Lead-free solder alloy, preparation method and application thereof, glass assembly

A lead-free solder alloy and alloy technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve problems such as large welding stress, irreversible stress, glass breakage, etc., and achieve small welding stress and excellent performance Superior, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

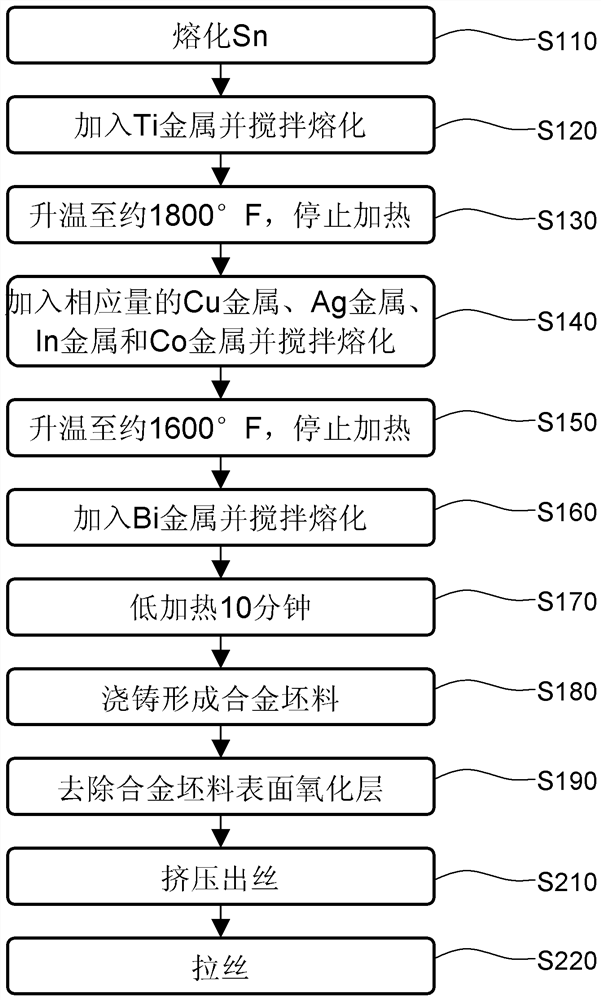

[0058] The components and mass percentages of the lead-free solder alloy of this embodiment are: indium In: 61%, silver Ag: 4.5%, copper Cu: 0.8%, titanium Ti: 0.5%, and the balance is tin and unavoidable impurities .

[0059] The melting point or liquidus temperature of the above composition is 127.24°C, the solidus temperature is 117.64°C, the tensile strength is 34778 PSI, and the Rockwell hardness is 55.

Embodiment 2

[0061] The components and mass percentages of the lead-free solder alloy of this embodiment are: In: 61.8%, silver Ag: 5%, copper Cu: 1.2%, titanium Ti: 1.1%, bismuth Bi: 1.5%, and the balance is tin and unavoidable impurities.

[0062] The melting point or liquidus temperature of the above composition is 133.18°C, the solidus temperature is 121.94°C, the tensile strength is 34791 PSI, and the Rockwell hardness is 55.5.

Embodiment 3

[0064] The components and mass percentages of the lead-free solder alloy of this embodiment are: In: 63%, silver Ag: 7%, copper Cu: 2.2%, titanium Ti: 2.8%, bismuth Bi: 0.5%, cobalt Co: 1.5% %, the balance is tin and unavoidable impurities.

[0065] The melting point or liquidus temperature of the above composition is 138.82°C, the solidus temperature is 127.40°C, the tensile strength is 34812 PSI, and the Rockwell hardness is 56.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com