Low-nitrogen condensation type double-hearth gas boiler system

A gas-fired boiler, condensing technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of nitrogen oxide pollution emissions, poor energy saving effect, low thermal efficiency, etc., to reduce nitrogen oxides, reduce fuel combustion temperature , the effect of protecting the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

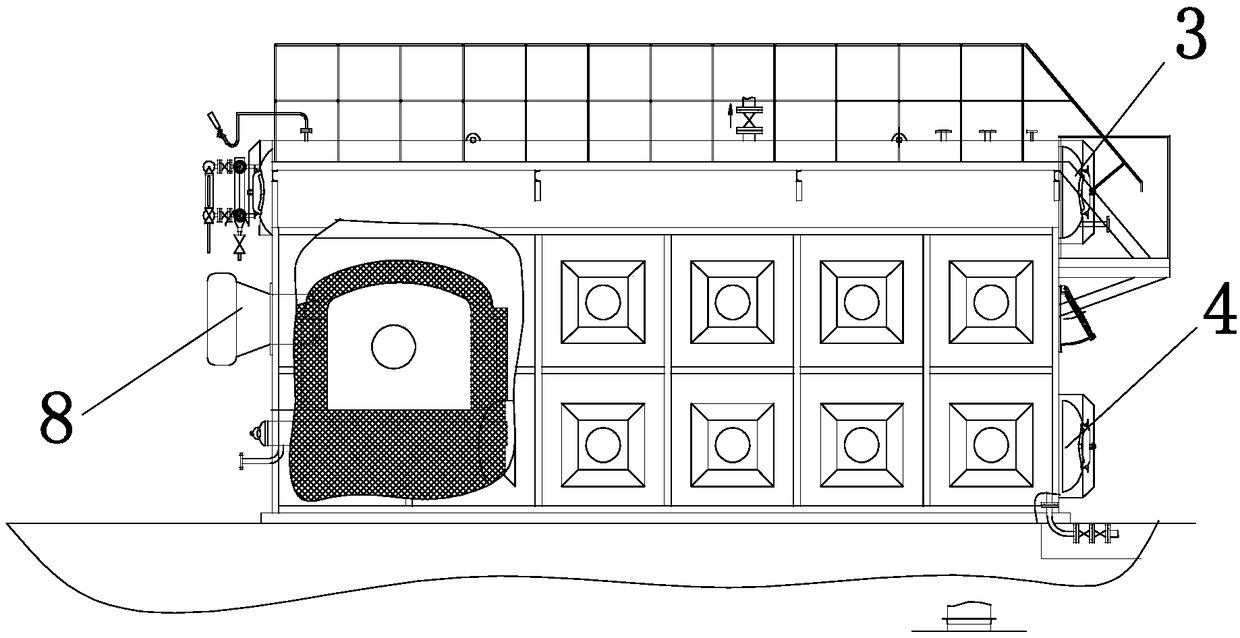

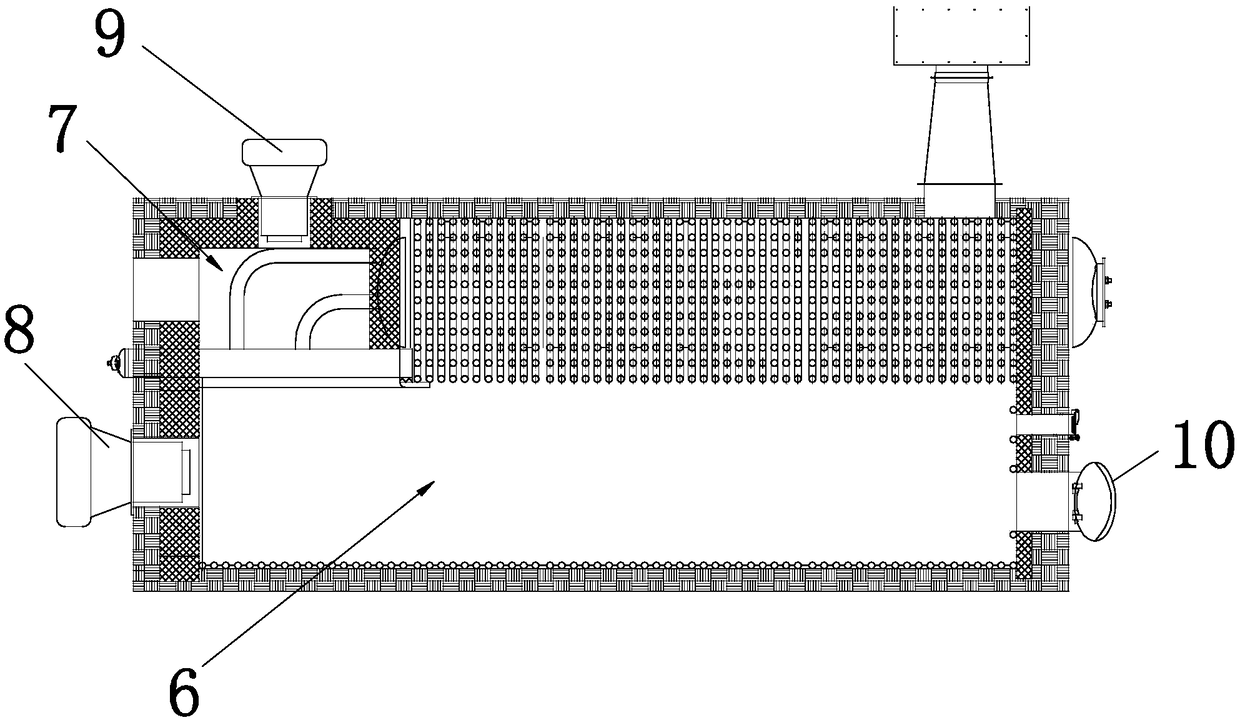

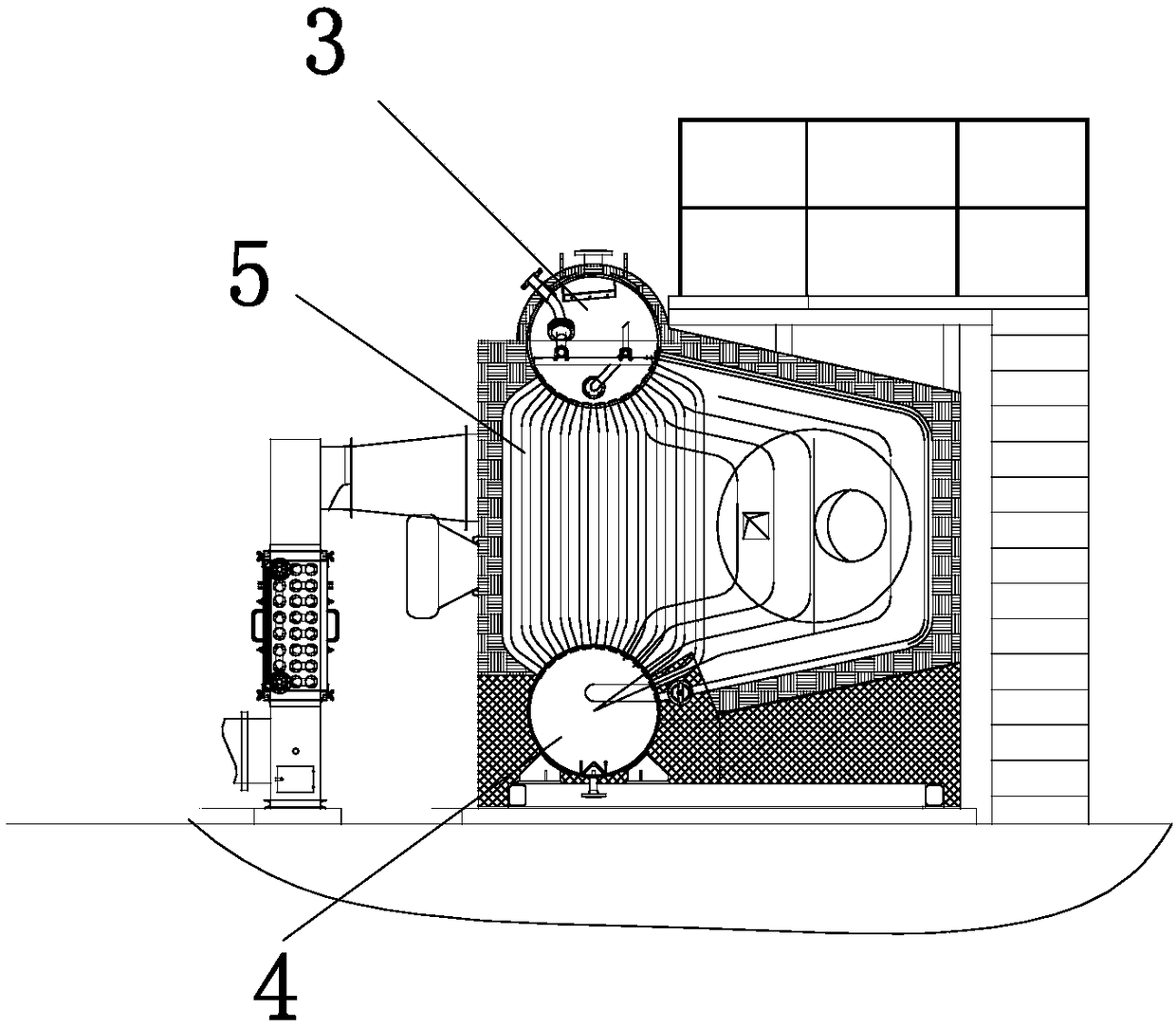

[0031] Such as Figure 1-Figure 7 As shown, the present invention provides a low-nitrogen condensing double-hearth gas boiler system, which includes a furnace, a convection chamber 29, an explosion-proof door device, a waste heat recovery energy-saving device and a low-nitrogen combustion device.

[0032] The upper and lower parts of the convection chamber 29 are respectively provided with an upper drum 3 and a lower drum 4, and a convection tube bundle 5 is connected between the upper drum 3 and the lower drum 4. The furnace includes a main furnace 6 and an auxiliary furnace separated from each other. 7. The main furnace 6 and the auxiliary furnace 7 are respectively provided with a main burner 8 and an auxiliary burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com