Heat pipe backboard type data center

A data center and backplane-type technology, applied in the field of heat pipe backplane-type data centers, can solve the problems of complex control system, difficult control of air-conditioning system pipeline load and refrigerant flow, and less obvious energy-saving effect of heat dissipation information computer room, etc. , to achieve the effect of reduced fan power, small footprint, and increased heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

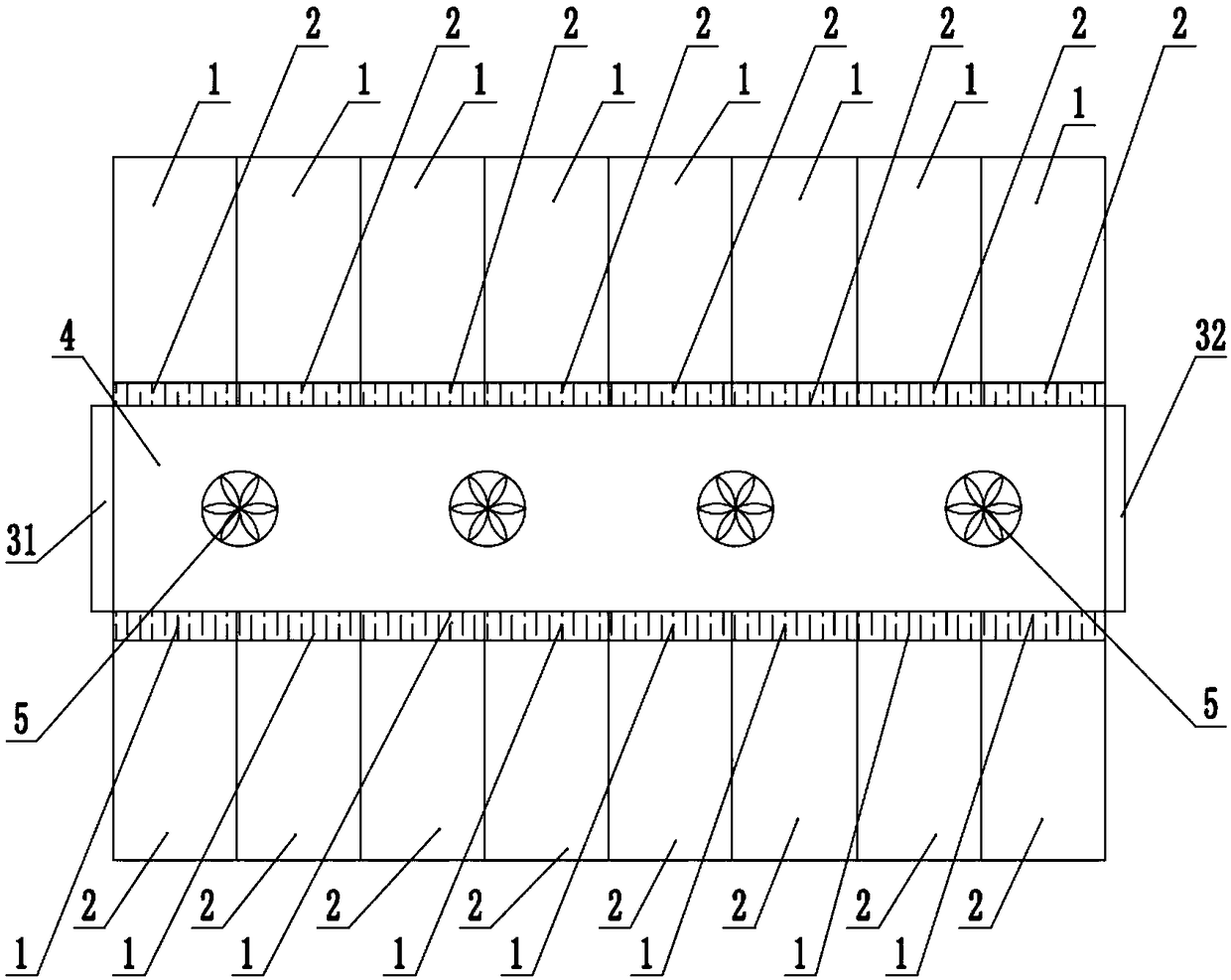

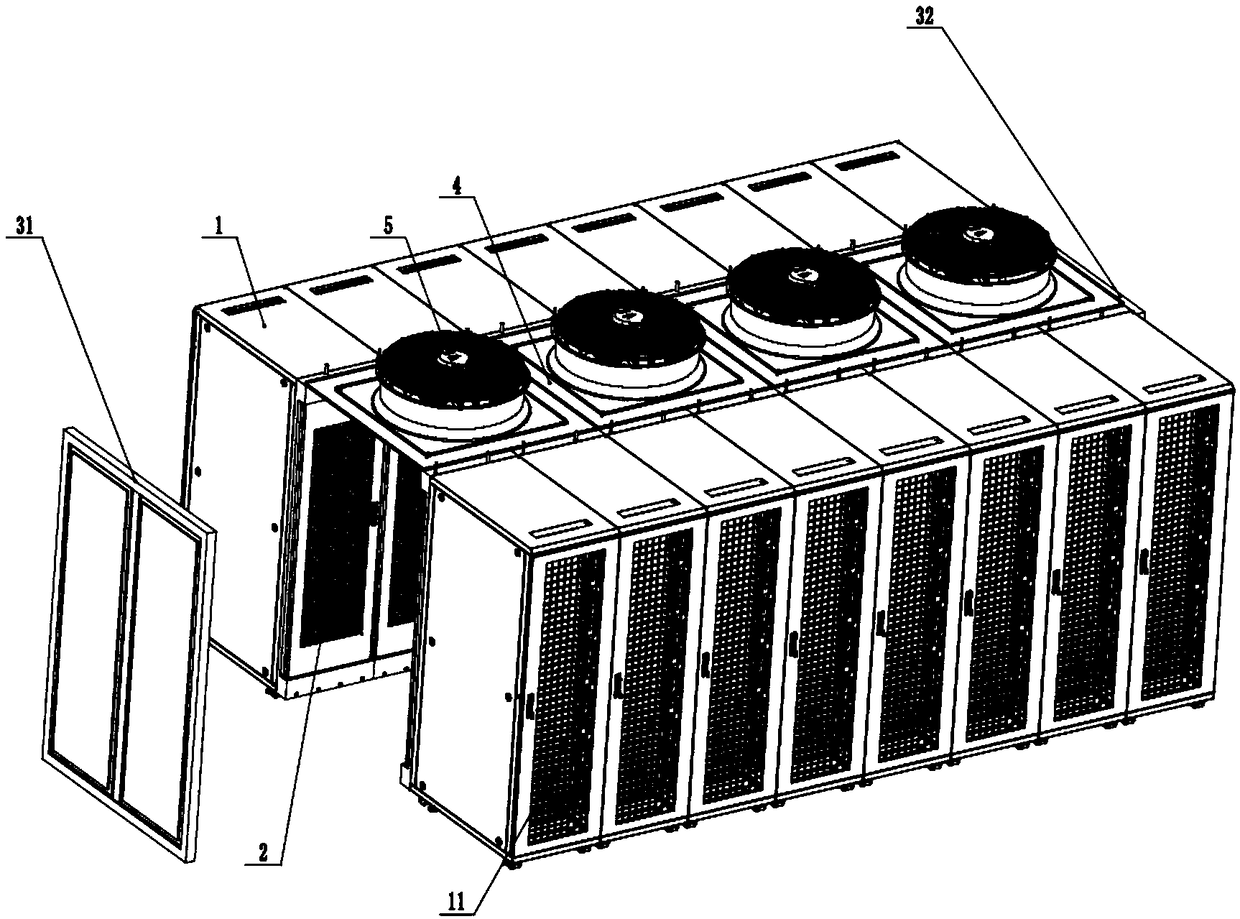

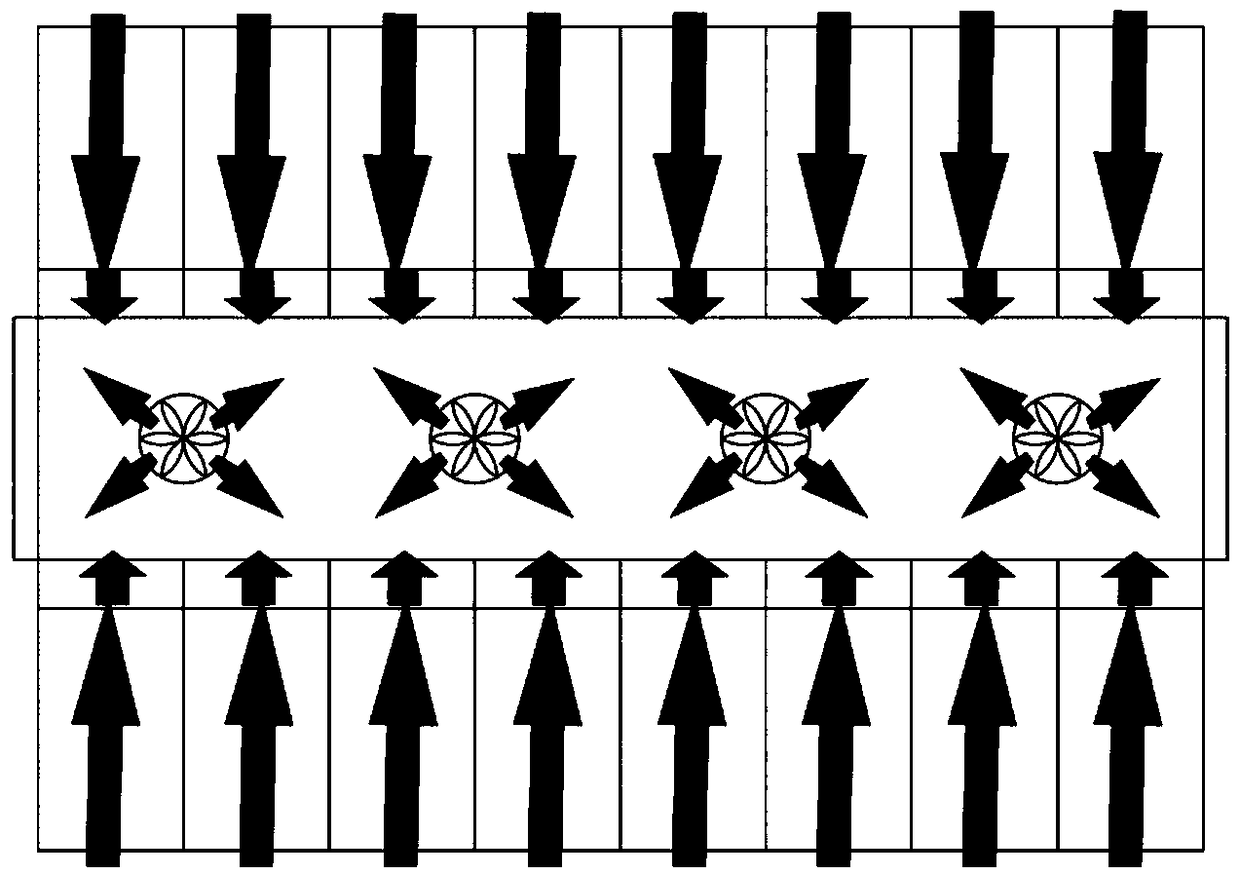

[0026] Such as figure 1 with 2 As shown, the heat pipe backplane data center of the present invention includes a plurality of cabinets 1, a number of backplane air conditioners 2 corresponding to the cabinets, a closed top cover 4, a front door 31, a rear door 32 and a plurality of fans 5; A plurality of cabinets 1 are formed in front and rear rows of cabinet groups, and the front row of cabinet groups and the rear row of cabinet groups are arranged side by side; each of the back panel air conditioners 2 is installed on the rear door of each corresponding cabinet 1, and the back panel air conditioners 2 Rotationally installed on one side of the rear door of the cabinet 1, and can be rotated by rotating the rear door; the front row cabinet group and the rear cabinet group are placed back to back, that is, the back panel air conditioner 2 on the front row cabinet group and the rear cabinet group A cold aisle is formed in the middle of the backplane air conditioner 2 on the row ...

specific Embodiment approach 2

[0033] Please refer to Figure 4 , Figure 5 with Image 6 As shown, in this embodiment, the cabinet doors 11 of the front row cabinet group and the rear cabinet group are placed face to face, that is, each row of cabinet groups forms a closed door 11 with the closed top cover 4, the front door 31 and the rear end surface 32 respectively. cold aisle. The back panel air conditioner 2 is installed on the back door of the cabinet 1. The fan 5 sucks cold air from the environment and sends it into the cold aisle. The cold air enters the cabinet 1 to cool the electronic equipment through the cold aisle. The hot air blown from the cabinet 1 directly passes through the back panel air conditioner 2. The heat exchanger is cooled, so that the cooler air flow discharged from the back panel air conditioner 2 is recirculated into the environment. All the other parts are the same as the first embodiment, and the working method is also the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com