Method for reinforcing beam-column joint of frame structure combining ECC and steel-encasing plates

A frame structure and beam-column joint technology, which is applied in building construction, building maintenance, climate change adaptation, etc., can solve the problems of poor steel adhesion, large shrinkage, and affecting the interaction between steel sleeves and original components. To achieve the effect of improving bearing capacity and deformation capacity, good steel bonding shape, and good aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

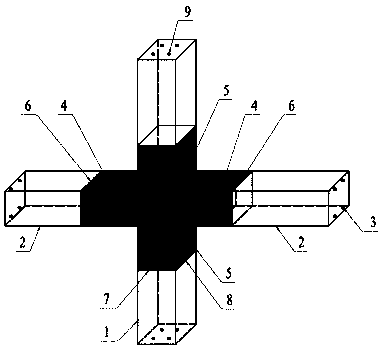

[0023] Embodiment 1: as figure 1 As shown, (1) The broken concrete blocks in the frame structure are chiseled off, and the surface of the chiseled area is cleaned. The chiseled area includes the column body area 5 and the beam body area 4. The new concrete surface needs to be washed with tap water during the chiseling process. Use a wire brush to remove the loose powder layer while punching to ensure that the cleaned interface has a certain roughness. The depth of the chisel is determined according to the degree of damage.

[0024] (2) Paste outsourcing steel plates around the cleaned chiseled area, and weld each steel plate into a whole

[0025] Outsourcing steel sleeve; the length of the steel plate is slightly longer than the actual length of reinforcement, so the distance of chiseling in step 1 should be equal to the length of the steel plate;

[0026] (3) Fill the pre-prepared ECC into the gap between the outer steel sleeve and the chiseled area and then perform maintena...

Embodiment 2

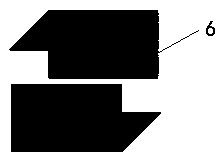

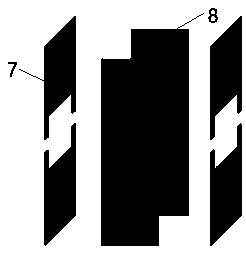

[0028] Embodiment 2: as figure 2 and 3 As shown, the outsourcing rigid cover includes two beam body steel sleeves and a column body steel sleeve, and the beam body steel sleeve and the column body steel sleeve are welded and fixed, wherein the beam body steel sleeve is composed of two L-shaped steel plates 6, The two L-shaped steel plates 6 are spliced by welding to form a wrapping layer that is attached to the beam body area 4; the steel sleeve of the column body includes two rectangular steel plates 7 and four steel plates 8 with grooves. Since the column 1 and the beam 2 intersect There is a difference in size, that is, the width of the column 1 is different from that of the beam 2, so a steel plate 8 with grooves is used, and two rectangular steel plates 7 are respectively fixed on the front and rear sides of the column body area 5, and four steel plates 8 with grooves Two by two groups are fixed on the left and right sides of the column body area 5 respectively.

[0...

Embodiment 3

[0032] Example 3: The ECC filled in this example is carried out according to the mixing ratio and preparation method of Example 1 in the invention of "A High Toughness Cement-Based Composite Material" (Patent No. CN107382183). The ECC prepared with this mixing ratio has good adhesion It can better cover the plane joints between steel structures.

[0033] Through test comparison, it is found that the effect of optimizing beam-column joints combined with ECC and outsourcing steel plates is better than that of traditional wet outsourcing steel plate reinforcement technology only. Among them, the bearing capacity is increased by about 22%. Under the action of reciprocating cyclic loading, the strength degradation of the former reinforcement method is slower than that of the latter. During the whole loading process, no obvious sliding between the outer cladding steel plate and the reinforcement area was found, indicating that the ECC and the outer cladding steel have good bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com