Quick casting wax melting device for precise casting production

A technology of melting device and precision casting, applied in casting and molding equipment and other directions, can solve the problems of uneven casting wax, slow melting speed, affecting investment mold production, etc., to speed up melting efficiency, reduce heating temperature, and improve melting The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

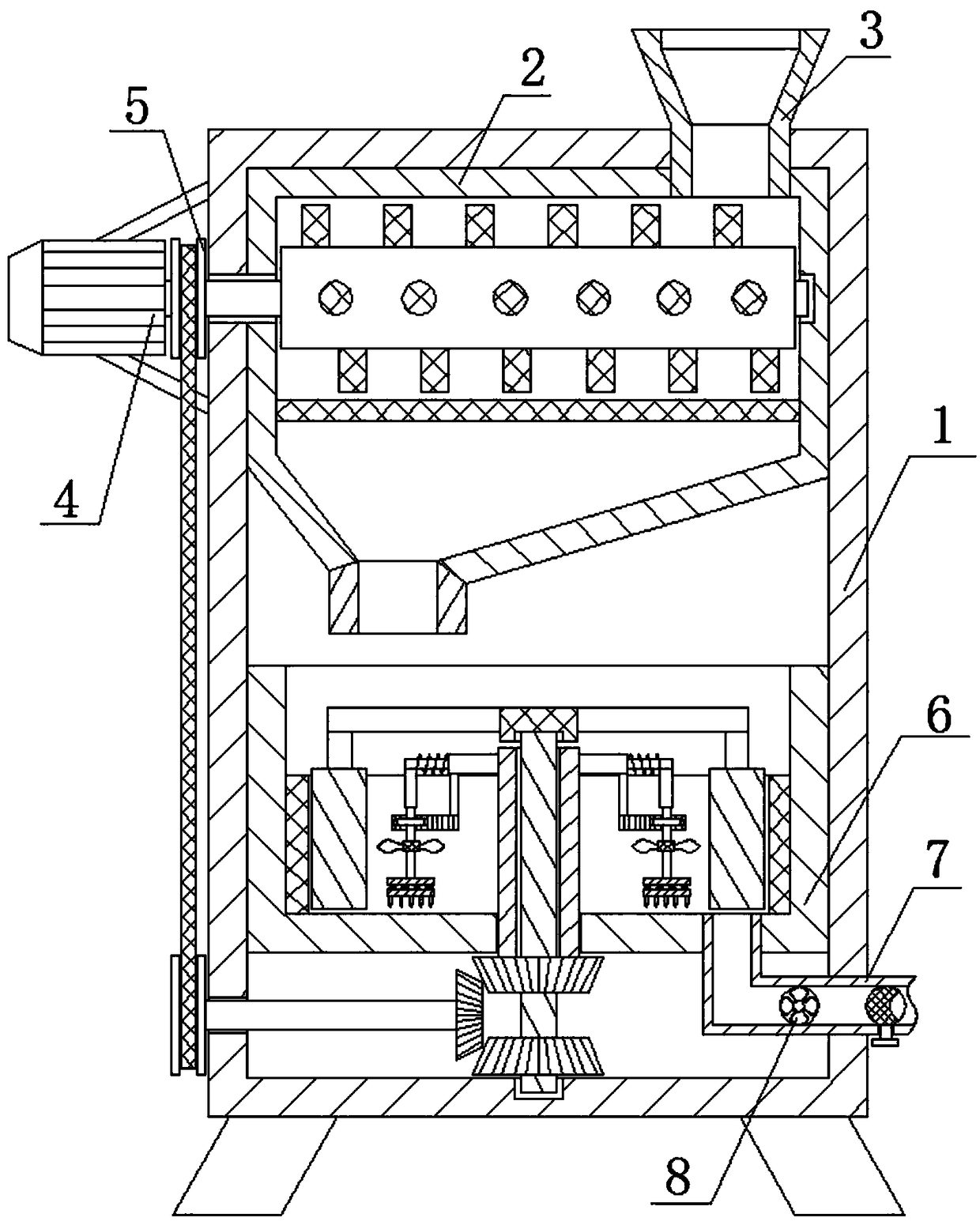

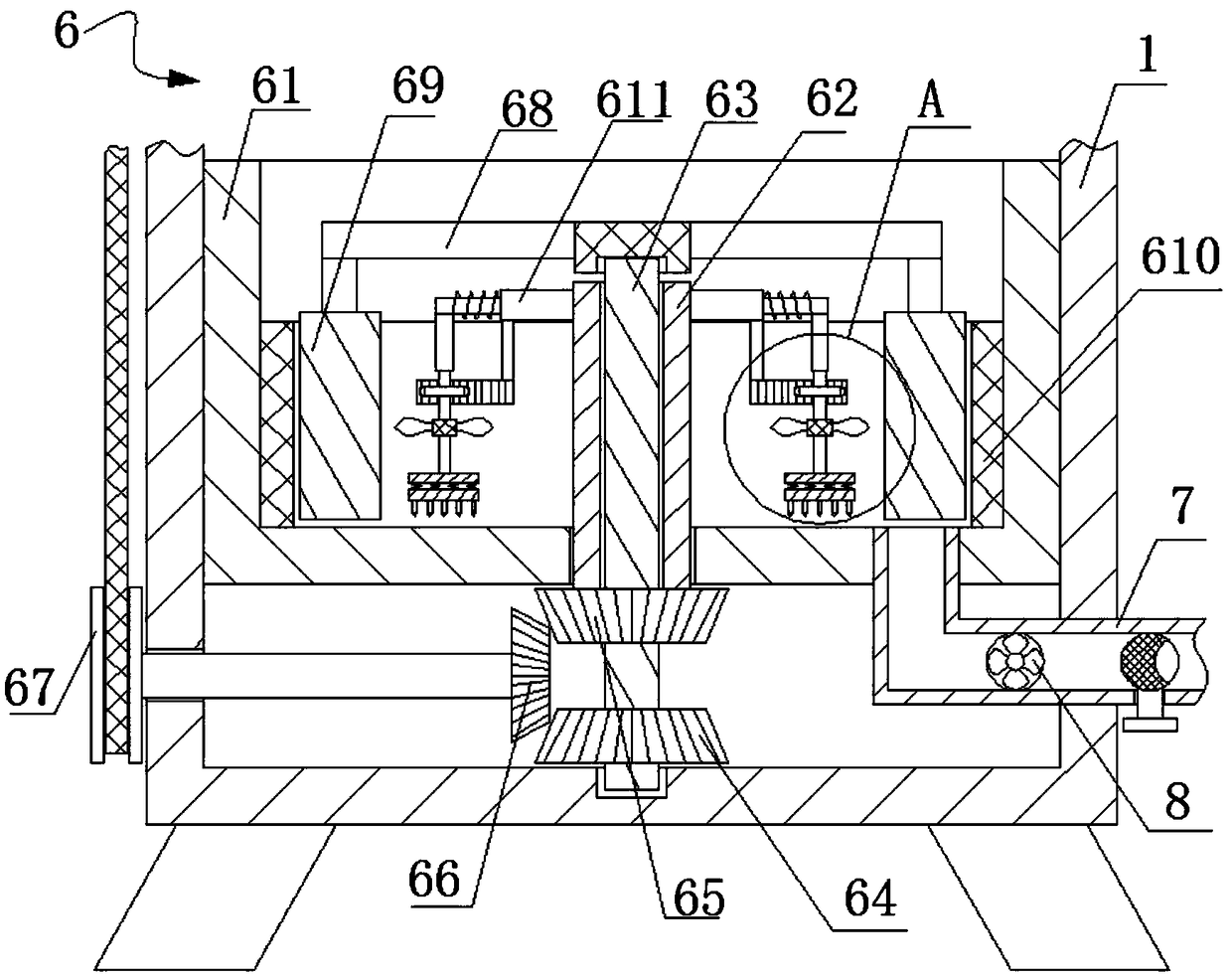

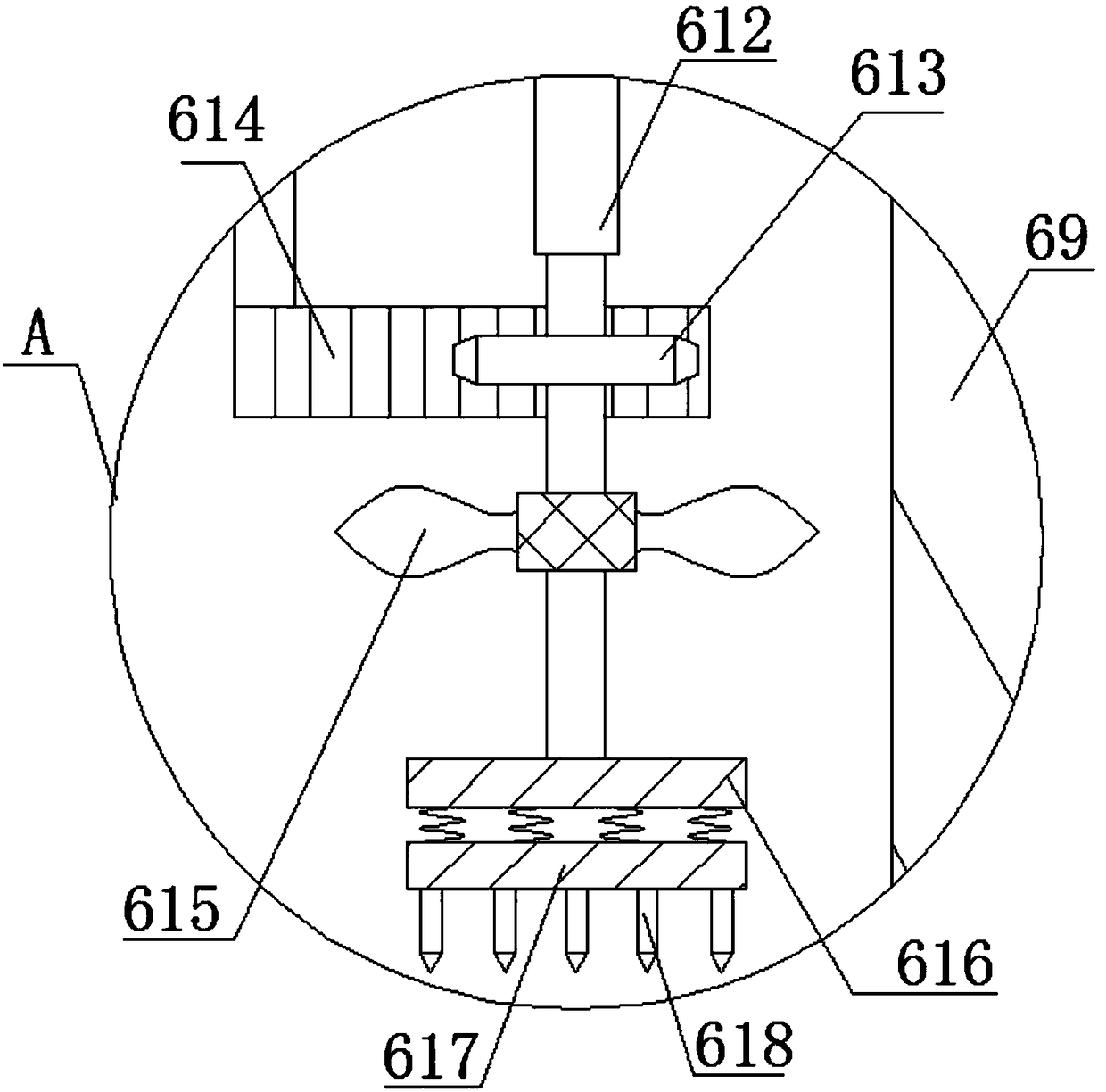

[0038] A casting wax rapid melting device for the production of precision castings, comprising a casing 1, a crushing device 2 and a feed hopper 3, the lower end of the casing 1 is fixedly connected with four supporting legs, and the inner top wall of the casing 1 is fixedly connected with a crushing device 2. The lower end of the feeding hopper 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap