A pressure control device and a pressure increase and decrease control method

A technology of pressure control and control method, which is applied in the direction of fluid pressure actuators, fluid pressure converters, fluid pressure actuator system components, etc., and can solve the difficulty of ensuring control accuracy and work stability, and the difficulty of precise control of hydraulic systems Increase the problem of unfavorable power supply and oil supply, achieve the effect of high adjustment accuracy and stability, reduce structural cost and energy consumption, and improve accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

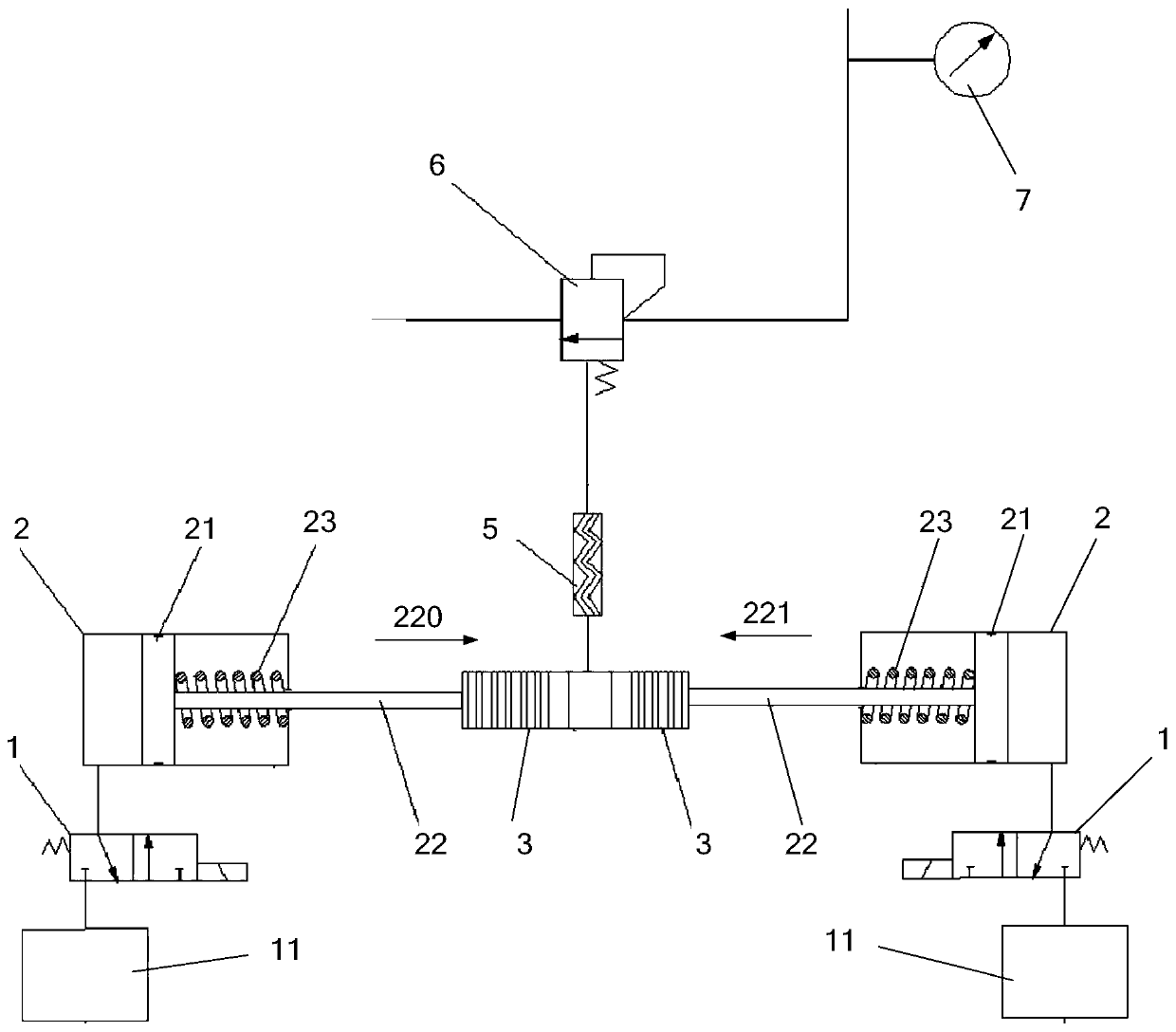

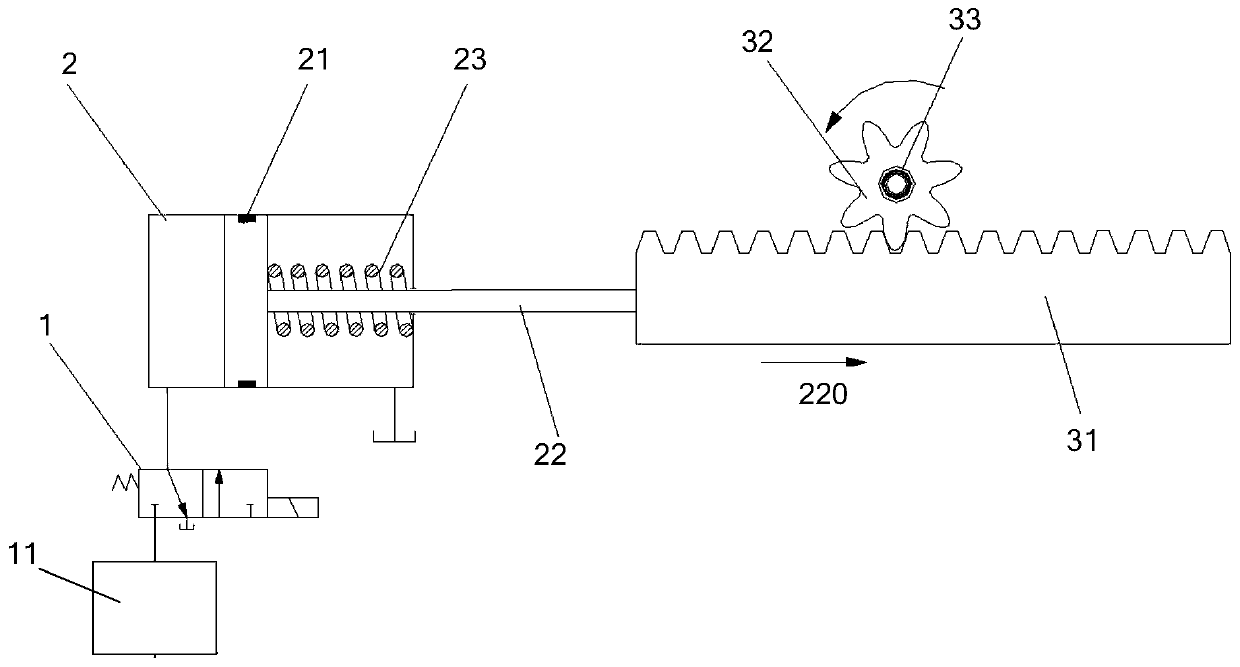

[0047] This embodiment provides a pressure control device, including a power assembly, a transmission assembly and a pressure regulating valve 6 connected in sequence, the transmission assembly includes a two-way clutch, and the two-way clutch has a first transmission state and a second transmission state; the When the two-way clutch is in the first transmission state, when the power assembly moves in the first direction 220, the two-way clutch is engaged to drive the pressure regulating valve 6 to perform pressurization action, and the power assembly moves along the first dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com