NiZn ferrite magnetic sheet, and preparation method and application thereof

A ferrite magnet and green sheet technology, applied in the field of magnetic materials, can solve the problems of low magnetic permeability and affecting the application value of NiZn ferrite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

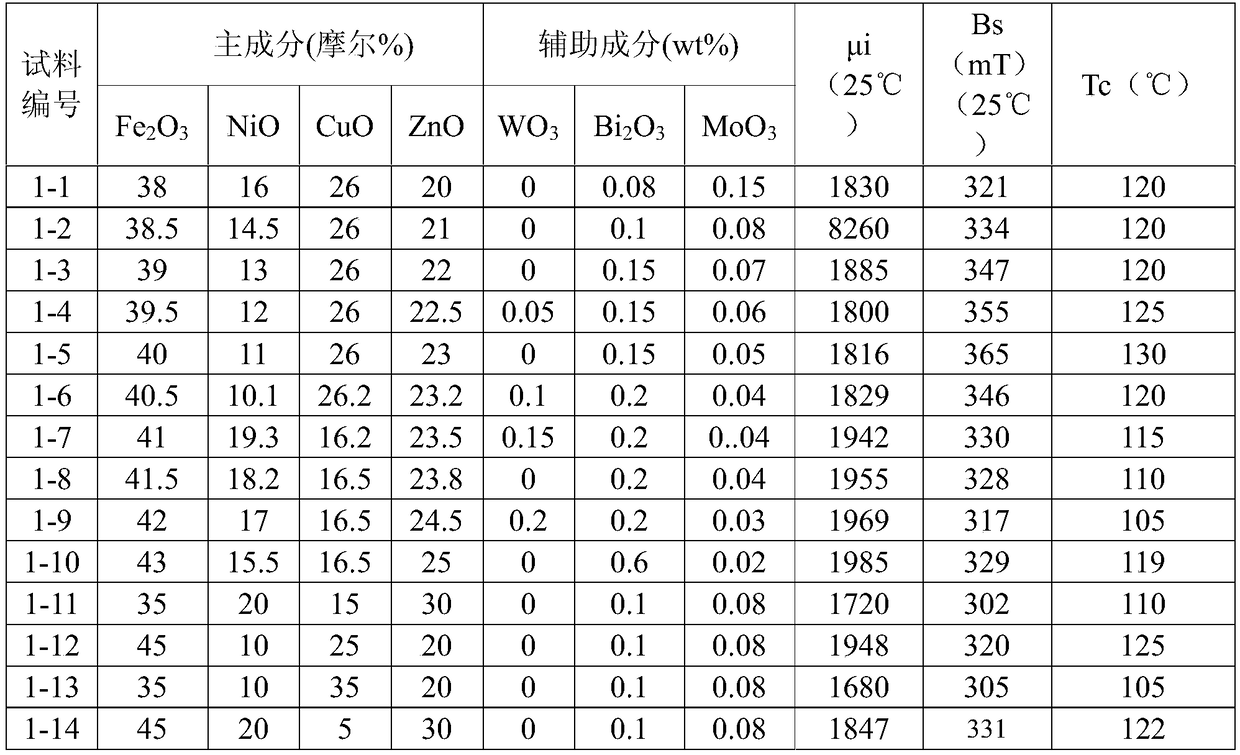

Embodiment 1

[0073] The present embodiment prepares NiZn ferrite magnetic sheet according to the following method:

[0074] (1) the main component Fe of formula quantity 2 o 3 , NiO, ZnO and CuO were placed in a ball mill, added deionized water, mixed and crushed by ball milling, the ball milling time was 30 minutes, and then circulated and mixed for 40 minutes, and then sprayed and granulated to obtain a mixed material. The main components include Fe 2 o 3 , NiO, ZnO and CuO;

[0075] (2) Carry out pre-burning to the mixed material described in step (1) at 700°C, and the pre-burning time is 12h to obtain the calcined powder;

[0076] (3) Mix and crush the calcined powder, binder polyvinyl alcohol, dispersant ethanol and auxiliary components described in step (2) by sand milling for 1 hour to obtain a slurry;

[0077] (4) Cast the slurry described in step (3) to obtain a green sheet with a thickness of 0.03mm, and heat the green sheet from 20°C to a sintering temperature of 900°C at a...

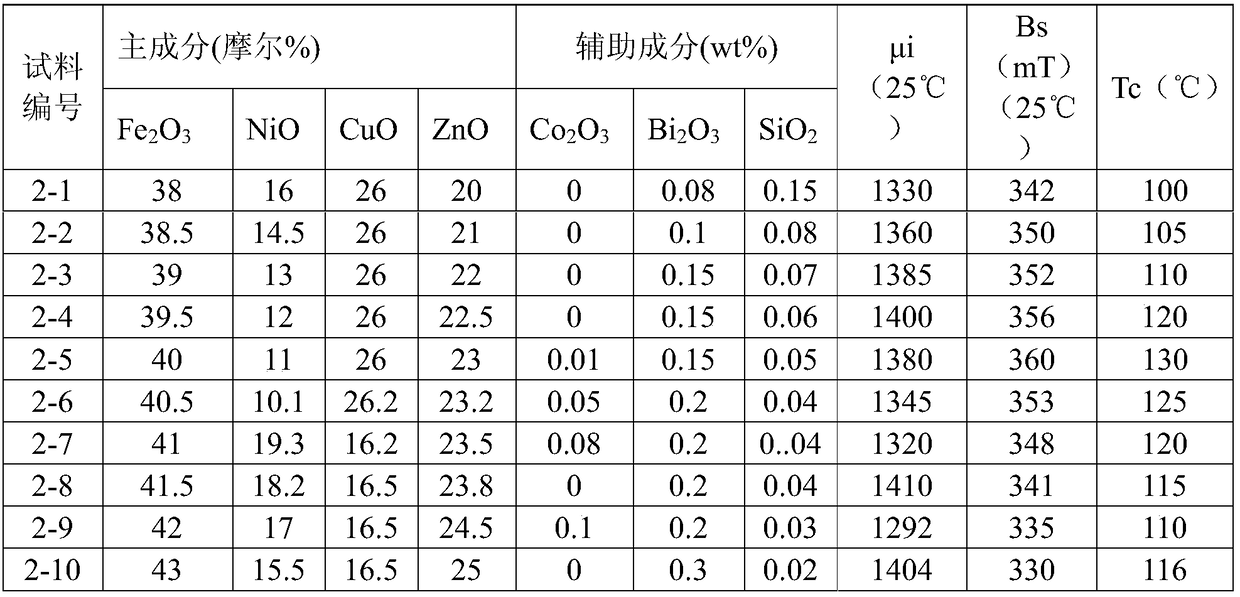

Embodiment 2

[0085] The present embodiment prepares NiZn ferrite magnetic sheet according to the following method:

[0086] (1) the main component Fe of formula quantity 2 o 3 , NiO, ZnO and CuO are placed in a ball mill, added deionized water, mixed and crushed by ball milling, the ball milling time is 100min, and then circulated and mixed for 200min, and then spray granulated to obtain a mixed material, the main component includes Fe 2 o 3 , NiO, ZnO and CuO;

[0087] (2) pre-burn the mixed material described in step (1) at 1000°C, and the pre-fire time is 1h to obtain the pre-fired powder;

[0088] (3) Mix and crush the calcined powder, binder polyvinyl alcohol, dispersant ethanol and auxiliary components described in step (2) by sand milling for 12 hours to obtain a slurry;

[0089] (4) Cast the slurry described in step (3) to obtain a green sheet with a thickness of 0.3mm, and heat the green sheet from 30°C to a sintering temperature of 1200°C at a heating rate of 2°C / min, and ke...

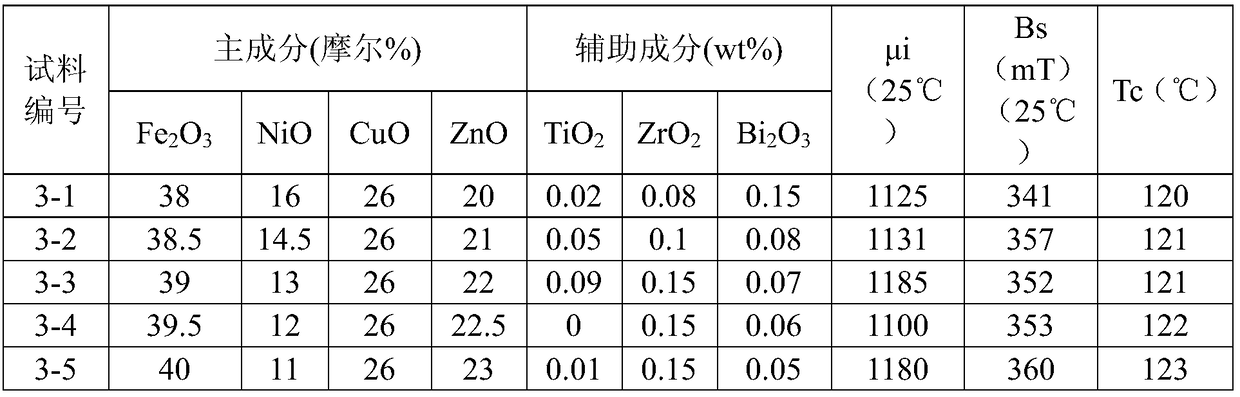

Embodiment 3

[0097] The present embodiment prepares NiZn ferrite magnetic sheet according to the following method:

[0098] (1) the main component Fe of formula quantity 2 o 3 , NiO, ZnO and CuO were placed in a ball mill, added deionized water, mixed and crushed by ball milling, the ball milling time was 60 minutes, and then circulated and mixed for 120 minutes, and then spray granulated to obtain a mixed material. The main components include Fe 2 o 3 , NiO, ZnO and CuO;

[0099] (2) Pre-calcining the mixed material described in step (1) at 850° C. for 6 hours to obtain a pre-calcined powder;

[0100] (3) Mix and crush the calcined powder, binder polyvinyl alcohol, dispersant ethanol and auxiliary components described in step (2) by sand milling for 6 hours to obtain a slurry;

[0101] (4) Cast the slurry described in step (3) to obtain a green sheet with a thickness of 0.15mm. The green sheet is heated from 25°C to a sintering temperature of 1000°C at a heating rate of 1°C / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com