Didecylmethylpropyl ammonium iodide and application thereof

A technology of alkyl methyl propyl ammonium iodide and double ten, which is applied in the field of water purifier formula, can solve the problem of high cost and achieve strong killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

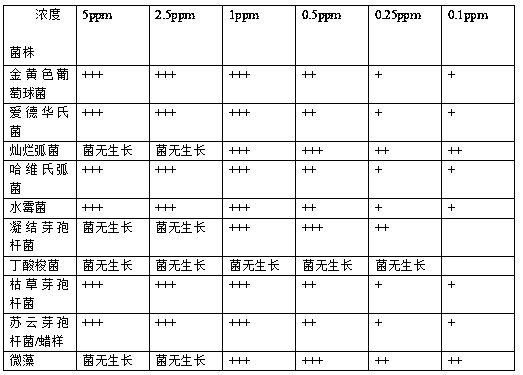

Image

Examples

Embodiment 1

[0014] Example 1, formula: raw materials include water 26%, trimethylammonium 12%, hydrochloric acid 7%, double ten chain essence 22%, propylene oxide 7%, iodine 6%, OP-10 16%, phosphoric acid 4%;

[0015] The preparation steps are as follows:

[0016] Step 1. According to the proportion of the formula, add hydrochloric acid, double ten chain essence, and water in a certain proportion and mix thoroughly. After the temperature rises, add the trimethylammonium solution of the formula amount.

[0017] Step 2. Cool down. After cooling down, add half of the formula amount of propylene oxide, and quickly heat up. After the temperature is stable, add the remaining propylene oxide, continue to heat up to react, and fully react to rise to didecylmethylpropyl Quaternary ammonium salt;

[0018] Step 3. Cool down, add iodine, OP-10, and phosphoric acid in sequence according to the proportion of the formula and mix thoroughly. Stir continuously during the whole reaction process until the ...

Embodiment 2

[0019] Example 2, raw materials include water 25%, trimethylammonium 10%, hydrochloric acid 6%, double ten chain essence 20%, propylene oxide 8%, iodine 8%, OP-10 20%, phosphoric acid 3%;

[0020] The preparation steps are as follows:

[0021] Step 1. According to the proportion of the formula, add hydrochloric acid, double ten chain essence, and water in a certain proportion and mix thoroughly. After the temperature rises, add the trimethylammonium solution of the formula amount.

[0022] Step 2. Cool down. After cooling down, add half of the formula amount of propylene oxide, and quickly heat up. After the temperature is stable, add the remaining propylene oxide, continue to heat up to react, and fully react to rise to didecylmethylpropyl Quaternary ammonium salt;

[0023] Step 3. Cool down, add iodine, OP-10, and phosphoric acid in sequence according to the proportion of the formula and mix thoroughly. Stir continuously during the whole reaction process until the whole rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com