Quinoa shampoo and preparation method thereof

A shampoo and quinoa technology, which is applied in hair care, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of no quinoa extract technical solutions and no quinoa extract shampoo products, etc., and achieve The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

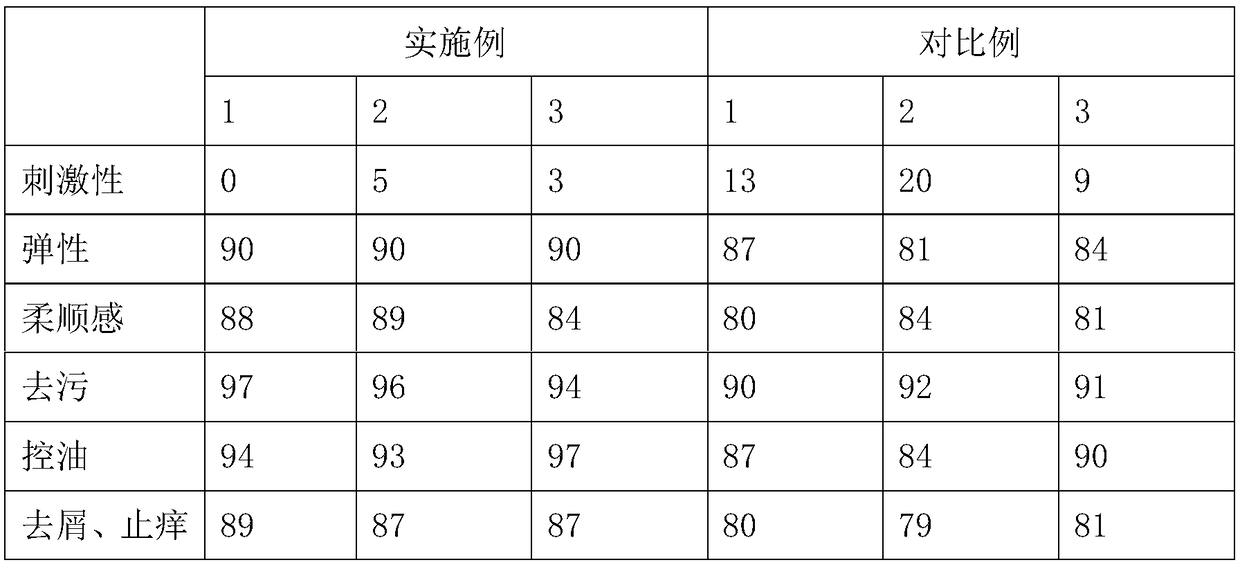

Examples

Embodiment 1

[0052] A quinoa shampoo, the quinoa shampoo comprises the following ingredients in terms of weight percentage: 3% quinoa extract A; 4% quinoa extract B; 2% quinoa extract C; 0.5% lauryl alcohol Sodium Polyether Sulfate; 0.2% Cocamidopropyl Betaine; 0.1% Cocamidomethyl MEA; 0.02% Etidronate; 0.1% Citric Acid; Erjiao; 0.1% extract of Pinus chinensis leaves; 0.1% methylparaben; remaining deionized water; pH value is 6.9.

[0053] The quinoa shampoo manufacturing method comprises the following steps: (1) adding deionized water to a reaction vessel, raising the temperature to 80°C, adding the anionic surfactant, the zwitterionic surfactant and the nonionic surfactant in sequence Surfactant, stirred, and mixed evenly; (2) cooling the mixed solution obtained in the step (1) to 60° C., and then adding the quinoa extract A, the quinoa extract B and The quinoa extract C, and add a certain amount of deionized water again to continue stirring, so that it is evenly mixed; (3) keep the tem...

Embodiment 2

[0058] A quinoa shampoo, the quinoa shampoo comprises the following ingredients in terms of weight percentage: 7% quinoa extract A; 6% quinoa extract B; 5% quinoa extract C; 1% lauroyl Sodium Sarcosinate; 0.3% Coco Cocamidopropyl Hydroxysultaine; 0.2% Cocamide MEA; 0.05% EDTA-2Na; 0.5% Citric Acid; 1% PEG-120 Methyl Glucodioleic Acid Esters; 0.5% cationic hyaluronic acid; 0.8% ginger extract; 0.2% Kasone; the rest deionized water; pH value is 7.0.

[0059] The method for manufacturing the quinoa shampoo comprises the following steps: (1) adding deionized water to a reaction vessel, raising the temperature to 85°C, adding the anionic surfactant, the zwitterionic surfactant and the nonionic surfactant in sequence Surfactant, stirring, to make it mix evenly; (2) cooling the mixed solution obtained in the step (1) to 65°C, and then adding the quinoa extract A, the quinoa extract B and The quinoa extract C, and add a certain amount of deionized water again to continue stirring, so...

Embodiment 3

[0064] A quinoa shampoo, the quinoa shampoo comprises the following ingredients in terms of weight percentage: 3%-7% quinoa extract A; 6% quinoa extract B; 4% quinoa extract C; 1 % Sodium Lauroyl Sarcosinate; 0.5% Sodium Cocoamphoacetate; 0.3% Cocamide DEA; 0.1% Chelating Agent; 3% pH Sodium Citrate; 2.5% PEG-7 Glyceryl Cocoate; 0.5% Poly Quaternary ammonium salt 7; 2% jujube bark extract; 0.3% methylparaben; the rest deionized water; pH value is 7.1.

[0065] The manufacturing method of the quinoa shampoo comprises the following steps: (1) adding deionized water into a reaction vessel, raising the temperature to 90°C, adding the anionic surfactant, the zwitterionic surfactant and the nonionic surfactant in sequence Surfactant, stirring, to make it mix evenly; (2) cooling the mixed solution obtained in the step (1) to 65°C, and then adding the quinoa extract A, the quinoa extract B and The quinoa extract C, and add a certain amount of deionized water again to continue stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com