Metal carbide catalyst, preparation method thereof and application thereof in lithium-oxygen battery

A metal carbide, lithium-oxygen battery technology, used in battery electrodes, fuel cell-type half-cells, primary battery-type half-cells, circuits, etc., to achieve the effects of low overpotential, excellent stability, and excellent rate capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

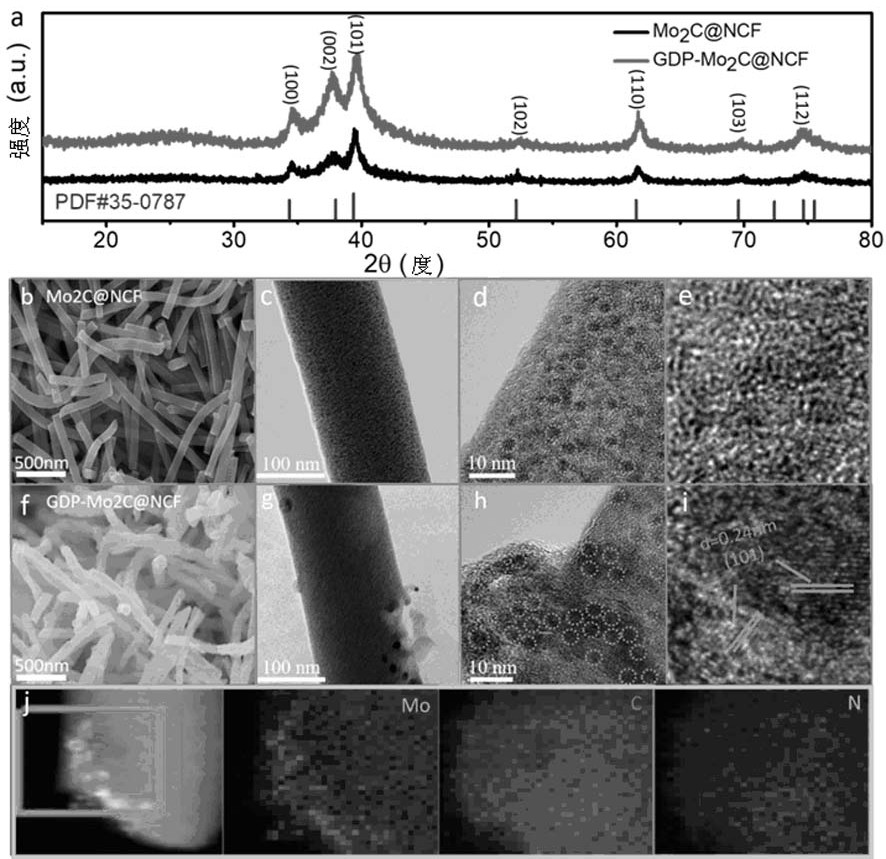

[0020] Dissolve 0.5 g polyvinylpyrrolidone (PVP) and 0.5 g polyacrylonitrile (PAN, MW = 150000) in 10 ml N,N-dimethylformamide (DMF), then add 1.0 mmol ammonium molybdate (H 8 MON 2 o 4 ), stirred to obtain the electrospinning precursor solution; the prepared precursor solution was sucked into a plastic syringe (10ml) with a stainless steel nozzle (inner diameter of 0.4 mm) for electrospinning, during the electrospinning preparation process, the needle A high voltage of 12-15 kV was applied between the tip and the aluminum foil collector, while the distance between the tip and the receiver was controlled to be 10 cm, and the injection speed of the syringe was 0.05 mm min -1 After spinning, the obtained fabric was taken out from the collector and transferred to a vacuum oven maintained at 60 °C for 12 h, then the dried spun fabric was stably calcined in air at 200 °C for 1 h, and then In high purity N 2 Calcined at a high temperature of 800 °C for 2 h in a tube furnace used ...

Embodiment 2

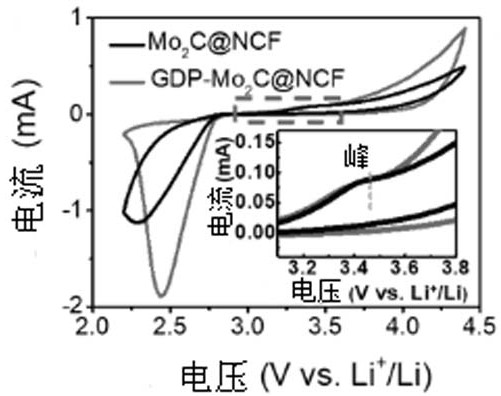

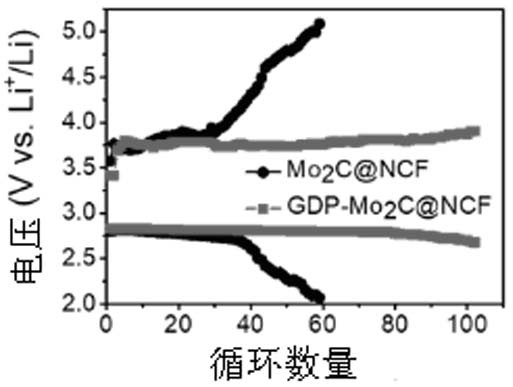

[0024] Type 2032 LOBs were routinely assembled to evaluate catalyst activity after glow discharge plasma treatment. The electrocatalyst (GDP-Mo2C@NCF) of Example 1, carbon black (super P) and polyvinylidene fluoride binder were mixed in a weight ratio of 70:20:10, and then coated on carbon paper to prepare a conventional working electrode. Among them, the electrocatalyst loading on carbon paper is 0.6-0.8 mg / cm2; the electrolyte is 1M lithium bis(carbon trioxide) sulfonimide (LiTFSI), in dimethyl sulfoxide; 2032 type battery LOBs, including lithium Metal anode (15 mm diameter), glass fiber separator (gfc, 19 mm diameter) immersed in electrolyte, and cathode (working electrode, 14 mm diameter), were assembled in a glove box with high-purity argon.

[0025] The electrochemical performance of the assembled battery was routinely tested in a high-purity oxygen airtight container, the constant current discharge and charge test was carried out on the LAND BT 2000 battery test system,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com