Surface-nano-crystallized NbSe2 electrode material as well as preparation method and application thereof

A nano-nano technology, applied in chemical instruments and methods, battery electrodes, circuits, etc., can solve the problems of unreported electrode materials, and achieve the effects of market promotion, high discharge platform, and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Surface Nanoized NbSe 2 The preparation method comprises the following steps:

[0027] 1) Add 1.0g of dark gray NbSe 2 The block powder was added to 30mL of deionized water, followed by 10 minutes of ultrasonication and vigorous stirring for 15 minutes to fully disperse and dissolve the block powder;

[0028] 2) Transfer the suspension in step 1) to a microwave synthesizer, first keep it warm at 100°C for 5 minutes, then continue to heat up to 180°C and keep it warm for 12 hours. The heating rate of these two processes is 10°C / min;

[0029] 3) Wash the sample obtained in step 2) three times with water and one time with alcohol, and dry it in vacuum at 80°C to obtain the final black product NbSe 2 -M-12h.

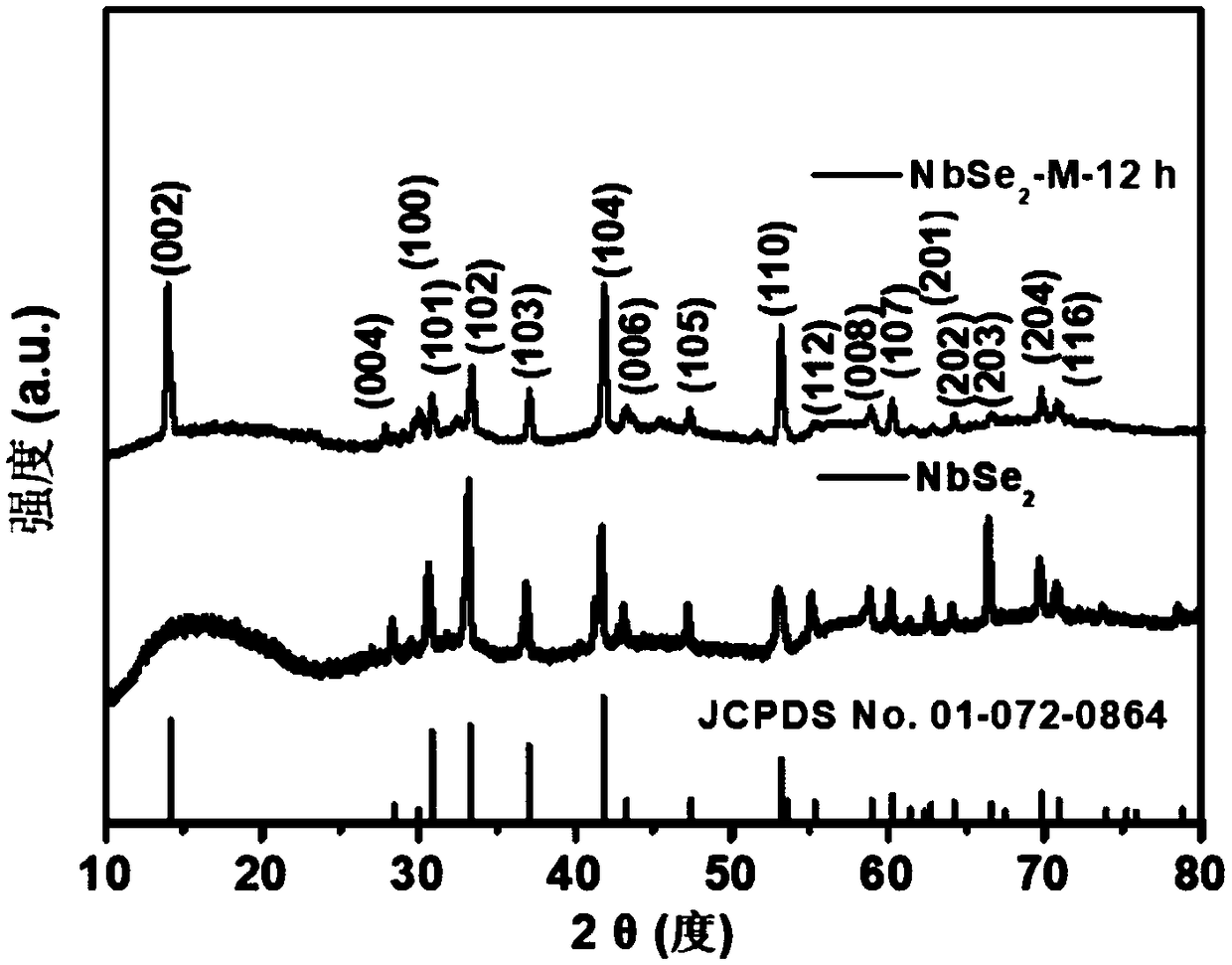

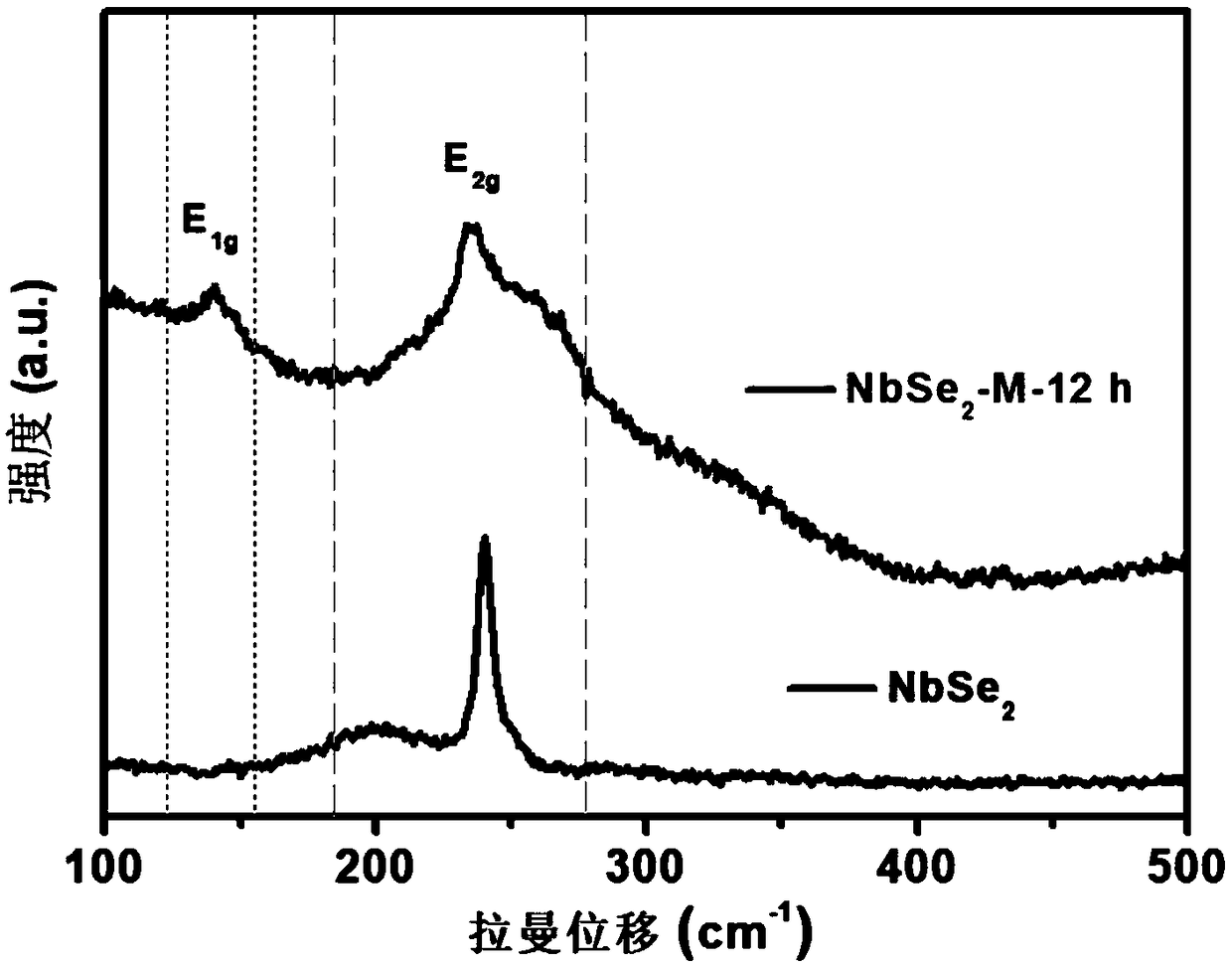

[0030] With the product NbSe of this example 2 -M-12h as an example, its structure was determined by X-ray diffractometer. like figure 1 As shown, the X-ray diffraction pattern (XRD) shows that the original and microwave-treated samples are all hexagonal phase N...

Embodiment 2

[0034]Surface Nanoized NbSe 2 The preparation method comprises the following steps:

[0035] 1) Add 0.9g of dark gray NbSe 2 The block powder was added to 30mL of deionized water, followed by 10 minutes of ultrasonication and vigorous stirring for 15 minutes to fully disperse and dissolve the block powder;

[0036] 2) Transfer the suspension in step 1) to a microwave synthesizer, first heat it at 100°C for 5 minutes, then continue to heat up to 180°C and hold it for 11.5 hours. The heating rate of these two processes is 10°C / min;

[0037] 3) Wash the sample obtained in step 2) three times with water and one time with alcohol, and dry it in vacuum at 80°C to obtain the final black product NbSe 2 -M-12h.

[0038] With the surface nano-sized NbSe obtained in this example 2 For example, under the current density of 200 and 500mA / g, the initial capacity can reach 90 and 45mAh / g.

Embodiment 3

[0040] Surface Nanoized NbSe 2 The preparation method comprises the following steps:

[0041] 1) Add 1.0g of dark gray NbSe 2 The block powder was added to 32mL of deionized water, followed by 10 minutes of ultrasonication and vigorous stirring for 15 minutes to fully disperse and dissolve the block powder;

[0042] 2) Transfer the suspension in step 1) to a microwave synthesizer, first keep it warm at 100°C for 5 minutes, then continue to heat up to 180°C and keep it warm for 12 hours. The heating rate of these two processes is 10°C / min;

[0043] 3) Wash the sample obtained in step 2) three times with water and one time with alcohol, and dry it in vacuum at 80°C to obtain the final black product NbSe 2 -M-12h.

[0044] With the surface nano-sized NbSe obtained in this example 2 For example, under the current density of 200 and 500mA / g, the initial capacity can reach 92 and 48mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com