Recycling method of nickel cobalt lithium manganate battery, regenerated nickel cobalt lithium manganate material and application

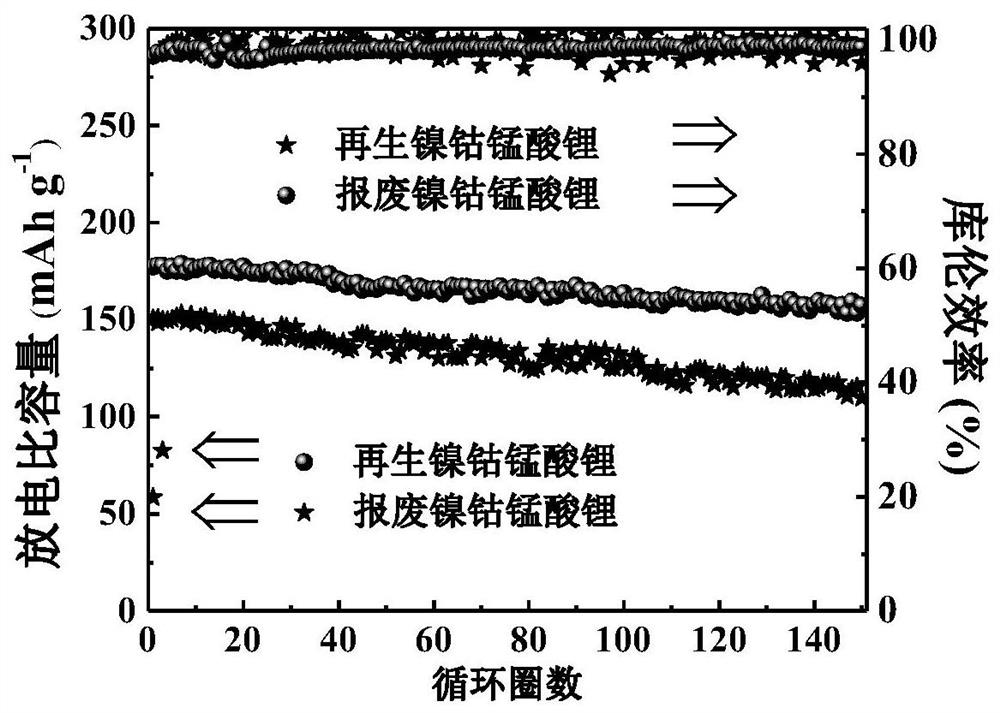

A nickel-cobalt-lithium-manganese-oxide and recovery method technology, applied in the application of regenerated nickel-cobalt-lithium-manganese-oxide materials, recycling of nickel-cobalt-lithium-manganate batteries, and the field of regenerated nickel-cobalt-lithium-manganate materials, can solve the complicated precipitation process of metal elements , can not fully achieve the expected effect, consume a large amount of electric energy and other problems, to achieve stable cycle performance, improve leaching effect, and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The nickel cobalt lithium manganate battery recycling method is characterized in that, comprising the following steps:

[0044] (1) Discharge the waste nickel-cobalt lithium manganate battery for 1 day in NaCl solution, and then disassemble it to obtain positive electrode sheet, negative electrode sheet, aluminum shell, electrolyte and separator in a sealed box; soak the positive electrode sheet in The black powder was obtained in the NaOH solution for 5 hours, and then the black powder was dried, ball milled and sieved to obtain the positive electrode material powder, and the particle size of the positive electrode powder material was 300 mesh.

[0045] (2) Calcining the obtained positive electrode material powder in an air atmosphere at 500° C. for 5 hours to remove impurities such as binder and acetylene black on the surface of the powder.

[0046] (3) The positive electrode material powder after the above-mentioned removal of impurities is added in the round bottom ...

Embodiment 2

[0049] The nickel cobalt lithium manganate battery recycling method is characterized in that, comprising the following steps:

[0050] (1) Discharge the waste nickel-cobalt lithium manganate battery for 1 day in NaCl solution, and then disassemble it to obtain positive electrode sheet, negative electrode sheet, aluminum shell, electrolyte and separator in a sealed box; soak the positive electrode sheet in The black powder was obtained in the NaOH solution for 6 hours, and then the black powder was dried, ball milled and sieved to obtain the positive electrode material powder, and the particle size of the positive electrode material powder was 400 mesh.

[0051] (2) Calcining the obtained positive electrode material powder in an air atmosphere at 600° C. for 5 hours to remove impurities such as binder and acetylene black on the surface of the powder.

[0052] (3) The positive electrode material powder after the above-mentioned removal of impurities is added in a round bottom fl...

Embodiment 3

[0055] The nickel cobalt lithium manganate battery recycling method is characterized in that, comprising the following steps:

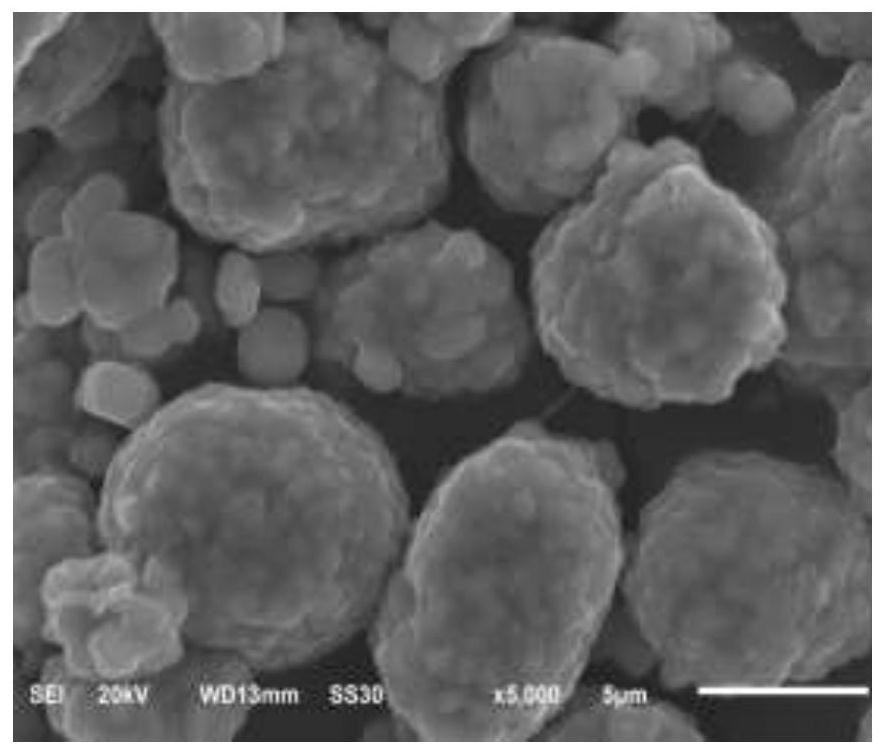

[0056] (1) Discharge the waste nickel-cobalt lithium manganate battery for 1 day in NaCl solution, and then disassemble it to obtain positive electrode sheet, negative electrode sheet, aluminum shell, electrolyte and separator in a sealed box; soak the positive electrode sheet in The black powder was obtained in NaOH solution for 7h, and then the black powder was dried, ball milled and sieved to obtain the positive electrode material powder. The particle size of the positive electrode material powder was 500 mesh, and its SEM electron microscope picture figure 1 shown.

[0057] (2) Calcining the obtained positive electrode material powder in an air atmosphere at 700° C. for 5 hours to remove impurities such as binder and acetylene black on the surface of the powder.

[0058] (3) The positive electrode material powder after the above-mentioned removal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com