A one-bath processing method for towel desizing and polishing

A processing technology and desizing technology, which is applied in the application field of biological enzyme preparations, can solve the problems of inconsistent temperature, inconsistent pH value range, shortening process time, etc., and achieves the effect of reducing usage, improving polishing effect and shortening process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

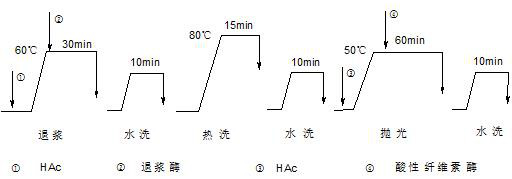

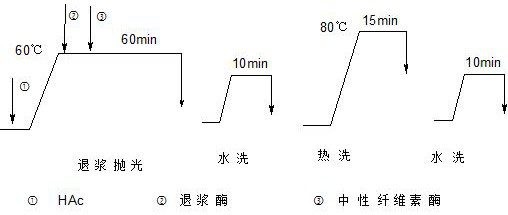

Image

Examples

Embodiment 1

[0037] Example 1: One-bath processing technology for desizing and polishing yarn-dyed towels

[0038] Towel: 123Kg Yarn count: 20S cotton dyed yarn Liquor ratio: 1:15

[0039] Model: Sanji room temperature overflow dyeing machine

[0040] Medium temperature desizing enzyme UTA-533: 0.5g / L

[0041] Neutral cellulase UTA-988: 0.3g / L

[0042] The above-mentioned medium temperature desizing enzyme UTA-533 and neutral cellulase UTA-988 were purchased from Hunan Youtel Biochemical Co., Ltd.

[0043] pH value 6.0, temperature: 55°C, time: 60min

[0044] The process steps are as follows:

[0045] (1) First add HAc at room temperature, then raise the temperature to 55°C, test the pH value of the solution, control the pH value at 6.0 (adjust the pH value of the solution to 6.0 by adding HAc), then add medium temperature desizing enzyme UTA-533 and neutral Cellulase UTA-988, run for another 60 minutes;

[0046] (2) Wash with water for 5 minutes;

[0047] (3) Hot wash at 70°C for 1...

Embodiment 2

[0050] Example 2: One-bath processing technology for desizing and polishing yarn-dyed towels

[0051] Towel: 186Kg Yarn count: 21S cotton rayon blended dyed yarn Liquor ratio: 1:12

[0052] Model: Weixi normal temperature overflow dyeing machine

[0053]Medium temperature desizing enzyme UTA-533: 0.5g / L

[0054] Neutral cellulase UTA-T12: 0.35g / L

[0055] The above-mentioned medium temperature desizing enzyme UTA-533 and neutral cellulase UTA-T12 were purchased from Hunan Youtel Biochemical Co., Ltd.

[0056] pH value 6.8, temperature: 60°C, time: 60min

[0057] The process steps are as follows:

[0058] (1) First add HAc at room temperature, then raise the temperature to 60°C, test the pH value of the solution, control the pH value at 6.8 (adjust the pH value of the solution to 6.8 by adding HAc), then add medium temperature desizing enzyme UTA-533 and neutral Cellulase UTA-988, run for another 60 minutes;

[0059] (2) Wash with water for 10 minutes;

[0060] (3) Hot w...

Embodiment 3

[0063] Example 3: One-bath processing technology for desizing and polishing yarn-dyed towels

[0064] Towel: 30Kg Yarn count: 21S cotton dyed yarn Liquor ratio: 1:15

[0065] Model: Fong's Normal Temperature Overflow Dyeing Machine

[0066] Medium and high temperature desizing enzyme UTA-576: 0.10g / L

[0067] Neutral cellulase UTA-977: 0.15g / L

[0068] The above medium and high temperature desizing enzyme UTA-576 and neutral cellulase UTA-977 were purchased from Hunan Youtel Biochemical Co., Ltd.

[0069] pH value 7.5, temperature 65°C, time: 75min

[0070] The process steps are as follows:

[0071] (1) First add HAc at room temperature, then raise the temperature to 65°C, test the pH value of the solution, control the pH value at 7.5 (adjust the pH value of the solution to 7.5 by adding HAc), then add medium temperature desizing enzyme UTA-533 and neutral Cellulase UTA-988, run for another 75 minutes;

[0072] (2) Wash with water for 8 minutes;

[0073] (3) Hot wash at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com