Method for calculating equivalent thermal conductivity coefficients of hollow glass beads

A technology of equivalent thermal conductivity and glass microspheres, which is applied in the field of materials, can solve problems such as the inability to directly measure the thermal conductivity of a single hollow glass microsphere, and achieve the effects of high calculation accuracy, convenient use, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

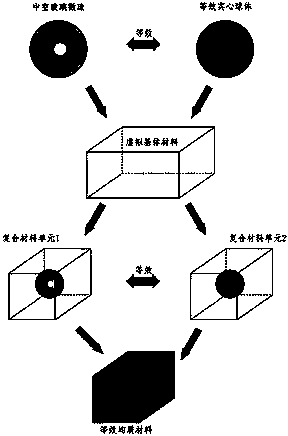

[0059] Such as Figure 1-Figure 8 As shown, a method for calculating the equivalent thermal conductivity of hollow glass microspheres, the calculation method includes the following steps:

[0060] Step 1: Embed hollow glass microspheres and their equivalent solid spheres in a virtual matrix material at the same volume ratio, and establish two periodic composite material systems 1 and 2;

[0061] Step 2: Establish representative material units 1 and 2 in periodic composite material systems 1 and 2, respectively;

[0062] Step 3: Apply different temperature boundary conditions on the two opposite surfaces of composite material elements 1 and 2, and then use the finite element method to calculate the heat flow distribution on a certain temperature surface;

[0063] Step 4: Calculate the equivalent thermal conductivity of composite material unit 1 by using the composite material homogenization method;

[0064] Step 5: Assuming that the thermal conductivity of the equivalent soli...

Embodiment 2

[0103] Hollow glass beads with an outer diameter of 58.64 microns and a wall thickness of 1.58 microns are used to calculate and determine their thermal conductivity, including the following:

[0104] 1. The thermal conductivity of the hollow glass bead glass wall material is 1.03W / (mK), the thermal conductivity of the air inside the package is 0.023 W / (mK), and the thermal conductivity of the virtual matrix material is 0.93W / (mK);

[0105] 2. Apply temperatures of 10 degrees Celsius and 30 degrees Celsius on the two parallel sides of composite material units 1 and 2, respectively;

[0106] To illustrate the robustness of the method of the present invention:

[0107] (1) During the calculation process, the volume ratios (10%, 20%, 30%, 40%) of four different hollow glass microspheres and their equivalent solid spheres in the virtual composite system are investigated, Figure 8 What is shown is the prediction result of the thermal conductivity of hollow glass microspheres unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com