Polyether composition for preparing reticulated polyurethane foam and application thereof

A technology of polyurethane foam and composition, which is applied in the field of high molecular polymer material preparation, to achieve the effects of reducing equipment finished products, good storage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

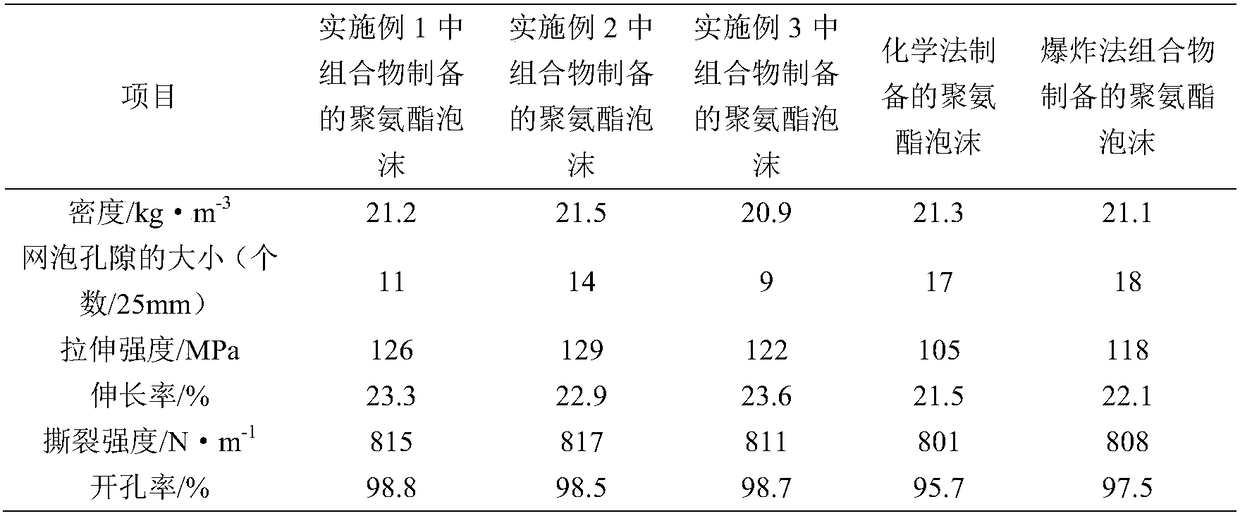

Examples

example 1

[0035] The polyether composition for preparing reticulated polyurethane foam consists of the following components in parts by weight:

[0036] Polyether polyol A: 70 parts,

[0037] Polyether polyol B: 15 parts,

[0038] Polyether polyol C: 3 parts,

[0039] Polymer polyol D: 15 parts,

[0040] Foam stabilizer: 1.2 parts,

[0041] Amine catalyst: 0.4 parts,

[0042] Gel catalyst: 0.32 parts.

[0043] Among them, polyether polyol A is prepared by polyaddition reaction with glycerin as an initiator, and is a random copolyether of propylene oxide and ethylene oxide with a propylene oxide content of 68% and a number average molecular weight of 6000; polyether Polyol B is prepared by polyaddition reaction with propylene glycol as the initiator, and is a propylene oxide-ethylene oxide block copolyether with an ethylene oxide content of 32% and a number average molecular weight of 2000; polyether polyol Alcohol C is prepared by addition polymerization with n-butanol as the init...

example 2

[0049] The polyether composition for preparing reticulated polyurethane foam consists of the following components in parts by weight:

[0050] Polyether polyol A: 65 parts,

[0051] Polyether polyol B: 25 parts,

[0052] Polyether polyol C: 3.8 parts,

[0053] Polymer polyol D: 10 parts,

[0054] Foam stabilizer: 1.7 parts,

[0055] Amine catalyst: 0.45 parts,

[0056] Gel catalyst: 0.2 parts.

[0057] Among them, polyether polyol A is prepared by polyaddition reaction with trimethylolpropane as the initiator, and is a propylene oxide-ethylene oxide block with a propylene oxide content of 80% and a number average molecular weight of 8000. Copolyether; polyether polyol B is a propylene oxide ethylene oxide copolyether with a functionality of 2 and a number-average molecular weight of 4000 from Jiangsu Zhongshan Chemical Co., Ltd. Ethylene glycol monomethyl ether is prepared by polyaddition reaction as the initiator. It is a propylene oxide ethylene oxide random copolyether ...

example 3

[0063] The polyether composition for preparing reticulated polyurethane foam consists of the following components in parts by weight:

[0064] Polyether polyol A: 80 parts,

[0065] Polyether polyol B: 15 parts,

[0066] Polyether polyol C: 4.5 parts,

[0067] Polymer polyol D: 5 parts,

[0068] Foam stabilizer: 1.5 parts,

[0069] Amine catalyst: 0.2 parts,

[0070] Gel catalyst: 0.56 parts.

[0071] Wherein the polyether polyol A is prepared by polyaddition reaction with pentaerythritol as an initiator, and is a random copolyether of propylene oxide and ethylene oxide with a propylene oxide content of 63% and a number average molecular weight of 6000; polyether Polyol B is prepared by polyaddition reaction with diethylene glycol as the initiator, and is a random copolyether of propylene oxide and ethylene oxide with a propylene oxide content of 75% and a number average molecular weight of 2000; polyether Polyol C is prepared by polyaddition reaction with n-butanol as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com