Edible vinegar and brewing method thereof

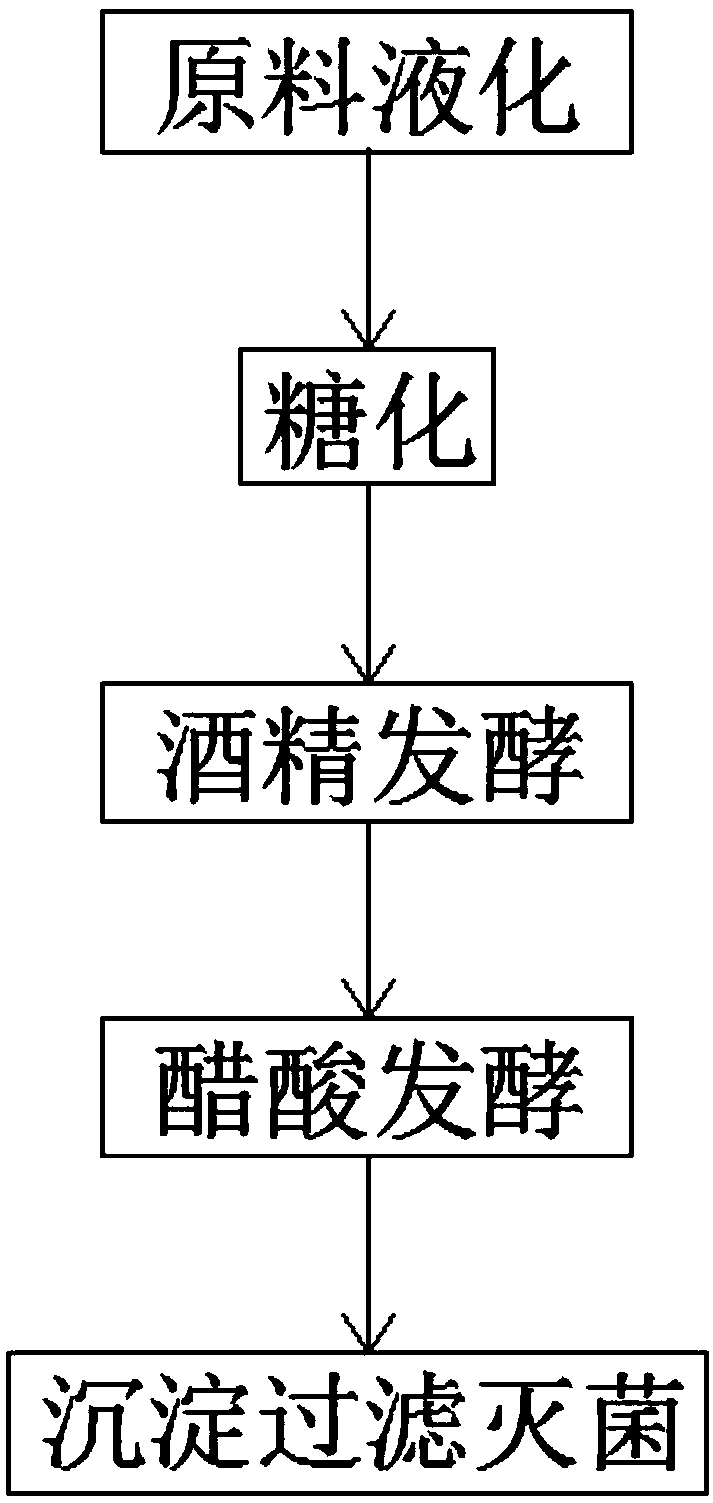

An edible vinegar and process technology, applied in the field of food processing, can solve the problems of reducing production efficiency, increasing the workload of workers, prolonging brewing time, etc., and achieving the effects of saving time, saving labor costs, and shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the content of the present invention is not limited to the following embodiments.

[0025] Preparatory work: Cultivate strains: put acetic acid bacteria Hu 1.01 into an aqueous solution with an alcohol concentration of 3.3-3.5w% and put it into a 50L conical flask for cultivation, and use the sterilized vinegar stock solution to adjust the concentration of acetic acid to 0.9-1.3 w%, the culture temperature is 30-35℃, and the ventilation volume is 0.39m 3 / h; cultivated for 24 hours to obtain acetic acid secondary bacteria; wherein the acidity of the obtained acetic acid secondary bacteria is 1.8-2.0g / ml.

[0026] 1) Raw material liquefaction: put 600 kg of rice into 900 kg of water and soak for 4 hours, then grind it into 60-70 mesh rice milk, use 1.2 kg of Na 2 C0 3 Adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com