 and a longitudinal drainage channel 5 .

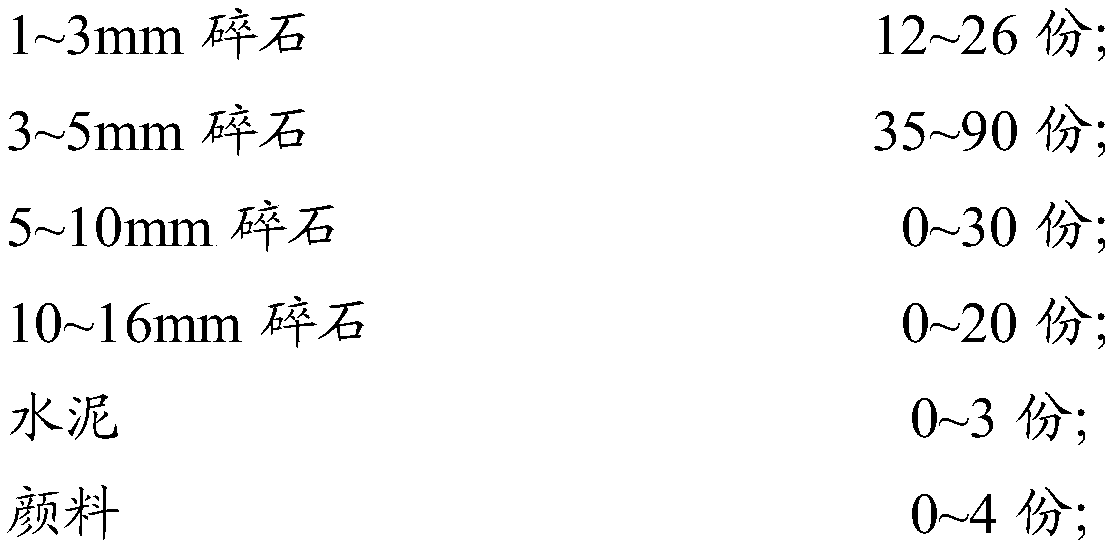

[0062] In the present embodiment, the inner diameter of the drainage pipe in the concrete slab body layer 1 is 10mm, and the distance between two adjacent drainage pipes in the same setting direction is 100mm; the material of the concrete slab body layer 1 is cement steel fiber crushed stone concrete (material The mass ratio is cement: crushed stone: steel fiber: SBR fatty alcohol polyoxyethylene ether compound modified emulsified asphalt = 390: 1432: 40: 55, water: cement = 97: 390; the steel fiber is shear wave type, its The length is 25mm, the equivalent diameter is 0.5mm, the length-to-diameter ratio is 50, a...

Embodiment 2

[0076] 1) Composite permeable brick

[0077] Such as figure 2 As shown, the composite permeable brick provided in this embodiment includes a concrete slab body layer 1, an adhesive layer 2, and a flexible wear layer 3 from bottom to top, wherein the concrete slab body layer 1 is provided with a horizontal drainage channel 4 and a longitudinal drainage channel 5 .

[0078] In the present embodiment, the inner diameter of the drainage pipe in the concrete slab body layer 1 is 20mm, and the distance between two adjacent drainage pipes in the same setting direction is 120mm; the material of the concrete slab body layer 1 is cement polyester fiber gravel concrete ( The mass ratio of materials is cement: gravel: polyester fiber: fatty alcohol polyoxyethylene ether modified polymer emulsion = 424: 1390: 2: 9, water: cement = 106: 424 = 0.25; polyester fiber is filamentous , the length is 30mm, the diameter is 20μm, the crushed stone specification and mass ratio are 5-10mm:10-20mm=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com