Antimicrobial chemically strengthened glass and optimization method for the manufacture thereof

An antibacterial glass, glass technology, applied in the fields of botanical equipment and methods, biocides, plant growth regulators, etc., can solve the problems of reducing visible light, reducing antibacterial properties, and low silver concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

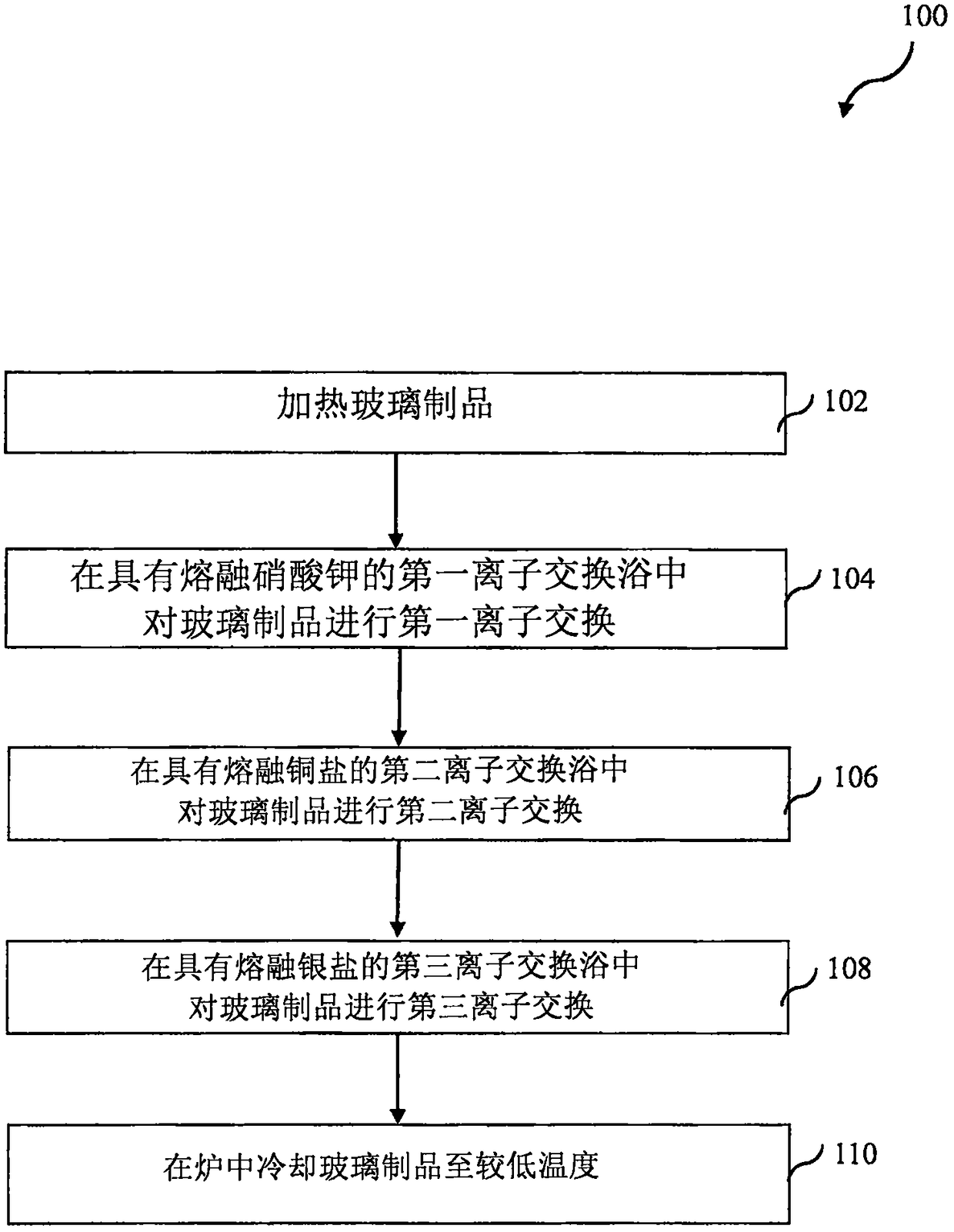

Method used

Image

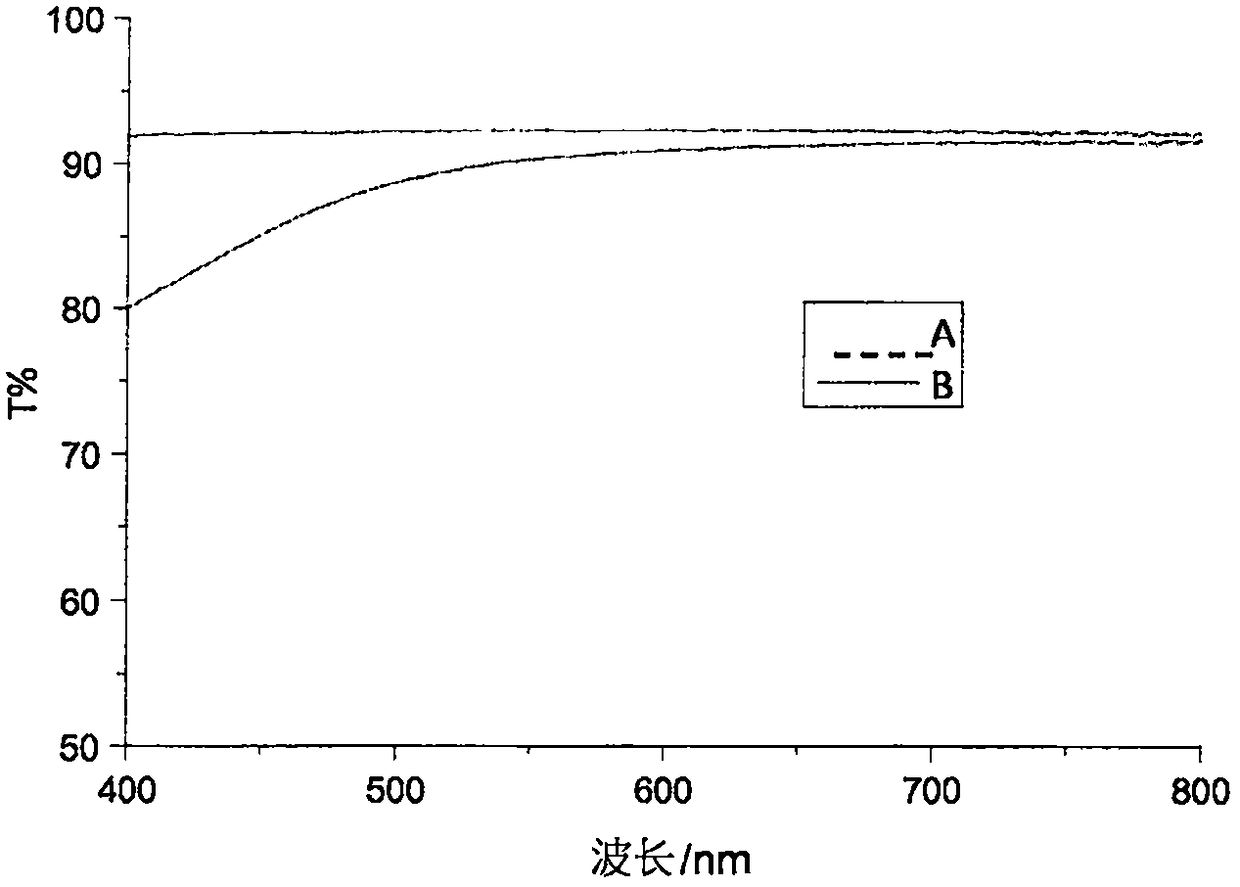

Examples

Embodiment Construction

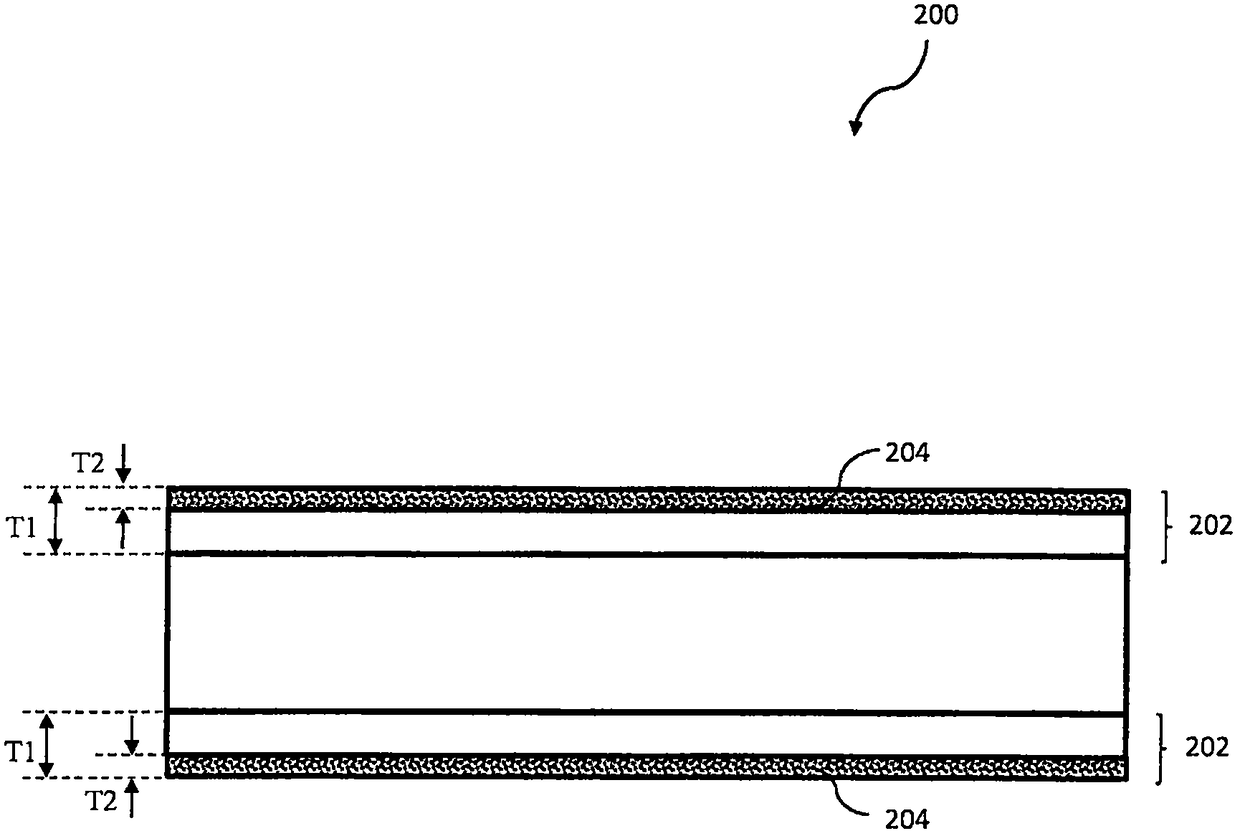

[0012] In several exemplary embodiments, the present invention provides chemically strengthened glass having antimicrobial properties, and methods for making the chemically strengthened glass. The chemically strengthened glass has particular applications as antimicrobial cover glass for electronic displays, touch displays (such as smartphones, tablets, notepads, and automated teller machines), vehicle windshields, and building structures. The chemically strengthened glass can also be used in hand held items that would benefit from antimicrobial properties, such as baby bottles and glassware. As used herein, the term "antibacterial" means a material having one or more of antibiotic, antibacterial, antifungal, antiparasitic, and antiviral properties.

[0013] According to several exemplary embodiments, chemically strengthened glass with antimicrobial properties is made from an ion-exchangeable glass composition comprising:

[0014] Between about 50.0 and about 78.0 weight perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com