Pneumatic type three-parameter Weibull low-frequency ultrasonic atomizing spray nozzle

An ultrasonic atomization, three-parameter technology, applied in the direction of injection device, liquid injection device, etc., to achieve the effect of small stress concentration, small volume, and small metal volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

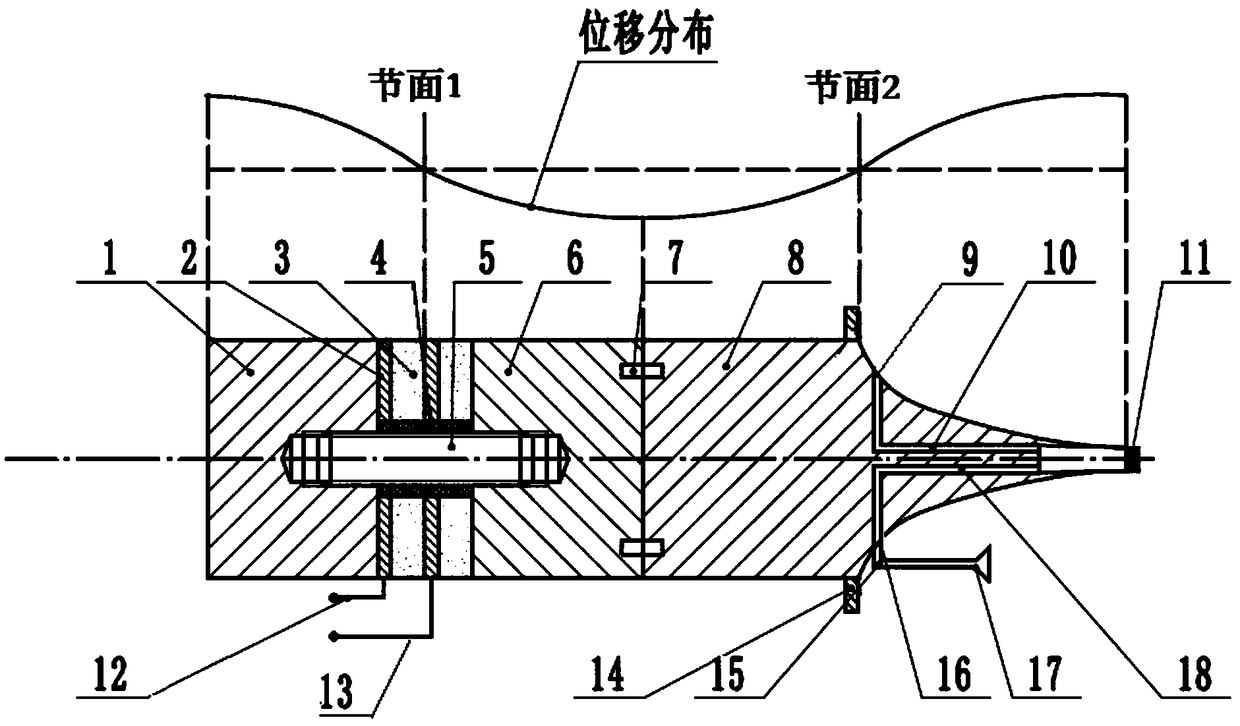

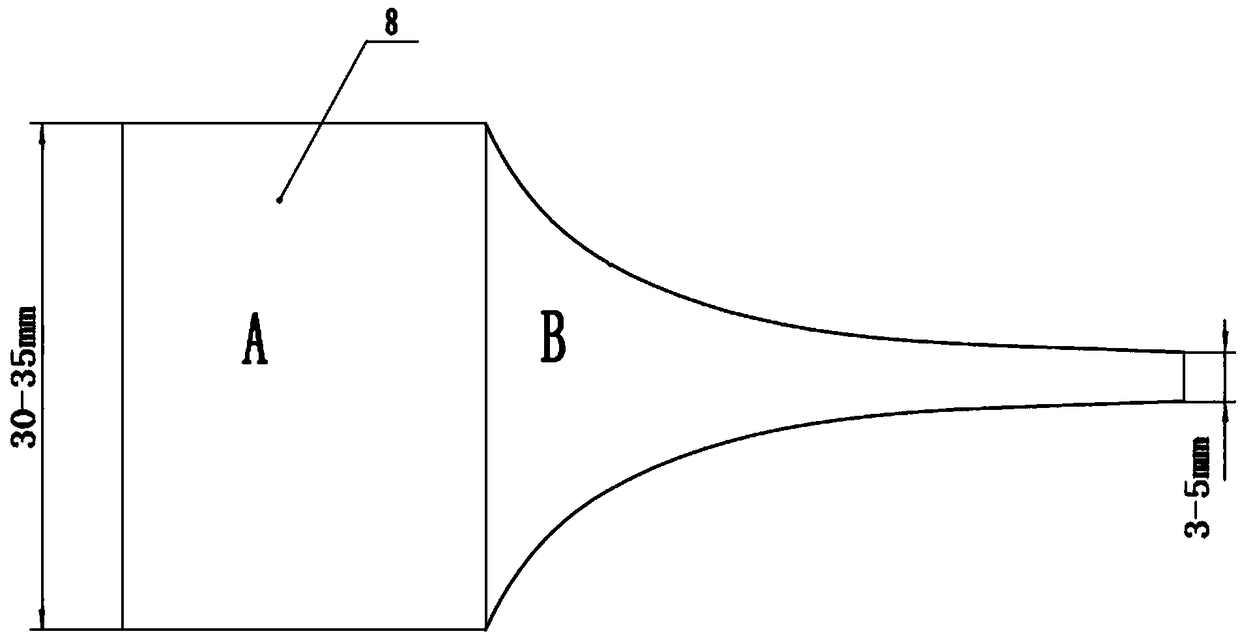

[0031] Such as figure 1 As shown, the air-assisted three-parameter Weibull low-frequency ultrasonic atomizing nozzle includes a rear cover 1, a thin electrode 2, a piezoelectric ceramic 3 and a front cover that are sequentially connected together by fastening bolts 5 from left to right 6. The number of piezoelectric ceramics 3 and thin electrodes 2 is 2, piezoelectric ceramics 3 and thin electrodes 2 are arranged alternately, and insulating rings 4 are arranged between thin electrodes 2 , piezoelectric ceramics 3 and fastening bolts 5 . Several thin electrodes 2 are sequentially connected to the positive pole and the negative pole; the upper half of the piezoelectric ceramic is sequentially connected to the positive pole of the power supply, and the lower half is sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com