Self-cooling vertical stone machining tool and manufacturing method thereof

A technology of stone processing and manufacturing methods, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of reduced workpiece processing quality, reduced vertical tool strength, and impact on tool life, etc., to achieve excellent cutting performance , Improving the processing quality of the workpiece and improving the cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention is further described below, but the scope of protection is not limited to the description;

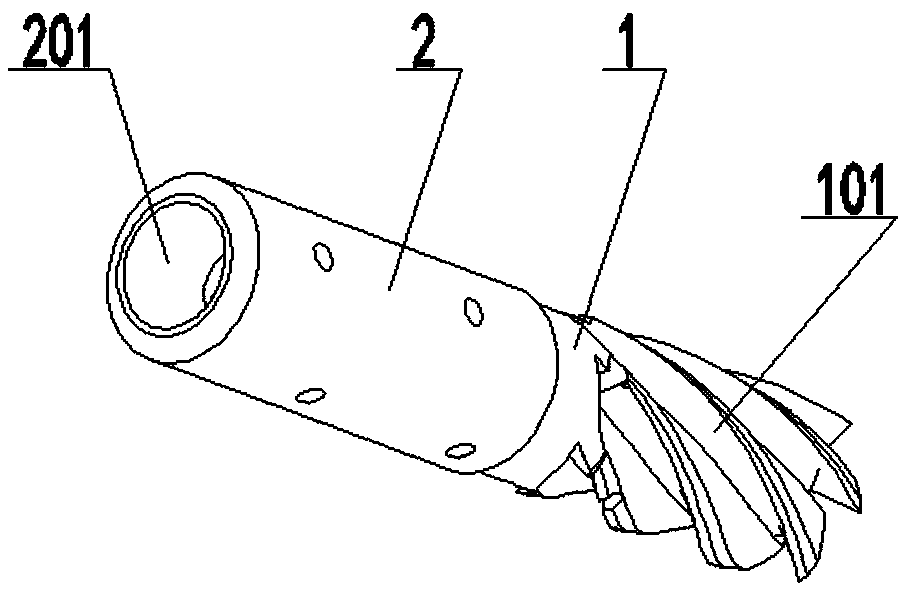

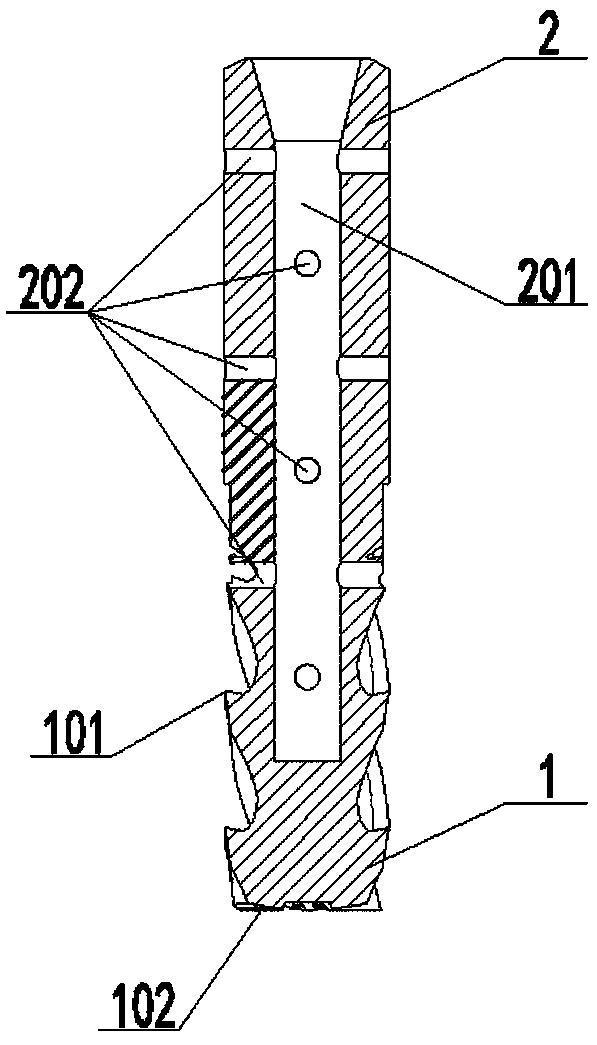

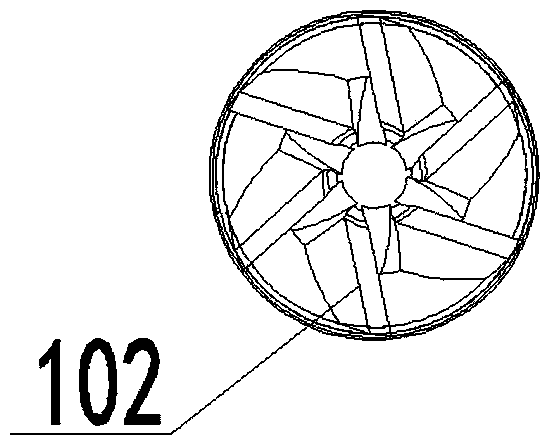

[0029] The invention provides a self-cooling vertical stone processing tool and its manufacturing method, such as figure 1 , figure 2 , image 3 As shown, it includes a cutter body 1 and a handle 2 made of polycrystalline diamond material. The outer peripheral surface of the cutter body 1 is provided with a main cutting edge 101 arranged helically along its central axis, and the end of the main cutting edge 101 is connected to the One end intersects to form a secondary cutting edge 102. The other end of the cutter body 1 is connected to one end of the handle 2. The other end of the handle 2 is provided with a main cooling hole 201 extending along its central axis. The main cooling hole 201 extends deep into the cutter body. 1, the inner wall of the main cooling hole 201 is provided with a plurality of auxiliary cooling holes 202 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com