A kind of preparation method of lithium-ion battery composite diaphragm

A technology for lithium-ion batteries and composite diaphragms, which is applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of reducing the mechanical strength of the diaphragm, achieve improved safety performance and electrochemical performance, and high lithium ion conductivity. The effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

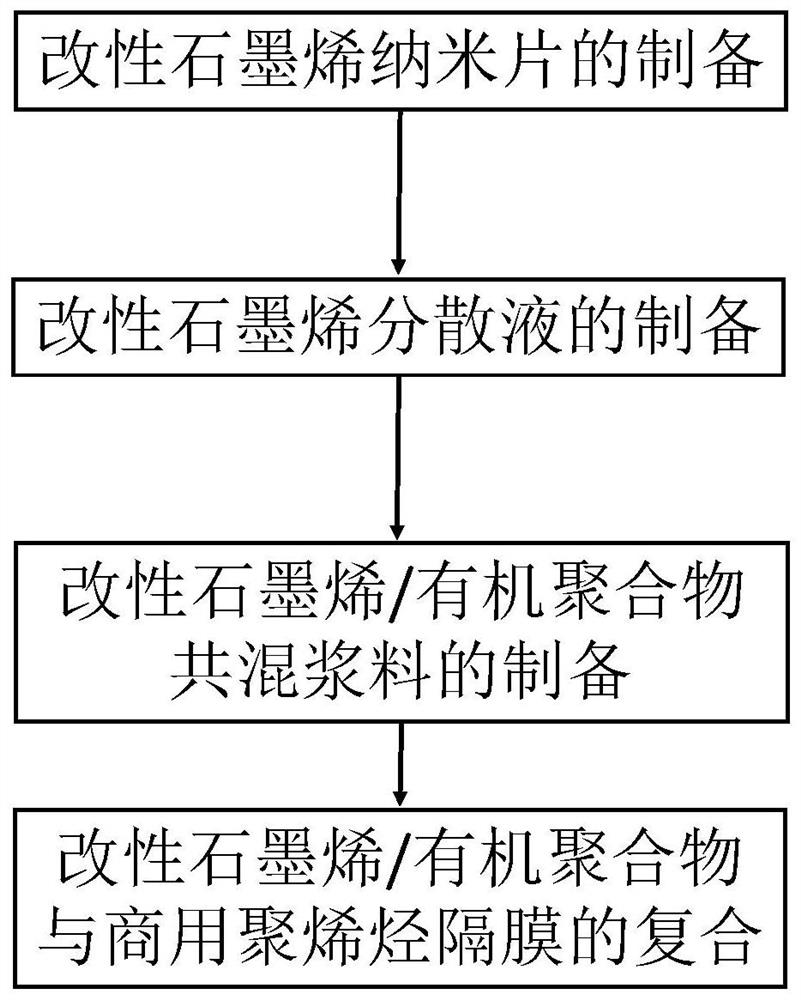

[0024] The preparation method of a kind of lithium-ion battery composite diaphragm that the present invention proposes comprises the following steps:

[0025] S1. Preparation of modified graphene: Weigh 10 mg graphene nanosheets and 100 mg 4-carboxybenzene diazonium salt at normal temperature, put them into 10 mL of 100 mmol / L hypophosphorous acid aqueous solution, stir well, and avoid Leave alone for 24 hours to carry out the modification reaction of graphene, filter and wash the obtained modified graphene aqueous solution, place in an oven and dry at 50°C for 5 hours to obtain modified graphene covalently modified by benzene carboxyl groups;

[0026] S2. Preparation of modified graphene dispersion: add the modified graphene in S1 to 100 mL of N-dimethylacetamide, and ultrasonically disperse for 30 minutes to obtain a modified graphene dispersion;

[0027] S3. Preparation of modified graphene / organic polymer: dissolve polyvinylidene fluoride in N-dimethylacetamide, add modifi...

Embodiment 2

[0030] The preparation method of a kind of lithium-ion battery composite diaphragm that the present invention proposes comprises the following steps:

[0031] S1. Preparation of modified graphene: Weigh 10 mg graphene nanosheets and 100 mg 4-carboxybenzene diazonium salt at normal temperature, put them into 10 mL of 100 mmol / L hypophosphorous acid aqueous solution, stir well, and avoid Leave alone for 24 hours to carry out the modification reaction of graphene, filter and wash the obtained modified graphene aqueous solution, place in an oven and dry at 50°C for 5 hours to obtain modified graphene covalently modified by benzene carboxyl groups;

[0032] S2. Preparation of the modified graphene dispersion: add the modified graphene to 100 mL of N-dimethylacetamide, and disperse it ultrasonically for 30 minutes to obtain the modified graphene dispersion;

[0033] S3. Preparation of modified graphene / organic polymer: dissolve polyvinylidene fluoride in N-dimethylacetamide, add mod...

Embodiment 3

[0036] The preparation method of a kind of lithium-ion battery composite diaphragm that the present invention proposes comprises the following steps:

[0037] S1. Preparation of modified graphene: Weigh 10 mg graphene nanosheets and 100 mg 4-carboxybenzene diazonium salt at normal temperature, put them into 10 mL of 100 mmol / L hypophosphorous acid aqueous solution, stir well, and avoid Leave alone for 24 hours to carry out the modification reaction of graphene, filter and wash the obtained modified graphene aqueous solution, place in an oven and dry at 60°C for 5 hours to obtain modified graphene covalently modified by benzene carboxyl groups;

[0038] S2. Preparation of the modified graphene dispersion: add the modified graphene to 100 mL of N-dimethylacetamide, and disperse it ultrasonically for 50 minutes to obtain the modified graphene dispersion;

[0039] S3. Preparation of modified graphene / organic polymer: dissolve polyvinylidene fluoride in N-dimethylacetamide, add mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com