A cement-based high-strength non-dispersible grouting material

A grouting material and cement-based technology, applied in the field of cement-based materials, can solve the problems of incomplete surface structure strength, weak water impact resistance, and easy loss of surface slurry, so as to avoid surface quality deterioration and strong water impact resistance , the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

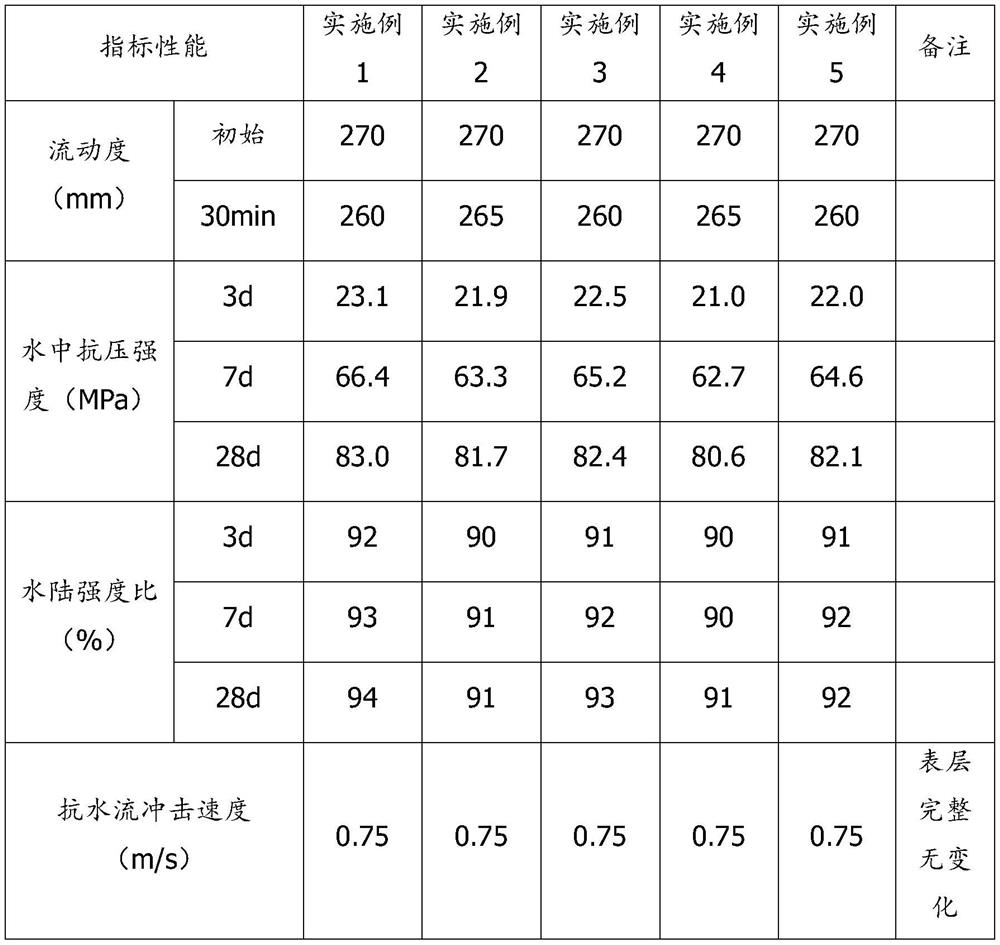

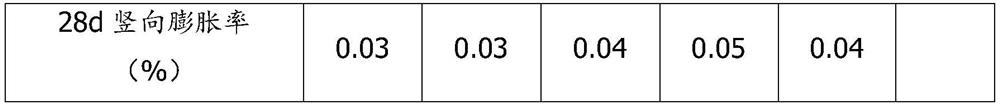

Examples

Embodiment 1

[0039] The cement-based high-strength underwater non-dispersible grouting material of the embodiment of the present invention is prepared by mixing the following components by weight:

[0040] Portland cement: 380 parts;

[0041] Superfine Portland cement: 80 parts;

[0042] Calcium sulfoaluminate cement: 40 parts;

[0043] Superfine fly ash: 50 parts

[0044] 6 mesh ~ 140 mesh quartz sand: 450 parts

[0045] Water reducer: 3.5 parts;

[0046] Flocculant: 7 parts;

[0047] Water: 170 parts.

[0048] The Portland cement mentioned above is 52.5 grade I type Portland cement.

[0049] The superfine Portland cement mentioned above has a specific surface area of 800m 2 / kg-900m 2 / kg, 28d Portland cement with a strength grade of 52.5MPa-62.5MPa.

[0050]The above-mentioned calcium sulfoaluminate cement is CSA cement produced by Tangshan Polar Bear Building Materials Co., Ltd., with a 28d strength grade of 92.5MPa.

[0051] The particle size distribution of the above ultr...

Embodiment 2

[0061] The cement-based high-strength underwater non-dispersible grouting material of the embodiment of the present invention is prepared from the following components by weight:

[0062] Portland cement: 400 parts;

[0063] Superfine Portland cement: 60 parts;

[0064] Calcium sulfoaluminate cement: 40 parts;

[0065] Superfine fly ash: 45 parts

[0066] 6 mesh to 140 mesh quartz sand: 455 parts

[0067] Water reducer: 3.0 parts;

[0068] Flocculant: 6 parts;

[0069] Water: 175 parts.

[0070] The Portland cement mentioned above is 52.5 grade I type Portland cement.

[0071] The superfine Portland cement mentioned above has a specific surface area of 900m 2 / kg-1000m 2 / kg, 28d Portland cement with a strength grade of 72.5MPa-82.5MPa.

[0072] The above-mentioned calcium sulfoaluminate cement is CSA cement produced by Tangshan Polar Bear Building Materials Co., Ltd., with a 28d strength grade of 92.5MPa.

[0073] The particle size distribution of the above ultraf...

Embodiment 3

[0083] The cement-based high-strength underwater non-dispersible grouting material of the embodiment of the present invention is prepared from the following components by weight:

[0084] Portland cement: 340 parts;

[0085] Superfine Portland cement: 70 parts;

[0086] Calcium sulfoaluminate cement: 50 parts;

[0087] Superfine fly ash: 50 parts

[0088] 6 mesh ~ 140 mesh quartz sand: 490

[0089] Water reducing agent: 4 parts;

[0090] Flocculant: 8 parts;

[0091] Water: 170 parts.

[0092] The Portland cement mentioned above is 52.5 grade I type Portland cement.

[0093] The superfine Portland cement mentioned above has a specific surface area of 1000m 2 / kg-1100m 2 / kg, 28d Portland cement with a strength grade of 82.5MPa-92.5MPa.

[0094] The above-mentioned calcium sulfoaluminate cement is CSA cement produced by Tangshan Polar Bear Building Materials Co., Ltd., with a 28d strength grade of 92.5MPa.

[0095] The particle size distribution of the above ultrafi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com