Prestress-assisted nanoimprint-based high-density diffraction grating making method

A technology of nanoimprinting and diffraction grating, which is applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problems of expensive molds, inability to obtain smaller sizes, and damage molds, so as to solve the problems of expensive equipment, reduce manufacturing costs and cycle time , easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

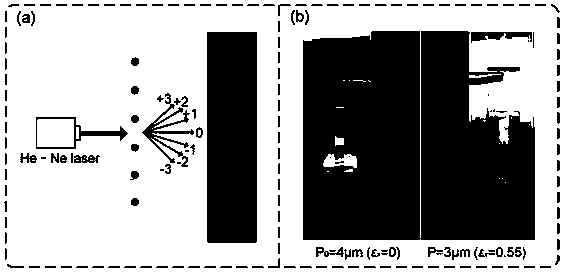

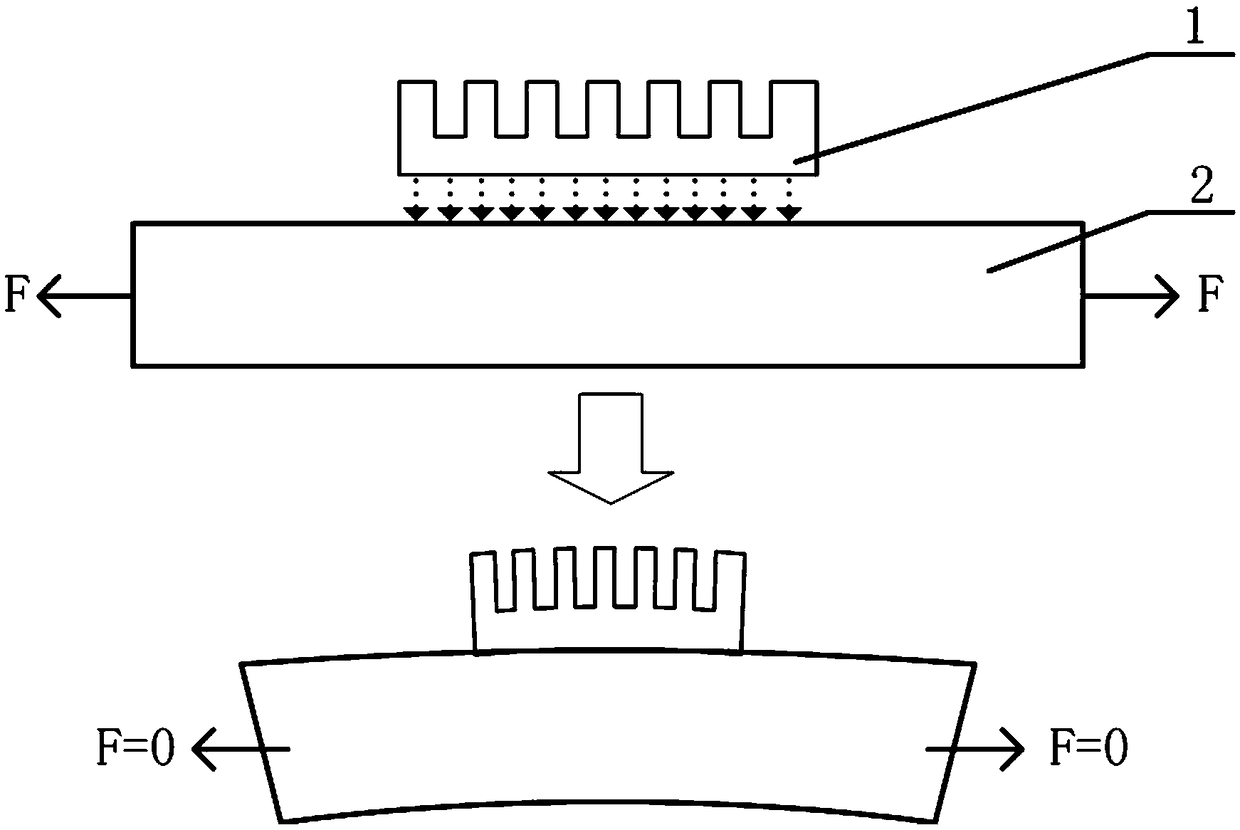

[0029] refer to figure 1 , the present invention a kind of preparation method of pre-stress assisted nano-imprinting to manufacture high-density diffraction grating, comprising the following steps:

[0030] a. Making a grating master by nanoimprinting process;

[0031] b. Transfer the grating pattern of the master plate in step a to the PDMS film to make a patterned PDMS grating film 1;

[0032] c, making PDMS flexible substrate 2;

[0033] d. Clamp the PDMS flexible substrate 2 on the manual micro-displacement platform and stretch it to a certain length;

[0034] e. Adhering the patterned PDMS grating film 1 on the pre-stretched PDMS flexible substrate 2;

[0035] f. Release the prestress.

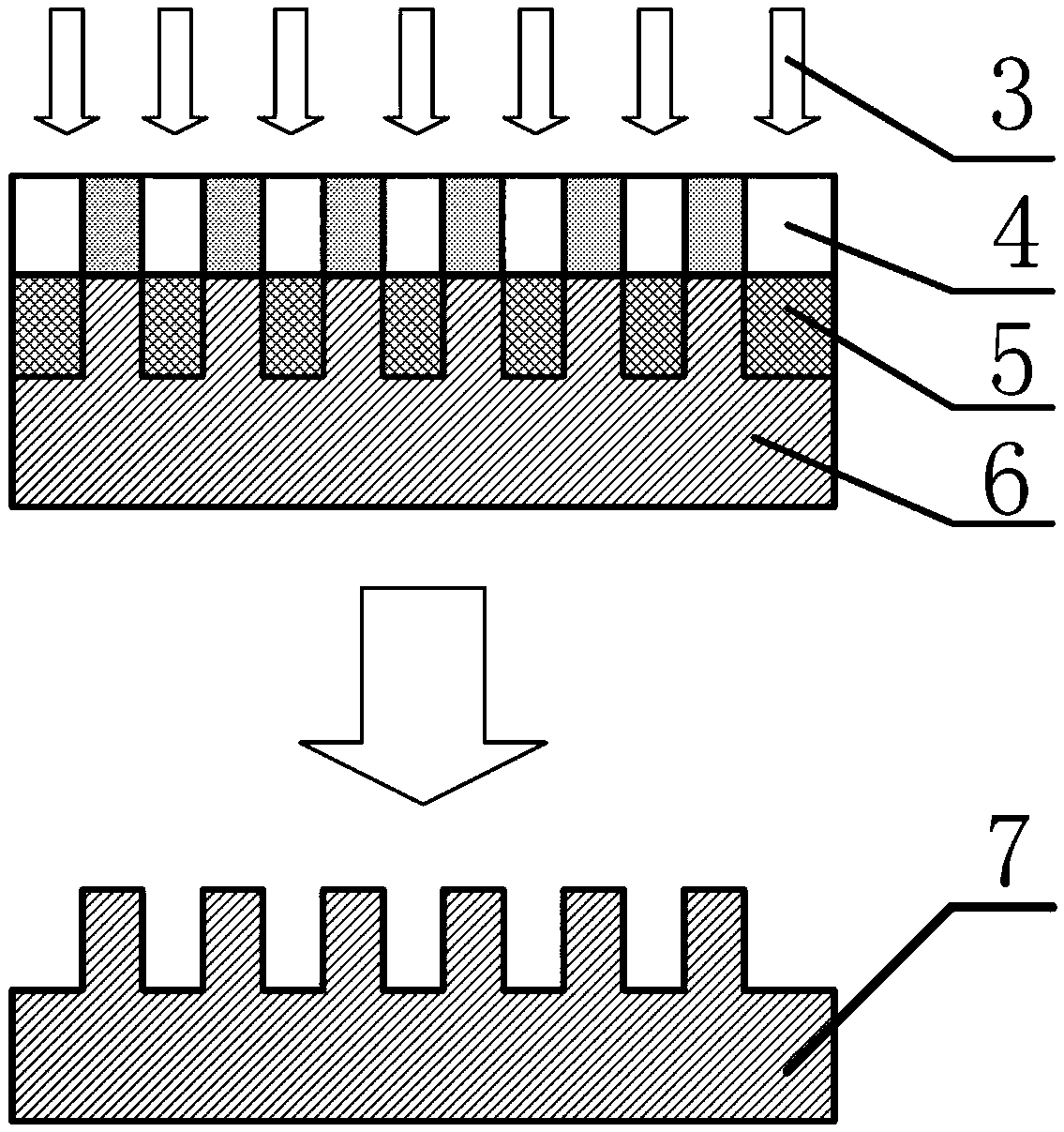

[0036] For specific implementation, refer to figure 2 , step a: making a grating master template by using ultraviolet lithography technology. First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com