Filter arrangement, industrial cleaning installation with that filter arrangement and corresponding process

A technology of industrial equipment and filtering device, which is applied in the field of industrial cleaning of workpieces, and can solve problems such as increasing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

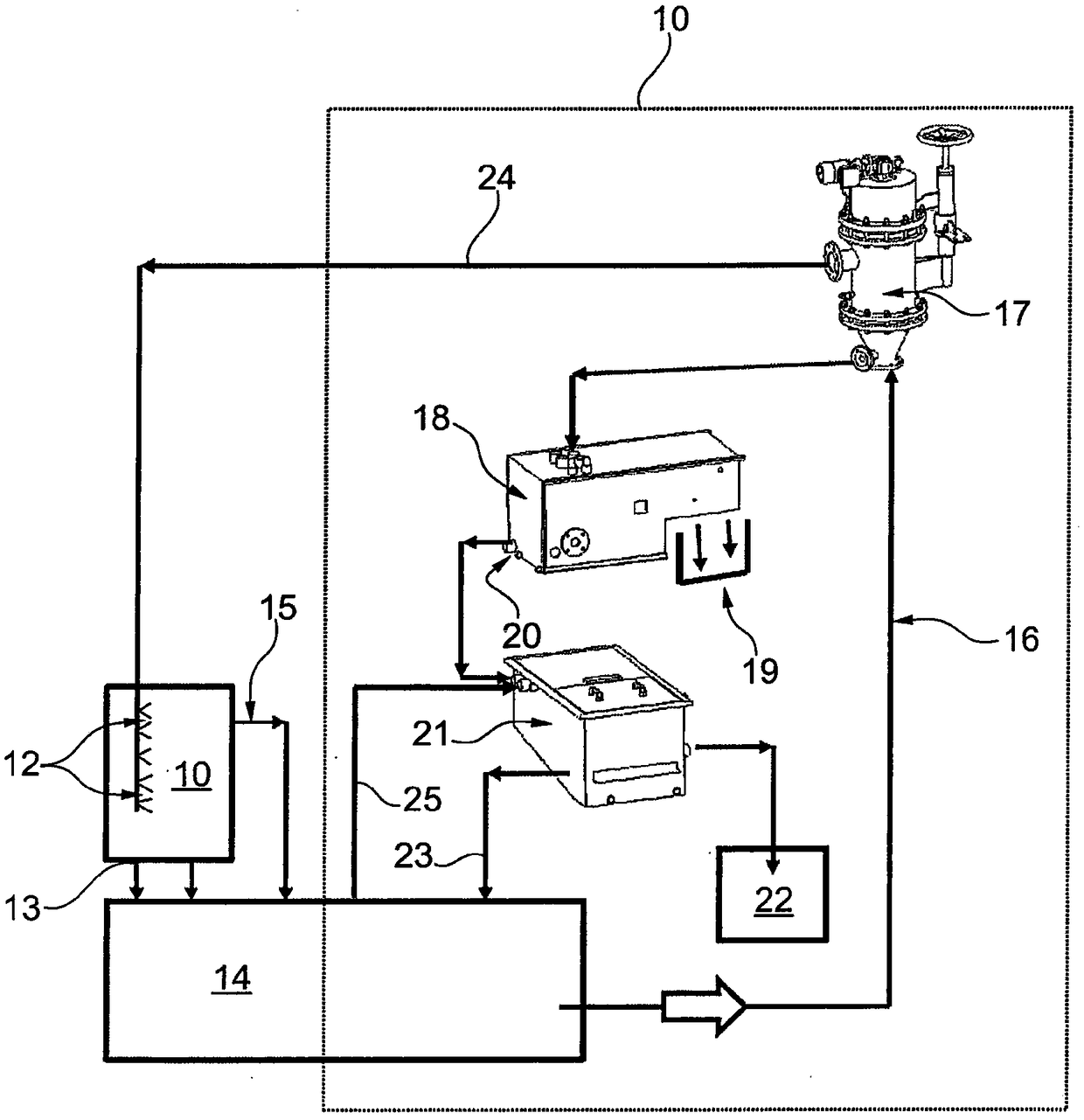

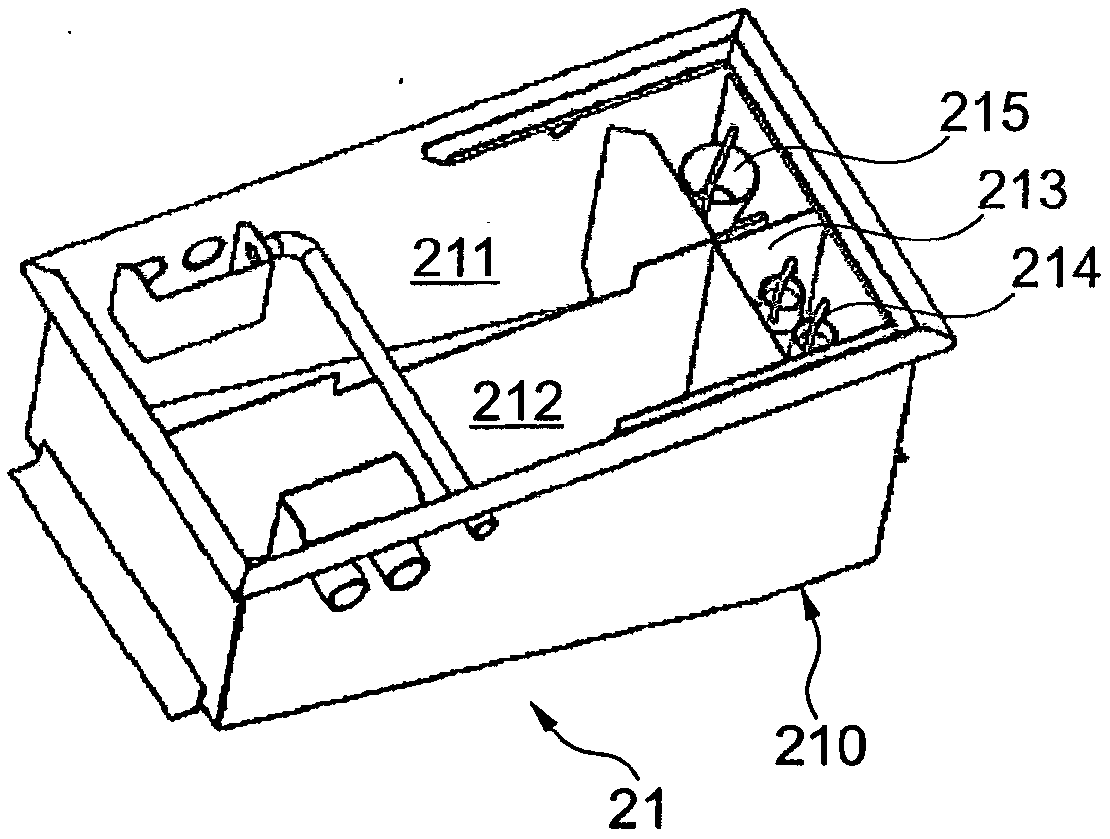

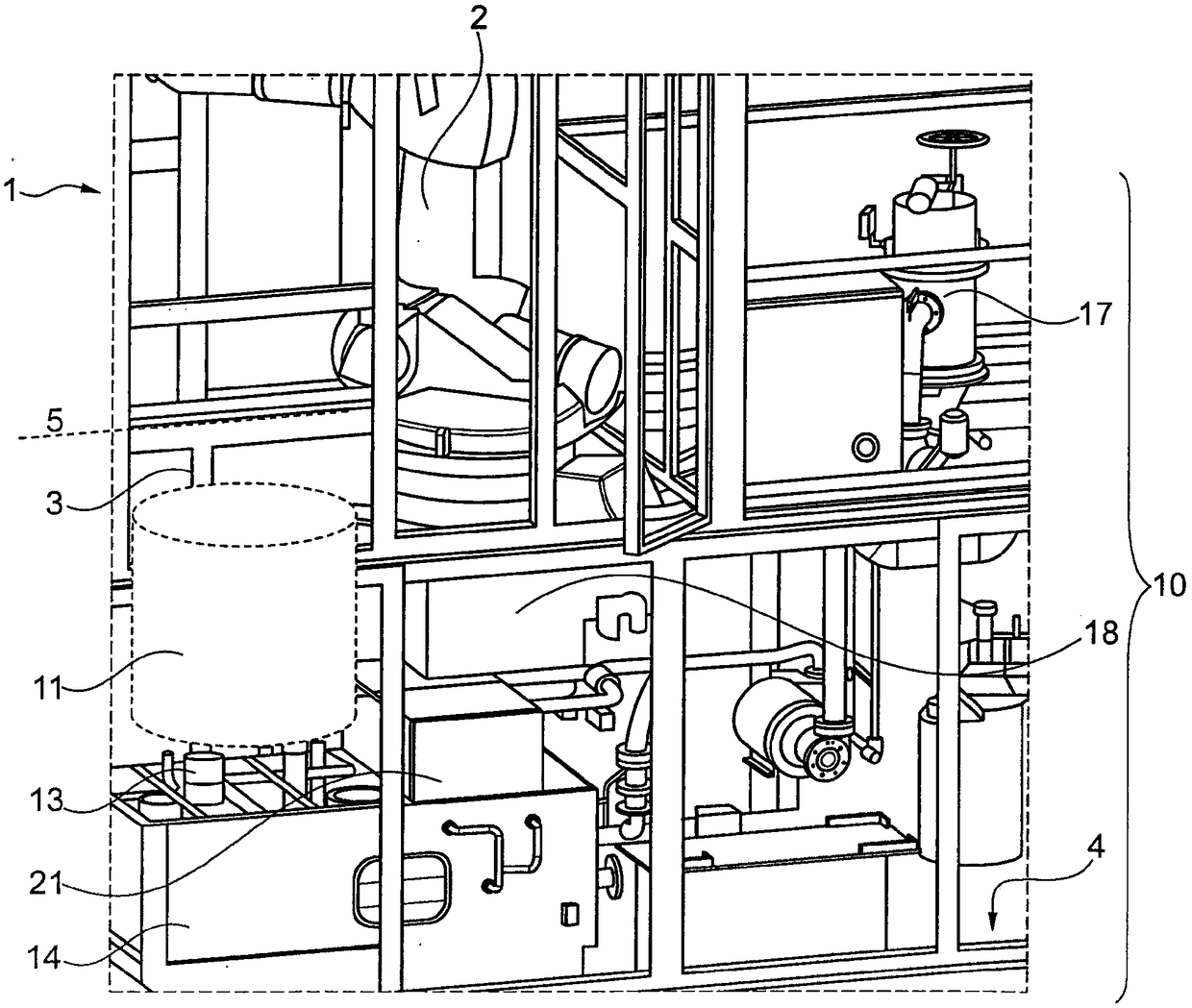

[0028] With reference to a filter device 1 schematically shown for industrial cleaning equipment figure 1, an industrial process for cleaning machined workpieces is first described. The workpiece is, for example, a motor or transmission component, such as a cylinder block, and is machined, for example, by drilling, milling, grinding or turning. Machining may require the use of lubricants, chip removers, rust inhibitors and coolants. Therefore, residues of these liquids and any chips or burrs left on the workpiece must be removed from the part after machining. For this purpose, the workpieces are subjected to a cleaning operation in a cleaning receptacle 11 containing a basin of cleaning liquid. Workpieces can be moved by conveyors or industrial robots (see image 3 ) to the cleaning container 11. A cleaning fluid, which may be water or an aqueous cleaning fluid using water as a solvent, is sprayed onto the workpiece through a plurality of nozzles 12 . Cleaning liquid is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com