A kind of composite concrete anti-cracking agent and preparation method thereof

A concrete and anti-cracking agent technology, applied in the field of building materials, can solve the problems of not achieving the expected effect, poor film-forming effect, and curing agent damage, etc., and achieve the effect of increasing compactness, compact structure, and reducing water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

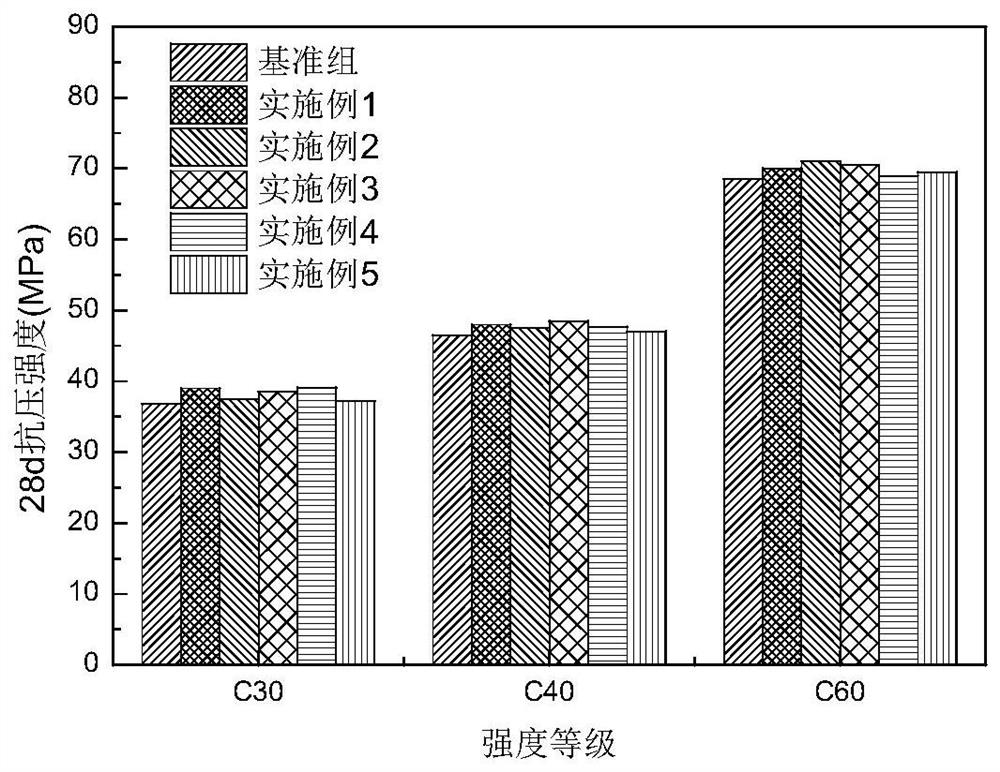

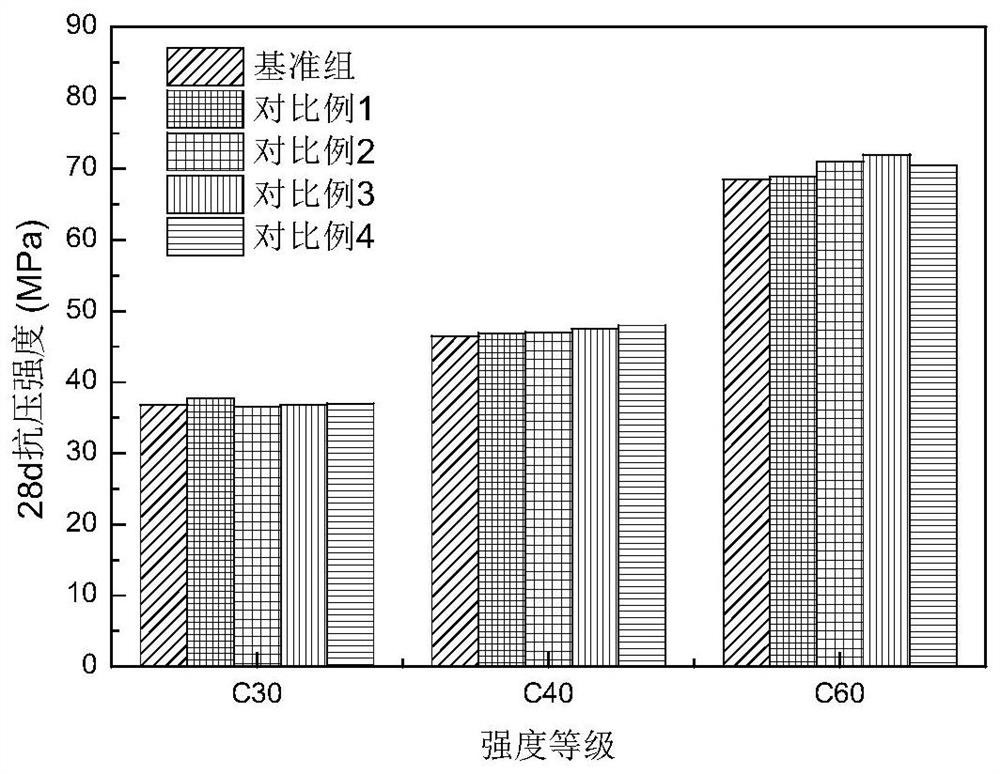

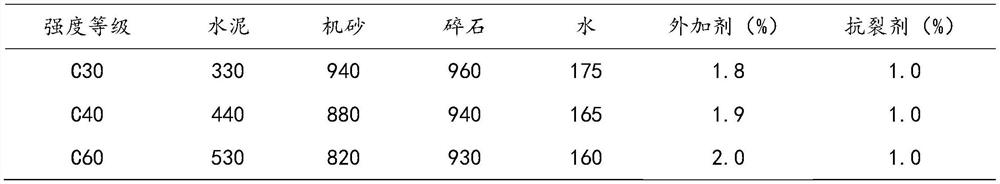

[0037] The composite concrete anti-cracking agent described in embodiments 1 to 5, its raw material ratio is shown in Table 1, and the test results are shown in Table 4 and figure 1 Shown, its preparation method comprises the steps:

[0038] 1) Take each raw material according to the ratio of raw materials in Table 1;

[0039] 2) Slowly add the weighed polyvinyl alcohol into cold water at about 20°C to fully swell, disperse and wait for the overflow of volatile substances. The stirring speed is 70-100r / min, and then the temperature is raised to 95°C by means of water bath heating. ℃ to accelerate the dissolution, and keep warm for 2 to 2.5 hours until the solution no longer contains tiny particles, and then pass through a 28-mesh stainless steel mesh to filter impurities, then cool down to room temperature for use.

[0040] 3) Stir the weighed polypropylene glycol, VAE emulsion, and water at room temperature under the condition of 150-200 r / min to obtain a mixed solution A fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com