A preparation method for preparing pesticide-degrading bacteria organic fertilizer from pig farm biogas residue

A pesticide degradation and organic fertilizer technology, applied in the direction of organic fertilizers, biochemical equipment and methods, and methods based on microorganisms, can solve the problems of farmland pollution, low utilization efficiency, and large biogas residue production, and achieve soil improvement and increase Fertility retention and the effect of improving the activity of soil enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

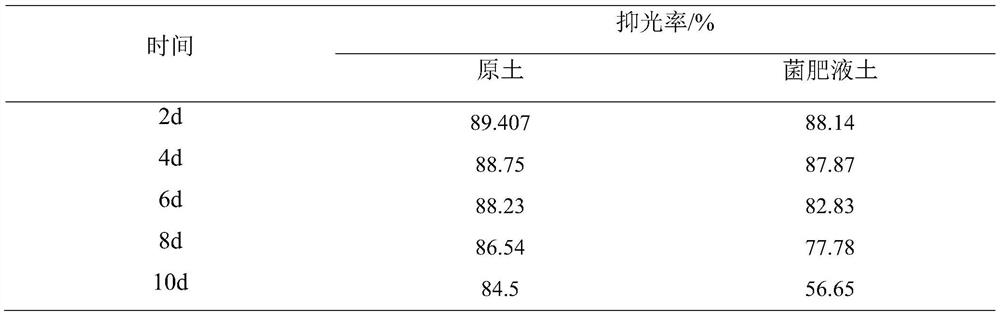

Examples

Embodiment 1

[0024]The preparation steps are as follows:

[0025]1. Preparation of bacteria: HD-1 bacterial liquid for fresh overnight.

[0026]2. Preparation of an envelope material: Take a quantity of distilled water to be heated to about 90 ° C, add polyvinyl alcohol to stir, stir the stirring to it completely dissolved, prepared a mass fraction of 8% polyvinyl alcohol solution, and the seal is stored for cooling to room temperature.

[0027]3. Slag pretreatment: The water content of 60% is dried at a high temperature of 150 ° C for 72 h.

[0028]4, precursive treatment: use a pulverizer to pulverize the zeolite, and the slag is divided into 60 mesh powder.

[0029]5. Comparative: 20 parts of zeolite, 75 parts of the biogoura, and a quantity of HD-1 bacteria were added during the mixing process.

[0030]6. Put the compound of the compound into the disc granulator for granulation, and add 8% polyvinyl alcohol, compix by 0.2ml · g-1, The particle size range is 3 ~ 5mm, so that the number of effective live bacter...

Embodiment 2

[0033]The preparation method is as in Example 1, which is different:

[0034]1. Preparation of bacteria: HD-1 bacterial liquid for fresh overnight.

[0035]2. Preparation of the envelope material: Take a certain amount of distilled water to heat about 90 ° C, add polyvinyl alcohol to stir, stir the stirring to it completely dissolved, prepared a mass fraction of 10% polyvinyl alcohol solution, and the seal is stored for cooling to room temperature.

[0036]3. Slag pretreatment: The water content of 65% is dried at 150 ° C for 72 h.

[0037]4, precursive treatment: use a pulverizer to pulverize the zeolite, and the slag is divided into 60 mesh powder.

[0038]5. Comparative: 25 parts of zeolite, 70 parts of the bridges are mixed, and a certain amount of HD-1 bacteria is added during the mixing process.

[0039]6. Put the complicated material into the disc granulator for granulation, and add 10% polyvinyl alcohol, complicate 0.2ml · g-1, The particle size range is 3 ~ 5mm, so that the number of effecti...

Embodiment 3

[0042]The preparation method is in Examples 1, 2, which is different:

[0043]1. Preparation of bacteria: HD-1 bacterial liquid for fresh overnight.

[0044]2. Preparation of the envelope material: Take a quantity of distilled water to heat about 90 ° C, add polyvinyl alcohol to stir, stir the stirring to it completely dissolved, prepared a mass fraction of 15% polyvinyl alcohol solution, and the seal is allowed to cool to room temperature.

[0045]3. Slag pretreatment: The water content of 65% is dried at 150 ° C for 72 h.

[0046]4, precursive treatment: use a pulverizer to pulverize the zeolite, and the slag is divided into 60 mesh powder.

[0047]5. Comparative: 30 parts of zeolite, 65 parts of the biogoura, and a quantity of HD-1 bacteria is added during the mixing process.

[0048]6. Put a compound of the compound into the disc granulator for granulation, and add 15% polyvinyl alcohol, complicate than 0.2ml · g-1, The particle size range is 3 ~ 5mm, so that the number of effective live bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com