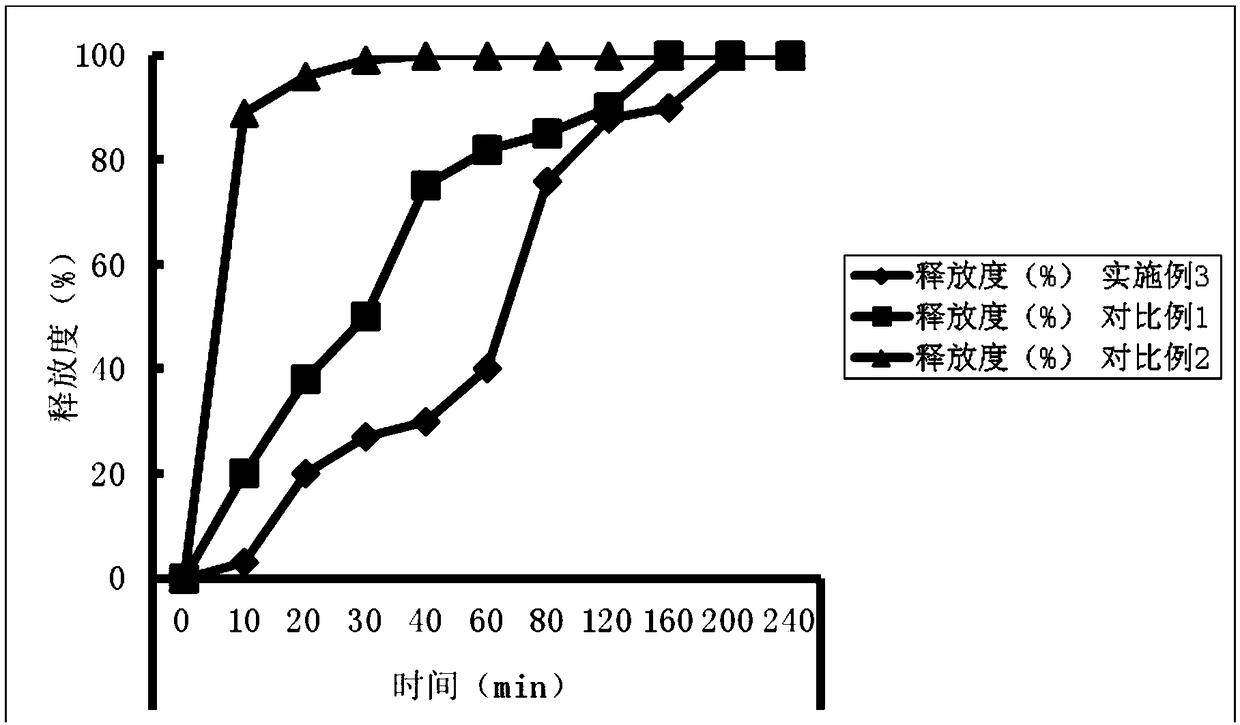

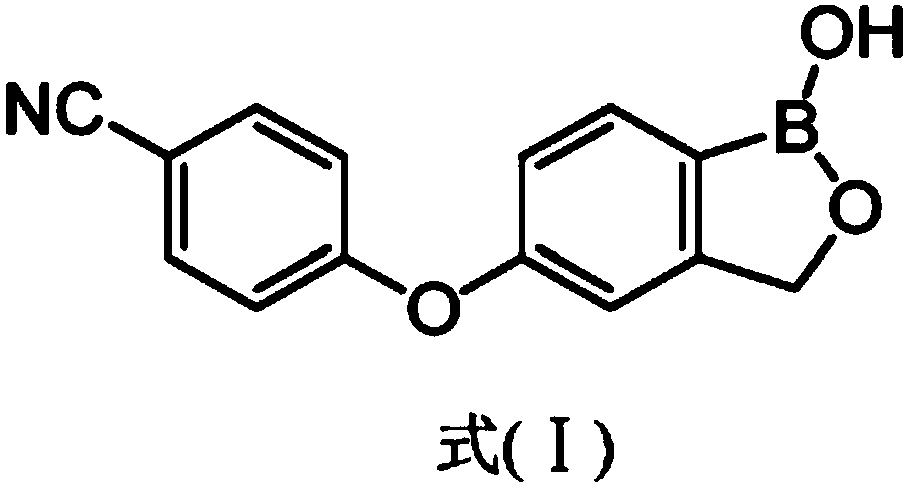

Crisaborole dampness eliminating diuretic sustained-release membrane and preparation method thereof

A technology of criborole and slow-release film, applied in the field of biomedical materials, can solve the problems of not being able to be retained for a long time and being easy to be wiped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. Weigh the following raw materials: criborole 20mg, Sophora flavescens extract 1mg, Sperantosporum extract 1mg, modified starch 4mg, Carbopol 3mg, glycerin 12mg, dissolve the modified starch in deionized water to form a suspension ,spare;

[0026] B, Carbopol and glycerin are added in above-mentioned suspension, mix well;

[0027] C. Add criborole, Sophora flavescens extract and Sperantosporum extract to an appropriate amount of deionized water, and stir evenly;

[0028] D. The products obtained in B and C are mixed and stirred to obtain a uniform viscous substance;

[0029] E. Pour the viscous material obtained in D onto a glass plate, spread it evenly, and dry it in an oven at a temperature of 60°C. Cool, cut, and peel off the film to obtain the crisborole composite health-care slow-release film.

Embodiment 2

[0031] A. Weigh the following raw materials: criborole 35mg, Sophora flavescens extract 3mg, Sperantosporum extract 3mg, modified starch 7mg, Carbopol 6mg, glycerin 20mg, dissolve the modified starch in deionized water to form a suspension ,spare;

[0032] B, Carbopol and glycerin are added in above-mentioned suspension, mix well;

[0033] C. Add criborole, Sophora flavescens extract and Sperantosporum extract to an appropriate amount of deionized water, and stir evenly;

[0034] D. The products obtained in B and C are mixed and stirred to obtain a uniform viscous substance;

[0035] E. Pour the viscous material obtained in D onto a glass plate, spread it evenly, and dry it in an oven at a temperature of 60°C. Cool, cut, and peel off the film to obtain the crisborole composite health-care slow-release film.

Embodiment 3

[0037] A. Weigh the following raw materials: criborole 28mg, Sophora flavescens extract 2mg, Sperantosporum extract 2mg, modified starch 5.5mg, Carbopol 4.5mg, glycerin 16mg, and the modified starch was dissolved in deionized water to form a mixture Suspension, spare;

[0038] B, Carbopol and glycerin are added in above-mentioned suspension, mix well;

[0039] C. Add criborole, Sophora flavescens extract and Sperantosporum extract to an appropriate amount of deionized water, and stir evenly;

[0040] D. The products obtained in B and C are mixed and stirred to obtain a uniform viscous substance;

[0041] E. Pour the viscous material obtained in D onto a glass plate, spread it evenly, and dry it in an oven at a temperature of 60°C. Cool, cut, and peel off the film to obtain the crisborole composite health-care slow-release film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com