Wear-resistant and hydrolysis-resistant PA66 (polyamide 66) material and preparation method thereof

A technology of PA66 and hydrolysis resistance, which is applied in the field of PA66 materials and its preparation, can solve the problems of low hydrolysis resistance retention rate, low wear resistance strength, and unstable performance, and achieve low cost, stable product performance, and improved wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

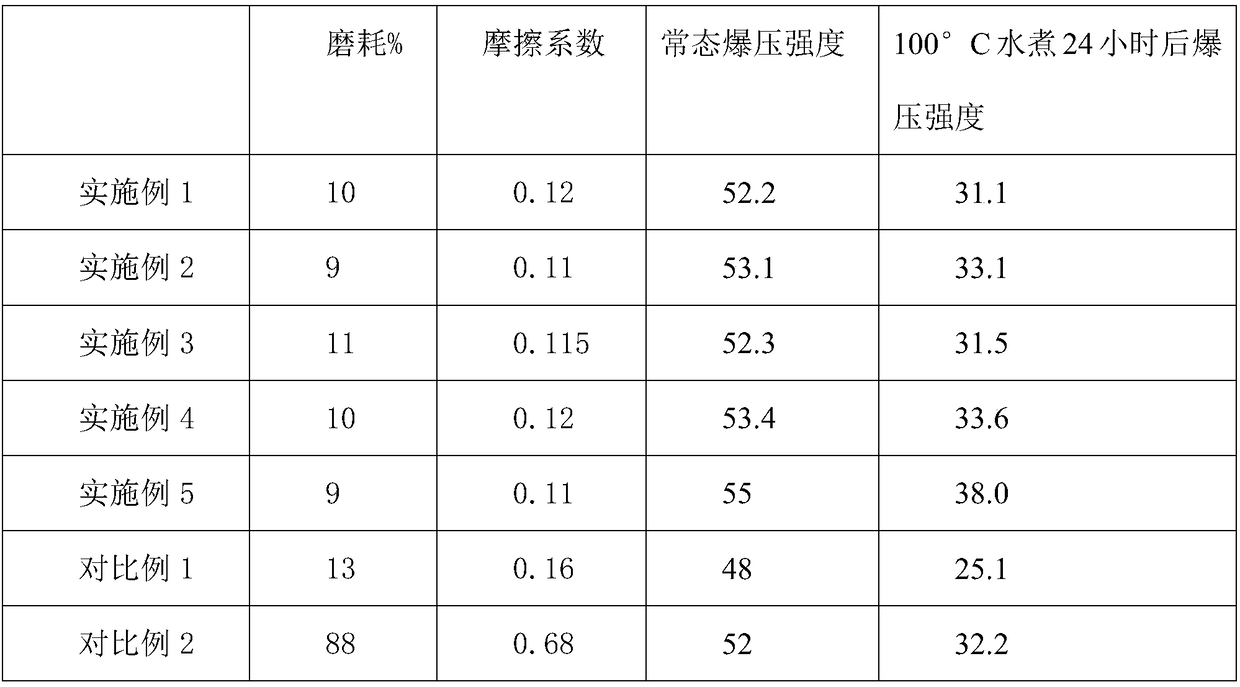

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a wear-resistant and hydrolysis-resistant PA66 material is composed of the following raw materials in parts by weight: 85 parts of PA66 material, 55 parts of synthetic rubber, 18 parts of new antioxidant, 25 parts of compatibilizer, sodium calcium silicon 50 parts of salt glass, 22 parts of molybdenum disulfide. Wherein the synthetic rubber is hydroxyl-terminated polybutadiene; the novel antioxidant is a 1:1 mixture of dialkyl diphenylamine and isooctyl acrylate.

[0022] (1) Add PA66 material and synthetic rubber, then add compatibilizer and mix to obtain the first group of mixture;

[0023] (2) Add soda-lime silicate glass to the first group of mixtures, and stir at a stirring speed of 500 rpm to form the second group of mixtures;

[0024] (3) Slowly add molybdenum disulfide to the second group of mixture, stir at a constant speed, and let stand for 2 hours.

Embodiment 2

[0026] In the embodiment of the present invention, a wear-resistant and hydrolysis-resistant PA66 material is composed of the following raw materials in parts by weight: 105 parts of PA66 material, 75 parts of synthetic rubber, 25 parts of new antioxidant, 35 parts of compatibilizer, sodium calcium silicon Salt glass 65 parts, molybdenum disulfide 30 parts. Wherein the synthetic rubber is hydroxyl-terminated polybutadiene; the novel antioxidant is a 1:1 mixture of dialkyl diphenylamine and isooctyl acrylate.

[0027] (1) Add PA66 material and synthetic rubber, then add compatibilizer and mix to obtain the first group of mixture;

[0028] (2) Add soda-lime silicate glass to the first group of mixtures, and stir at a stirring speed of 500 rpm to form the second group of mixtures;

[0029] (3) Slowly add molybdenum disulfide to the second group of mixture, stir at a constant speed, and let stand for 3 hours.

Embodiment 3

[0031] In the embodiment of the present invention, a wear-resistant and hydrolysis-resistant PA66 material is composed of the following raw materials in parts by weight: 95 parts of PA66 material, 60 parts of synthetic rubber, 20 parts of new antioxidant, 29 parts of compatibilizer, sodium calcium silicon 57 parts of salt glass and 25 parts of molybdenum disulfide. Wherein the synthetic rubber is hydroxyl-terminated polybutadiene; the novel antioxidant is a 1:1 mixture of dialkyl diphenylamine and isooctyl acrylate.

[0032] (1) Add PA66 material and synthetic rubber, then add compatibilizer and mix to obtain the first group of mixture;

[0033] (2) Add soda-lime silicate glass to the first group of mixtures, and stir at a stirring speed of 500 rpm to form the second group of mixtures;

[0034] (3) Slowly add molybdenum disulfide to the second group of mixture, stir at a constant speed, and let stand for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com